The project includes renovating and constructing the Theater aan de Parade in ‘s-Hertogenbosch. The starting point of the design was to partially maintain the existing concrete structure from the 1970s, with sustainability in mind. Besides the basement floor and walls, the concrete structure of the main hall also had to remain intact during the demolition of the other parts of the building. Temporary steel structures were provided at three positions to ensure the stability of the existing structure.

After the demolition phase was completed, work began on building the new structure, which started with the installation of 129 st. jet grout piles under the existing basement floor. A new steel structure was then placed along and over the carcass of the main hall, including four large trusses, each over 20m long and weighing over 7 tons, for the new roof structure.

Behind the main hall, the stage tower was completely rebuilt, consisting of a combination of steel and concrete. In the back wall of the stage tower are 5 st. HEB800 columns (each with a height of almost 22m), resting on trusses, each almost 20m long and weighing over 9 tons. These trusses support both the hollow-core slabs of the roof and the slatted floor of the roller loft for theater technology. In addition to the large auditorium with a stage tower, this building also contains a center hall with height-adjustable floors and retractable bleachers. Thus, this hall is suitable for both a theater performance and the famous Oeteldonk Carnaval. This construction is designed as a box-in-box (both the steel construction and the floor of the inner box are acoustically decoupled from the surrounding concrete construction) so that both halls can be used simultaneously.

What makes this project special is the integrality of the many installations, not only the complex building installations required for a theater, but also the many technical theater installations. For example, the central auditorium is equipped with a lifter, with which a complete truck combination of 10 tons can be raised about 4.5 m indoors. This allows props to be moved directly from the trailer to the stage without bridging height differences. Supplying the large auditorium will take place by means of a sliding platform on which two articulated lorries can be moved in from outside the building, so that loading and unloading can also take place behind closed doors (without disturbing the surroundings).

The entire steel structure of over 900 tons was constructed in Consequence Class CC3 with a unity check of 0.83 on the key elements designated by the designing structural engineer. In addition to the aforementioned columns and trusses, the project also includes various stairs and railings, with the main staircase at the heart of the building as the eye-catcher. This staircase connects the basement to the ground and 1st floors, the total weight is no less than 22 tons.

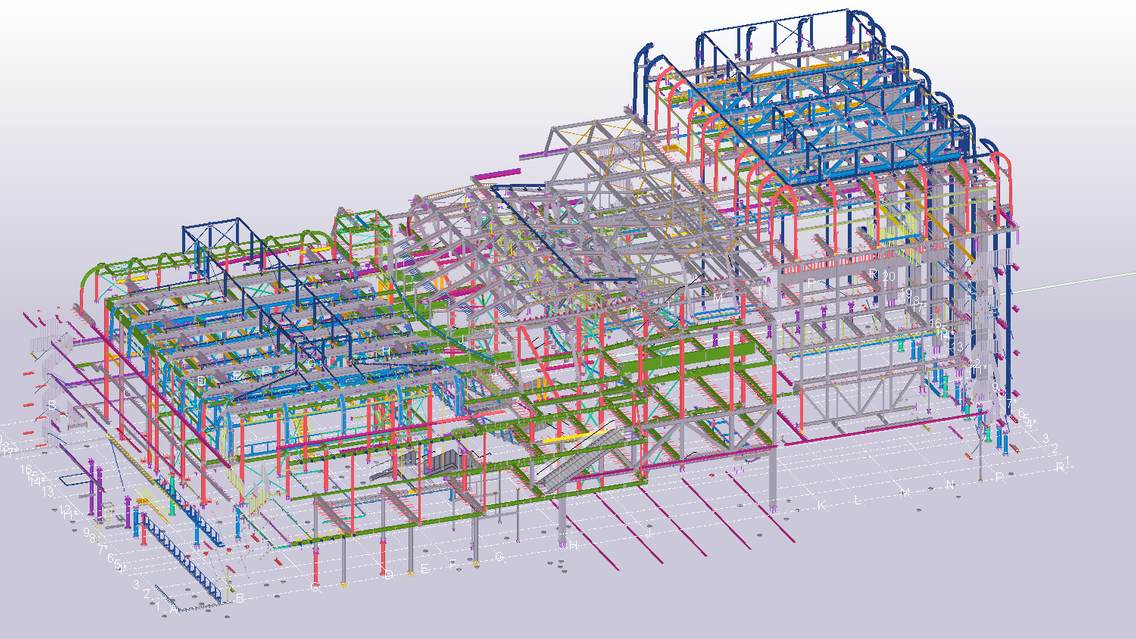

In addition to the steel structure, the concrete structure, building installations (E – W – S), theatrical installations, architectural finishes and various large components (e.g. floors, precast stairs and precast facade elements) were also worked out in 3D. IFC models were merged into a total model. Dalux is used for this purpose, with which both the IFC models and other documents are shared centrally and easily.