The Van Leesten Memorial Bridge was designed to be a signature destination for surrounding neighborhoods; a place to sit and reflect, socialize, and even enjoy some local entertainment. Elements such as benches, chairs, a built-in chess board, illuminated tables, cascading Busker Terrace, and a garden space that separates the upper and lower decks, were integrated to invite community connection and social engagement.

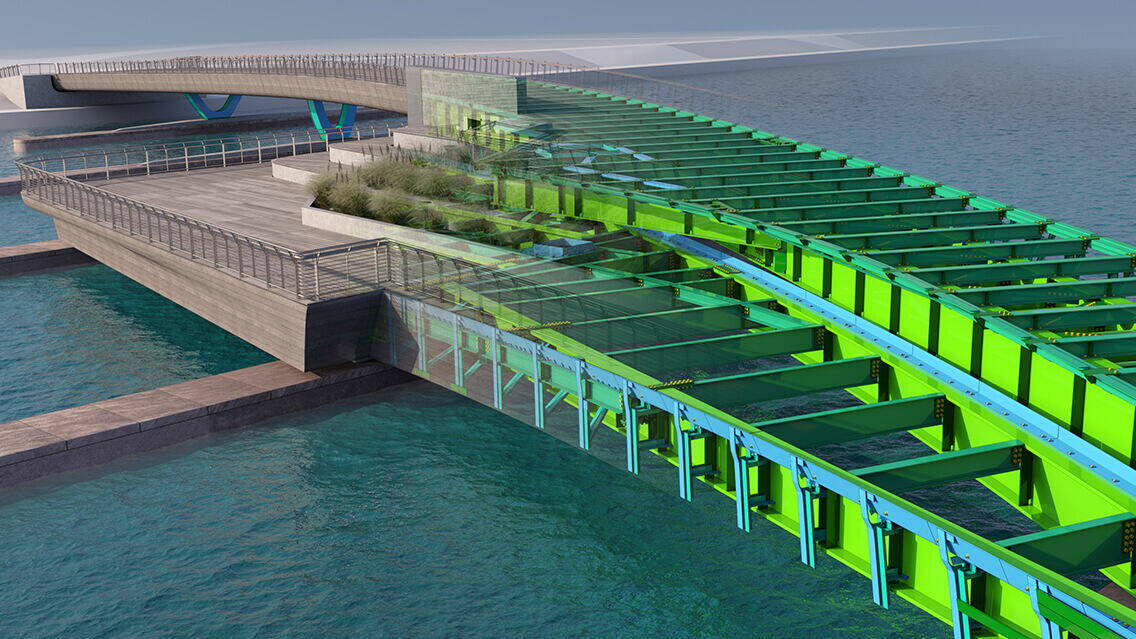

Characterized by Providence’s history of 18th-century tall wooden ships, and the city’s 20th-century jewelry factories, timber construction played a significant role in the design intent of the pedestrian bridge. The two-level pedestrian crossing is made up of a steel superstructure, further incorporating individual planks of South American IPE wood decking along the surface, and over 208 Wana wood panels continuing onto the exterior of the structure. This results in an architectural statement overlooking the riverfront and a beautiful view of the city’s skyline.

