BIM approach

The model was designed from an IFC, which I imported as a reference model on Tekla. In order to position the reference model correctly, I inserted it with a georeferenced point.

Once imported, I retrieved the elements making up my sub-section and converted them into an object. I then adapted the elements to the Eurocodes checks I had carried out, designed and checked the assemblies, and edited the production elements in accordance with our BIM convention.

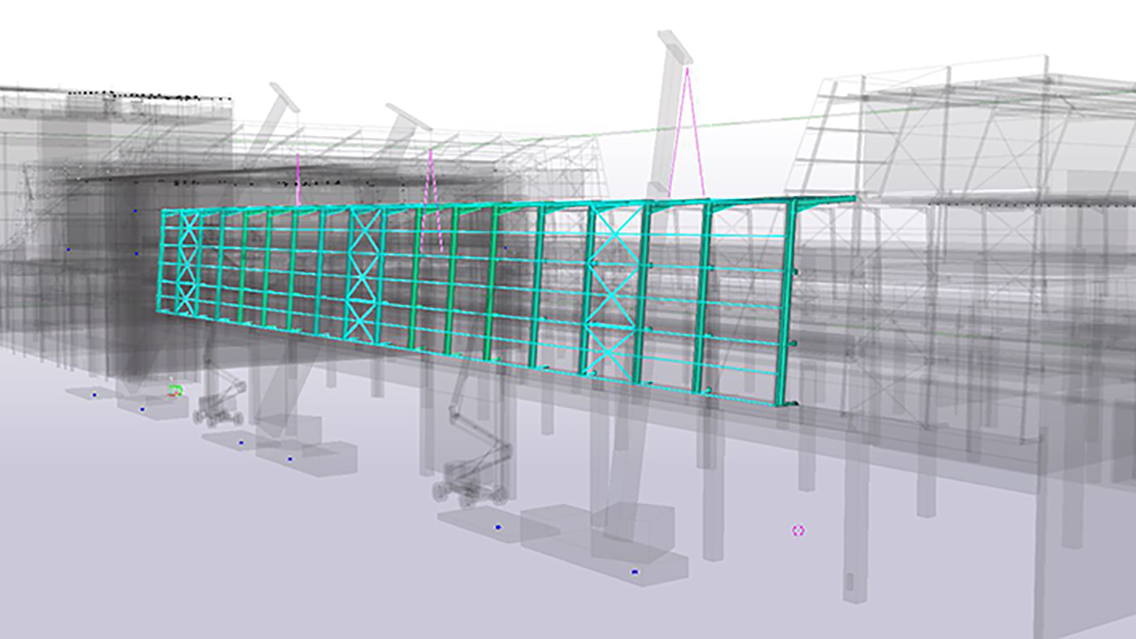

What's more, I needed to use platforms to illustrate the assembly procedures for the parking section. To do this, I used parametric BIM objects, whose parameters I had to modify via third-party software to change the height and offset of the nacelles, then exported them in IFC format to add them to the Tekla model as reference models.

Workflow - 4D study

Once the building had been modeled, I continued to use Tekla Structures for the methods office.

1. Task manager

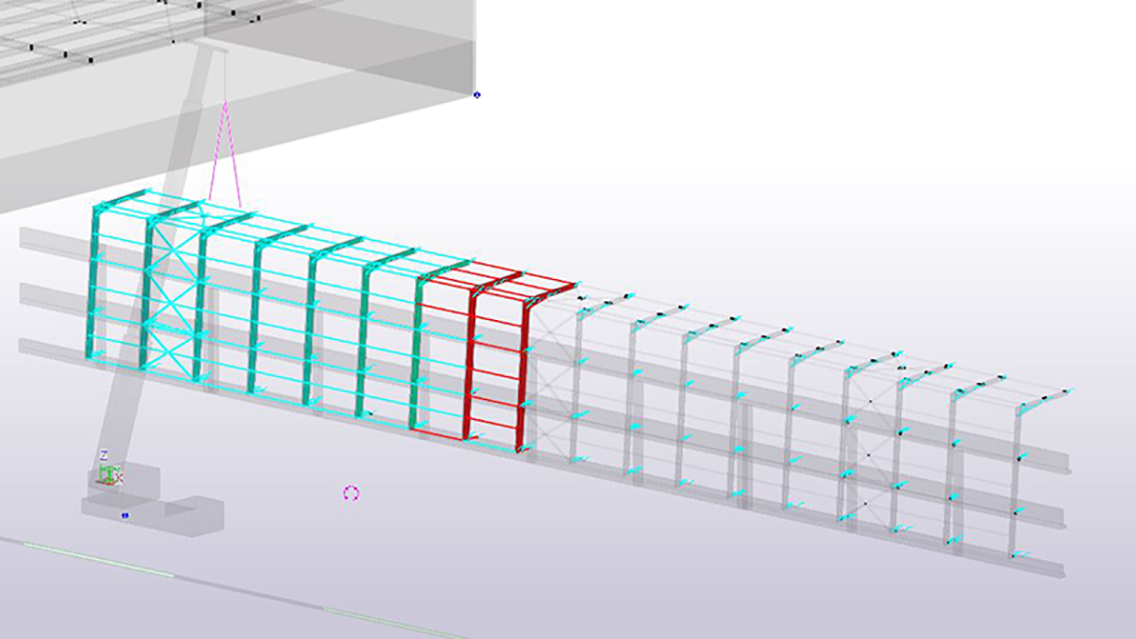

In order to visualize the progress of assembly, I imported as a scenario, in XML format, the assembly schedule previously drawn up with planning software. I then adjusted the production rate in kg/h and assigned the assemblies to their respective tasks. Finally, I produced a video illustrating the assembly phasing (BIM 4D).

