Production and delivery of prefab timber frame elements for wall and roof elements

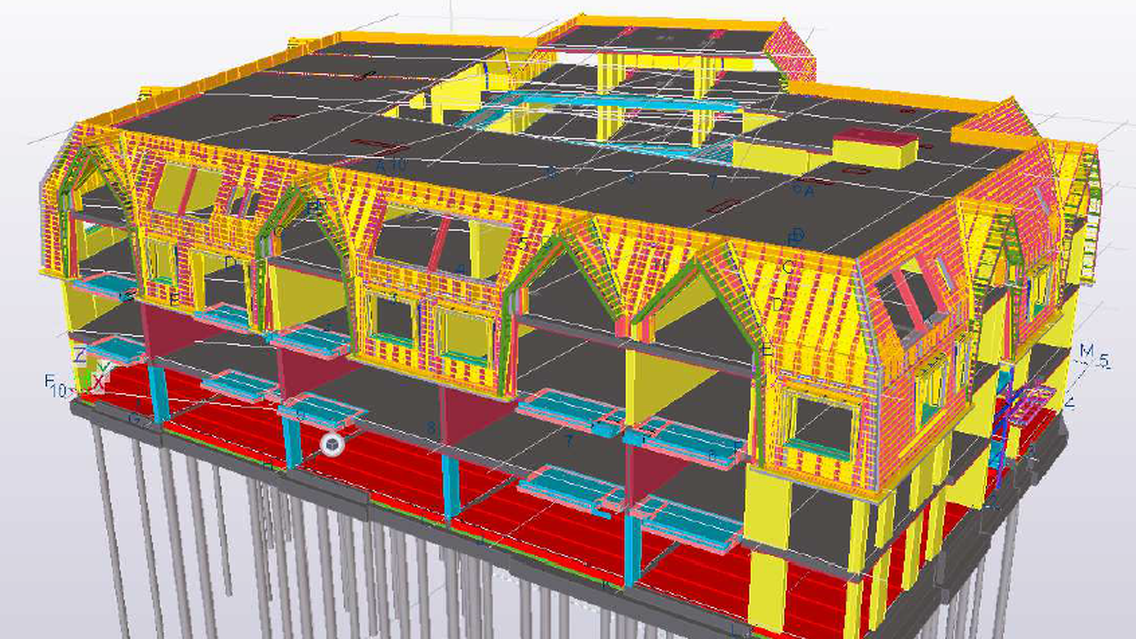

The roof elements were so complex that 2D was not workable, so Tekla Structures offered the solution here.

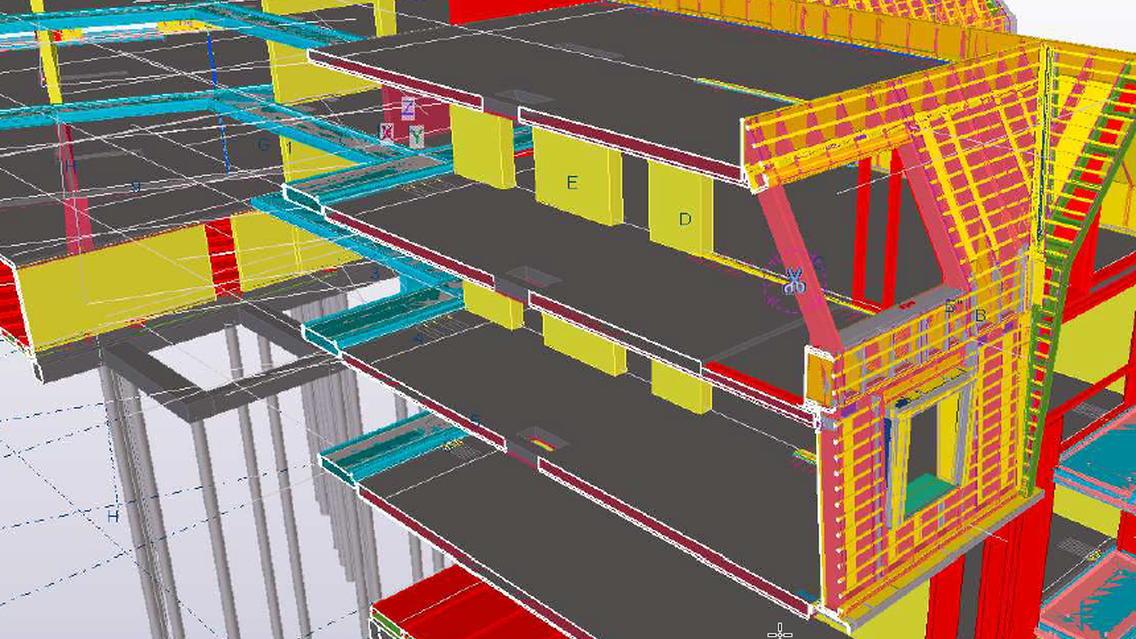

Strangely enough, this project was not adopted as a BIM project, but as a traditional 2D. That was no problem for the HSB wall and façade elements, but the roof structure (our BIM awards entry) turned out differently after a week working in 2D. When it appeared that the steel structure, sand-lime brick and prefab balconies, as well as the concrete structure, were available as IFC, we decided to complete the roof with prefabricated dormers in Tekla.