Challenges and achievements

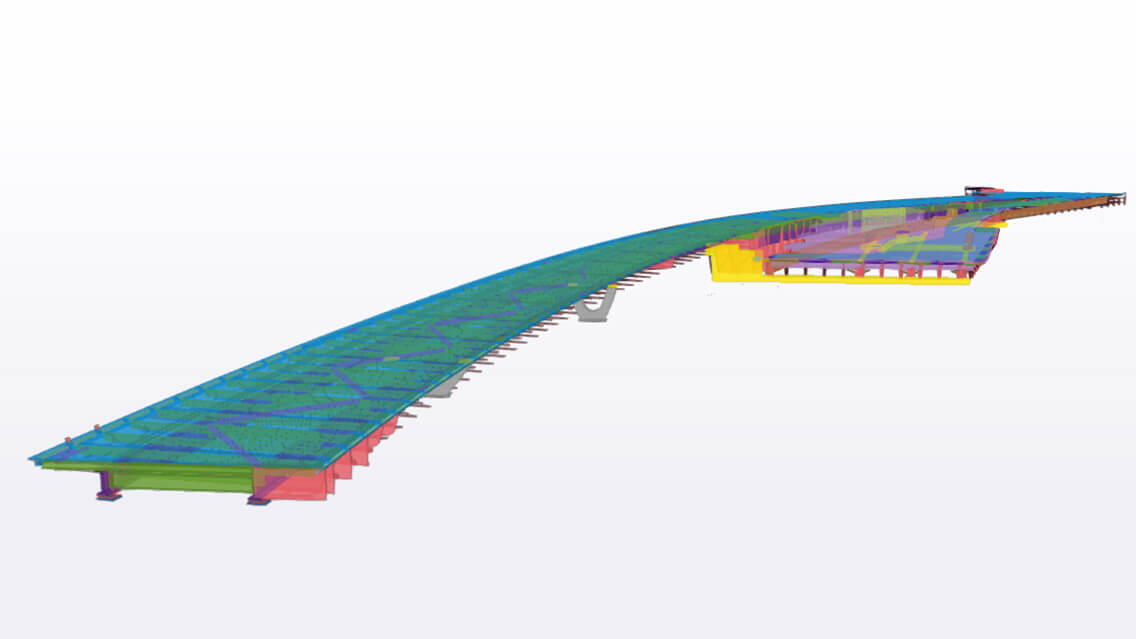

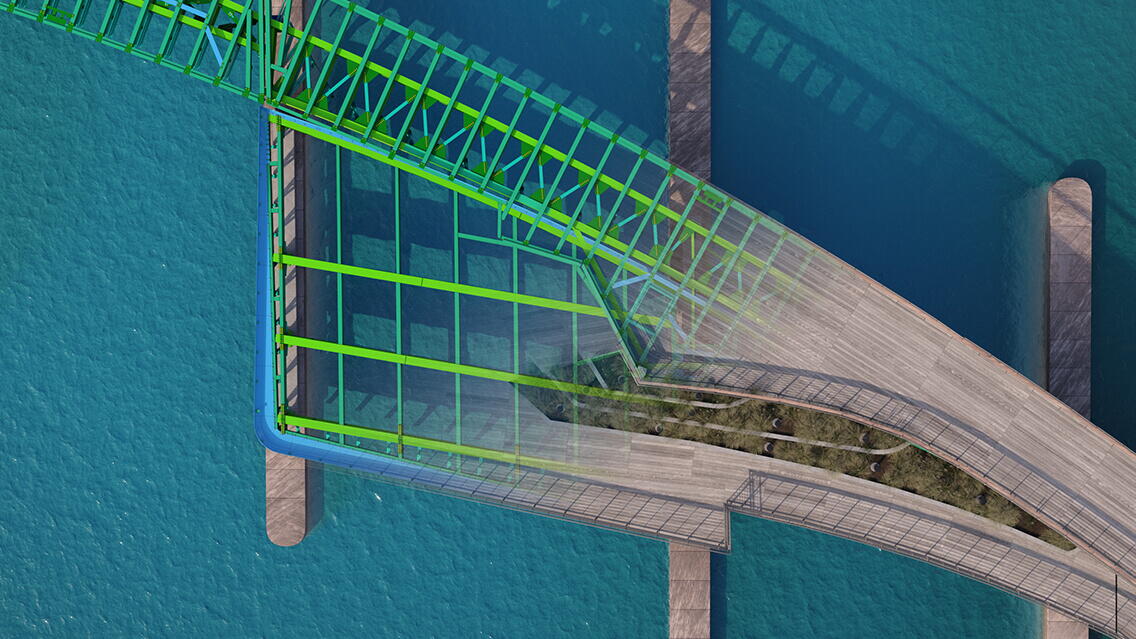

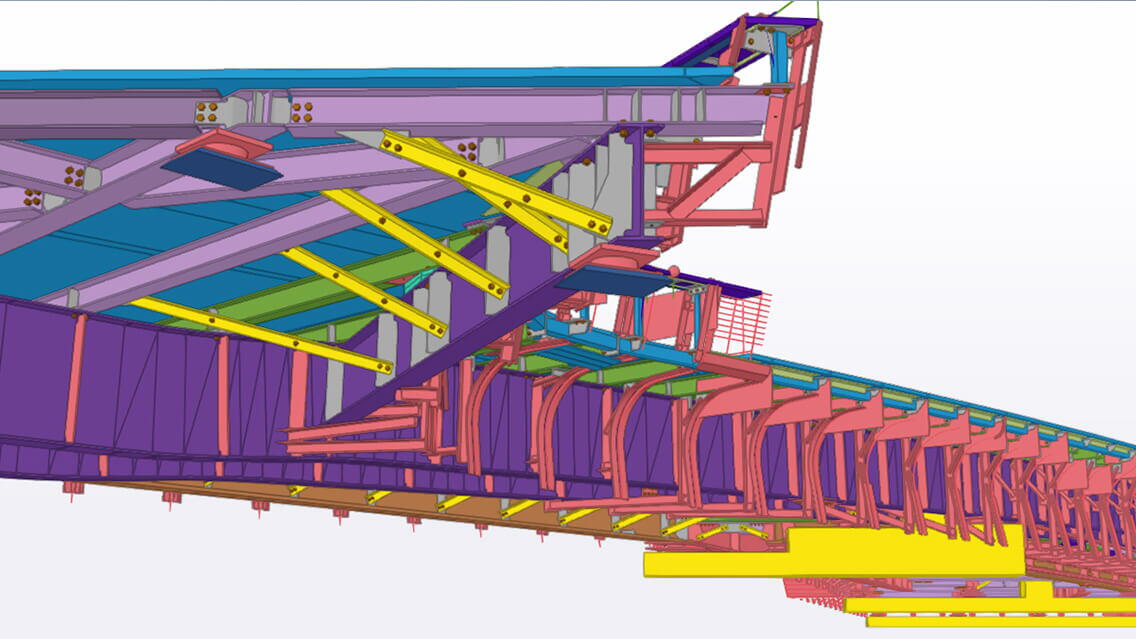

- Complex Geometry - The primary challenge of this project was the complex geometry of the multi-level steel superstructure and the individual connections of the IPE deck and Wana wood panels. With the combination of the slope and the sweep (a horizontal curvature on the bridge), as well as the many irregular shapes, and curves in different directions, DBM Vircon had to create camber values for each of the girders on the steel superstructure. Once these values were integrated into the Tekla model, individual connections for the IPE wood decking and the Wana wood panels also had to be created. Due to a large curve towards the lower end of the bridge, the handrails that doubled as pedestrian guards also presented a challenge with the unique connections taking time to determine. Referencing the architectural model provided, DBM Vircon interpreted the design intent to determine where the curves start and finish, in order to further simplify the geometry and ensure the project could be fabricated accurately and in a timely matter.