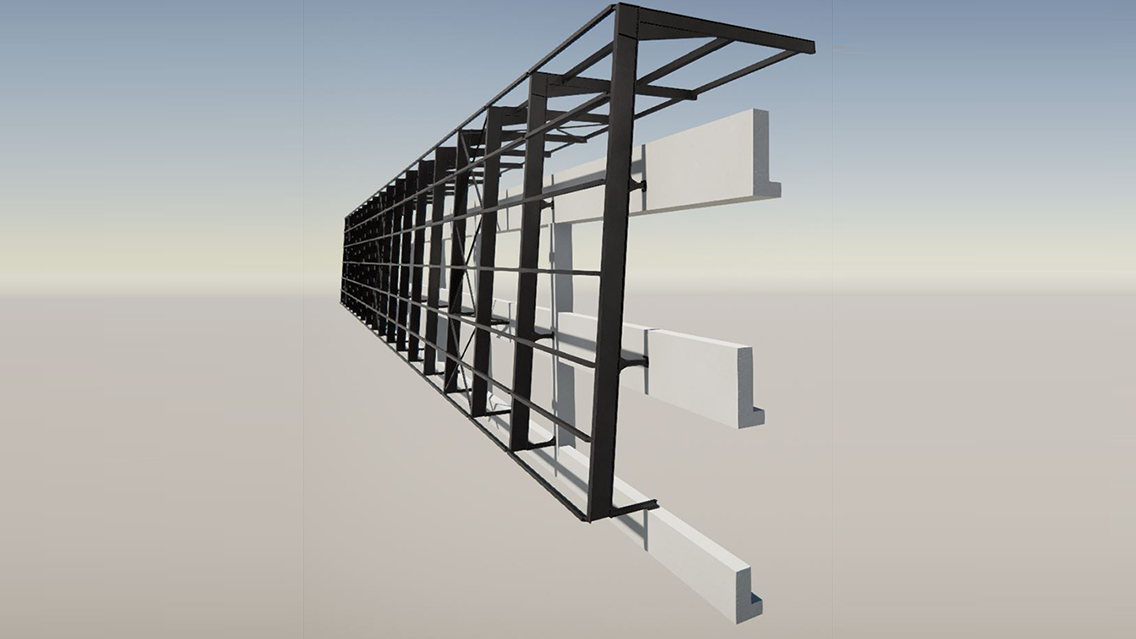

2. Packing tool

To forecast the number of trucks and define the loading order according to the assembly order.

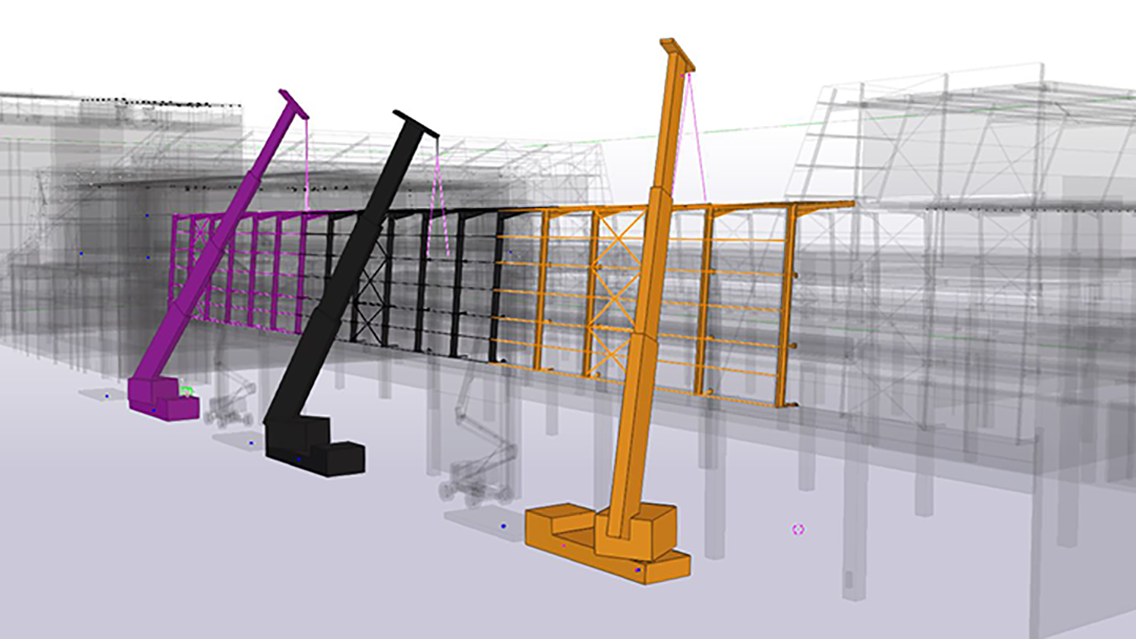

3. Crane tool (extension)

To determine the different stations of the mobile crane selected to assemble the entire parking area.