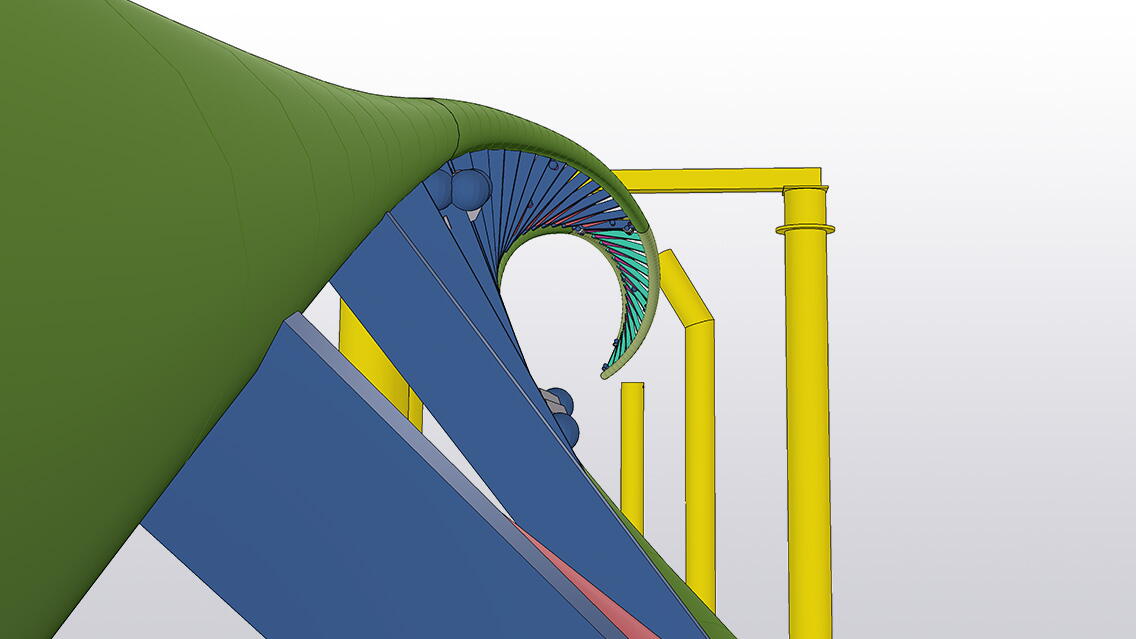

Thorpe Park commissioned TAZIKER to undertake the re-tracking of two sections and a support column on the Colossus rollercoaster. These sections were situated within the heartline roll segment, a pivotal portion of the coaster where riders experience a 360-degree rotation around the axis of their heart. The decision to replace these tracks was made in accordance with the park's maintenance protocol, prompted by inspection reports signalling the gradual deterioration of the tracks nearing the end of their operational lifespan.