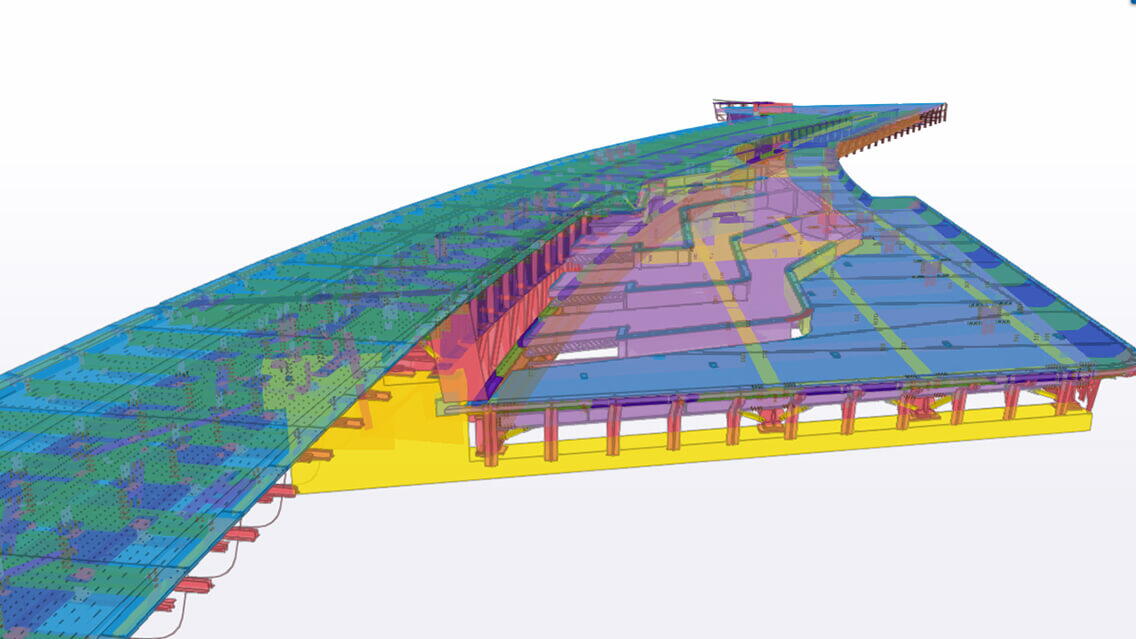

- Multiple Materials - The architectural appeal for the Van-Leesten Memorial bridge was to emulate the 18th-century wooden ships that once passed through Providence. The IPE wood decking that was modeled and detailed presented a challenge as each individual panel had its own shape and size – DBM Vircon had to locate each of these IPE wood planks integrating them with the proper support below. A total of 208 exterior Wana wood panels also had to be connected to the exterior of the bridge superstructure. Each individual Wana wood panel was uniquely shaped and had to be bolted into place on specific locations on the girders of the steel superstructure. Many sketches were generated, and meetings held to work out these unique connections and details. Panel framing that attached to these connections were added as reference to the Tekla model so that there were workable connections for the fascia Wana wood panel framing. The Tekla model then became the major source of communication between multiple stakeholders.

- Multi-Level & Integrated Elements - The Van-Leesten Memorial bridge was designed with a blunt elevation – a higher level that merges into a lower-level cascading down towards the water. In addition to the vertical elevation, there was also a horizontal curvature of the bridge (sweep) that posed difficulty with the integrated architectural elements of the bridge. There were many things to consider within a small space – particularly, the integrated elements such as the lighting underneath the hand railings, the benches, chairs, tables and built-in chessboard, all which had unique connections and locations on the steel superstructure. These connections were made whilst still considering the garden space that separated upper and lower levels, and cascading terrace of the two-level structure. Because of the limited spacing and curved members of all different shapes and sizes, typical connections to the superstructure were not applicable. The use of Tekla allowed DBM Vircon to create the unique connections for all of the integrated elements.

Using Tekla software

- Enhanced Collaboration and Constructability - The use of DBM Vircon's 3D Tekla model facilitated collaboration between multiple project stakeholders, enabling the team to deliver a superior design solution within the tight project constraints. The project stakeholders worked very closely with DBM Vircon’s team in a collaborative design assist process to ensure fabrication and constructability of the complex geometry of the entire superstructure and the IPE wood planks, all curving in multiple directions. It was essential that 3D geometry models were available in conjunction with the architectural model that was provided. The 3D geometry models ensured that all project stakeholders had a clear, unified understanding of design intent, so that early-stage designs could be modified to achieve optimal steelwork outcomes and minimize costly changes during fabrication and erection, thereby saving time and money, all while reducing risk. DBM Vircon’s Tekla model was used to check clashes between the steel superstructure and the architectural model provided. There were several instances where elements clashed; the Tekla model ensured that these clashes were found and rectified early on in the construction process. This helped to reduce on-site costs, improve scheduling certainty and de-risk the project.

- Streamlined Fabrication Process - DBM Vircon utilized Tekla to export files for the fabrication of the steel superstructure and IPE planks and Wana wood panels of the Van Leesten Pedestrian Bridge. With over 200 uniquely shaped Wana wood panels required for the construction of this highly unique bridge structure, the use of Tekla helped to ensure that the panels fit perfectly to the girders of the steel superstructure during erection. By eradicating clashes and constructability inconsistencies, rework and delays were significantly reduced for the bridge’s fabricators, improving scheduling certainty and reducing costs associated with rework and variations. The integrated Tekla model improved efficiencies across the project’s construction lifecycle through parallel workflows and reduced duplication.