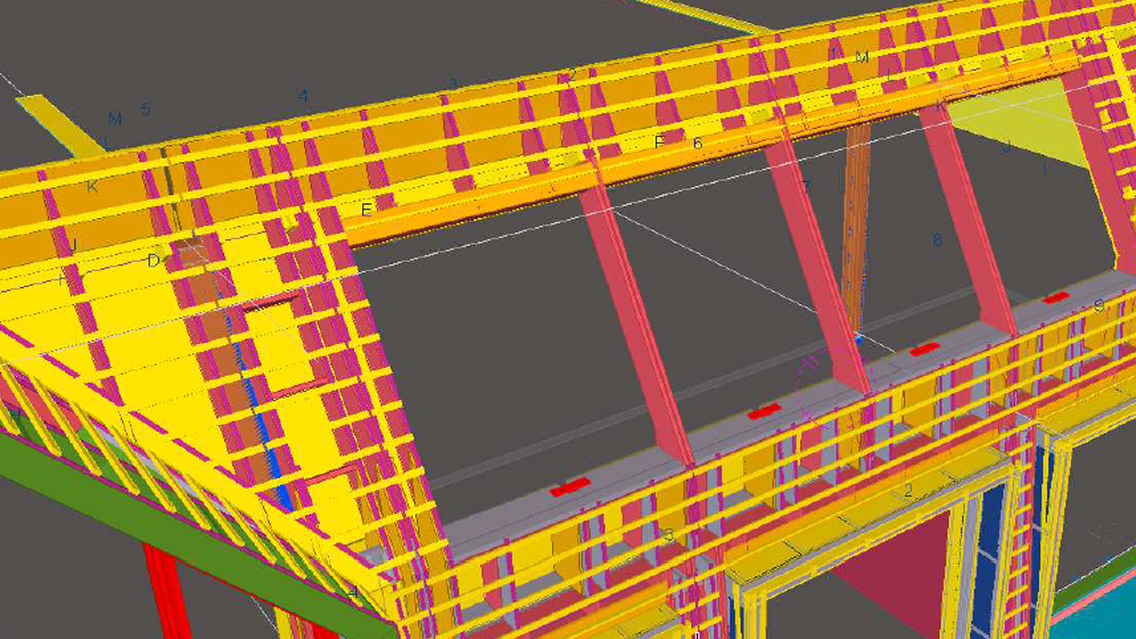

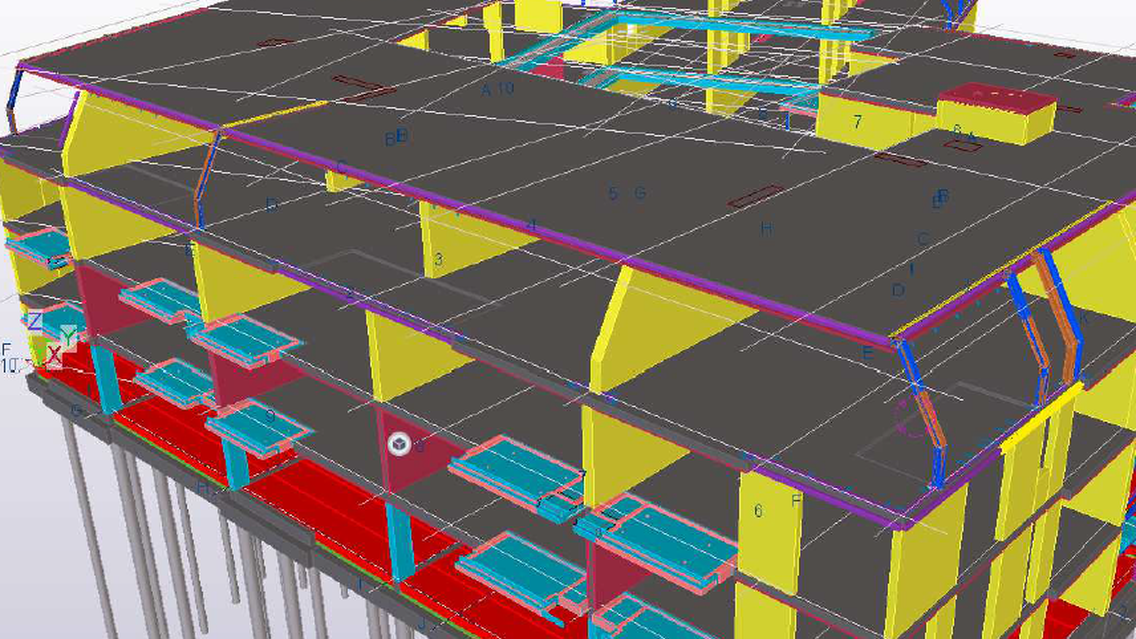

The complexity of the roof is expressed in a shell that extends over two floors and has an inclination that varies in style from almost vertical to sloping. For the first floor, the (almost vertical) roof hangs on the floor of the third floor and is supported by a gutter construction against the floor of the second floor. The top-level roof has a crippled stanchion construction on (also) the third floor and is supported on the roof floor. Perpendicular to the longitudinal hood are transverse hoods, which again have a different inclination. Detailing the hip and valley rafters was quite challenging. In addition, the dividing walls in some places had to run through the rafters. The wide balconies with large roof openings also demanded an unusual solution.

The model was built from scratch, the saw and bevel angles were generated using 3D-Trim. From the model, BVX the NC-data was exported from within Tekla so all raters were cut, sawn and beveled by the Hundegger machine. Before we proceeded to production drawings, the model was thoroughly checked for fit in relation to other relevant hull components. For production, in addition to 2D shop drawings (with 3D view), we used one IFC per assembly that was generated by the CS IFC export tool. In the workplace one could view elements from all sides via a tablet. This has ensured that the production went smoothly. The final fit at the construction site also turned out to be good – something the erection team from our client didn’t expect.