Challenges and achievements

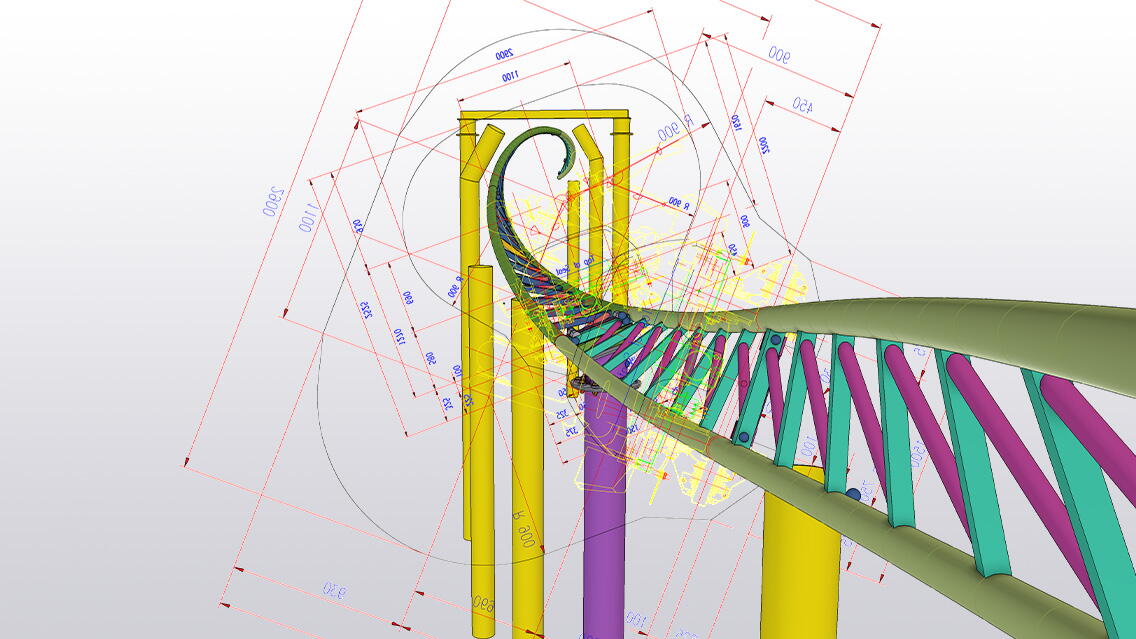

The intricate geometrical nature of the Colossus rollercoaster track design posed a significant challenge, as it was engineered to allow riders to rotate around the axis of their heart. In an orthogonal plane section view, the track is a perfect circle, demanding precise replication of existing geometry. Upon removal of the old tracks, the support columns exhibited a surprising 120mm deflection.

The best course of action started with the creation of a point cloud of the tracks prior to removal. This survey data could then be used to create a jig of the column supports for the new track to sit in. The effectiveness of this method was further validated by the precise fit-up achieved when comparing the fabricated tracks to the jig orientation derived from the point cloud. Leveraging Tekla's advanced layout tools, particularly the layout points and layout manager functionalities, proved instrumental in streamlining the fabrication process. Exporting the layout data to a total station was the perfect solution for accurately manufacturing these complex fabrications.

Innovative solutions were also devised to address the challenges posed by the helical shape of the tracks. A specialised Grasshopper script was developed to accurately model the tracks, accounting for variations in radius along the rolled members. This aided the creation of precise templates for the workshop, setting stops and jig work against predetermined rail positions.

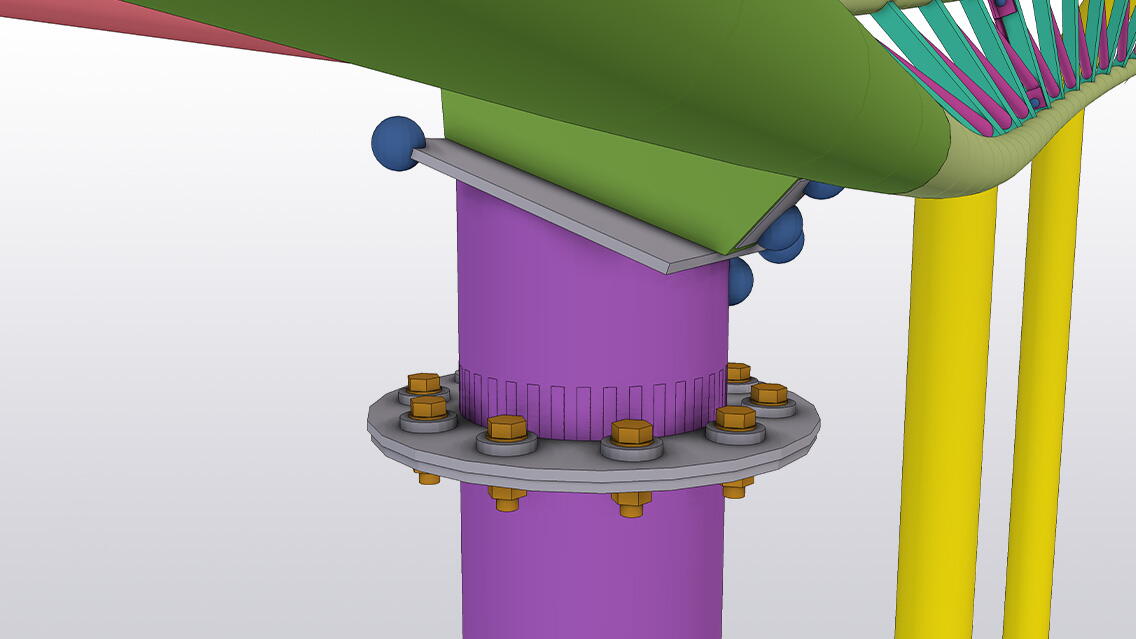

A new support column was also designed, featuring a removable head to accommodate site tolerances during installation. The design work for the removable column head was undertaken by Westlakes Engineering.

Using Tekla software

- STEP files were exported for laser profiling sections of the track.

- An IFC was provided to the workshop to demonstrate how the tracks needed to sit in their respective jigs.