Vinhomes Landmark 81 is situated in Tan Cang, the city center, and adjacent to Vietnam's tallest building and Saigon's new symbol of prosperity. It will be the tallest in the Indochina Peninsula and the 14th tallest in the world where one can enjoy the tranquil panoramic river views. Inspired by the image of bamboo – a traditional plant symbolizing strength and unity, Landmark 81 is elegantly shaped to reach up to the vast blue sky, marking an era of prosperity and the people’s aspiration for greatness.

With a height of over 460m, this will be the tallest building in Vietnam. The 81-story development is located in Vinhomes Central Park - one of the most prime locations in Ho Chi Minh City, Vietnam. Its frontage faces the beautiful Saigon River, and is conveniently connected via major road and water transportation. Featuring a modern and unusual architectural design that symbolizes the diversity and fast-emergence of Ho Chi Minh City, this mixed-use development includes space for a hotel, serviced residential apartments and retail stores. At the base of this skyscraper is a sumptuous shopping center featuring the finest retailers under one roof for a top-class shopping experience. The 241,000m2 development will also feature contemporary landscape design that merges natural beauty into this building. The construction of Vincom Landmark 81 is expected to be completed in 2018.

Types of Development:

+ (B1, F1, F2, F3): Commercial center, cinema, indoor skating rink.

+ 4th Floor: Club house area for residents including pool, gym, spa + 5th Floor: Five-star lounge and community center for residents.

+ 6th to 40th Floor: Luxury apartments with 1-4 bedroom apartments.

+ 42nd to 76th Floor: Vinpearl five-star Hotel (42nd to 76th Floor).

+ 79th to 81st Floor: Skydeck Observatory (79th to 81st Floor).

Coteccons is honored to be the first Vietnamese general contractor that has finished this project 30 days ahead of the agreed schedule from the basement to topping out of the superstructure.

Challenges that Coteccons faced

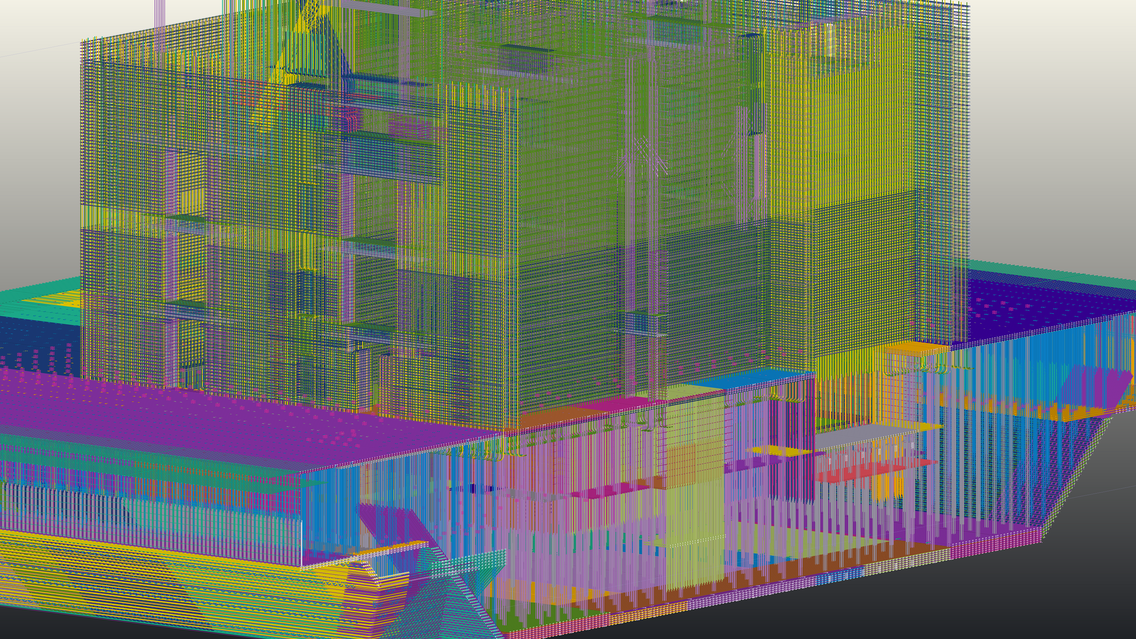

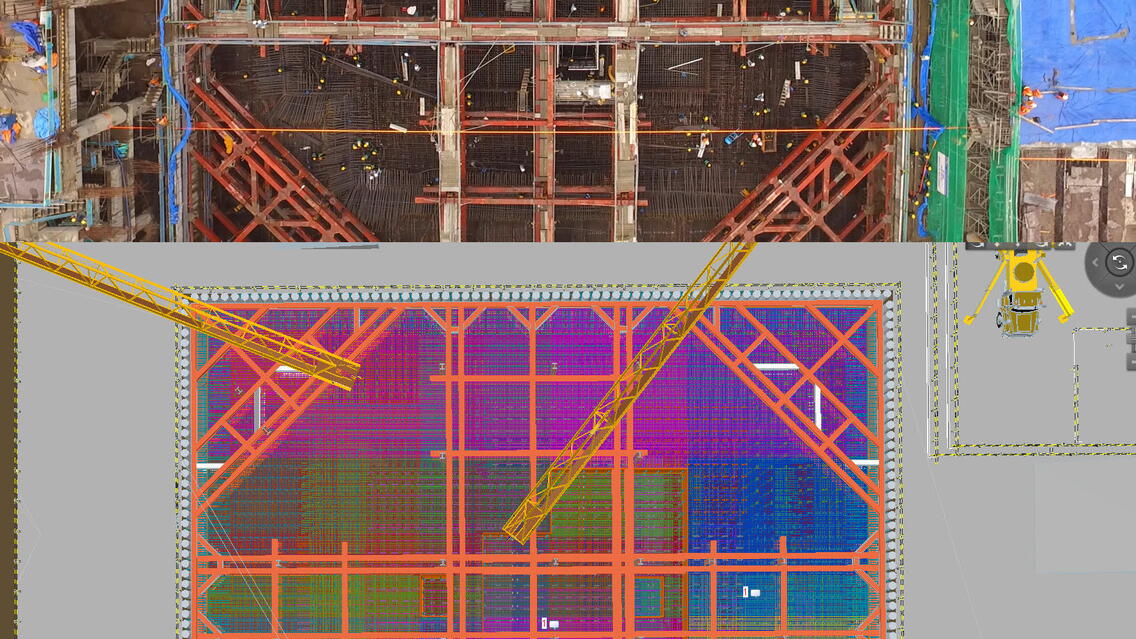

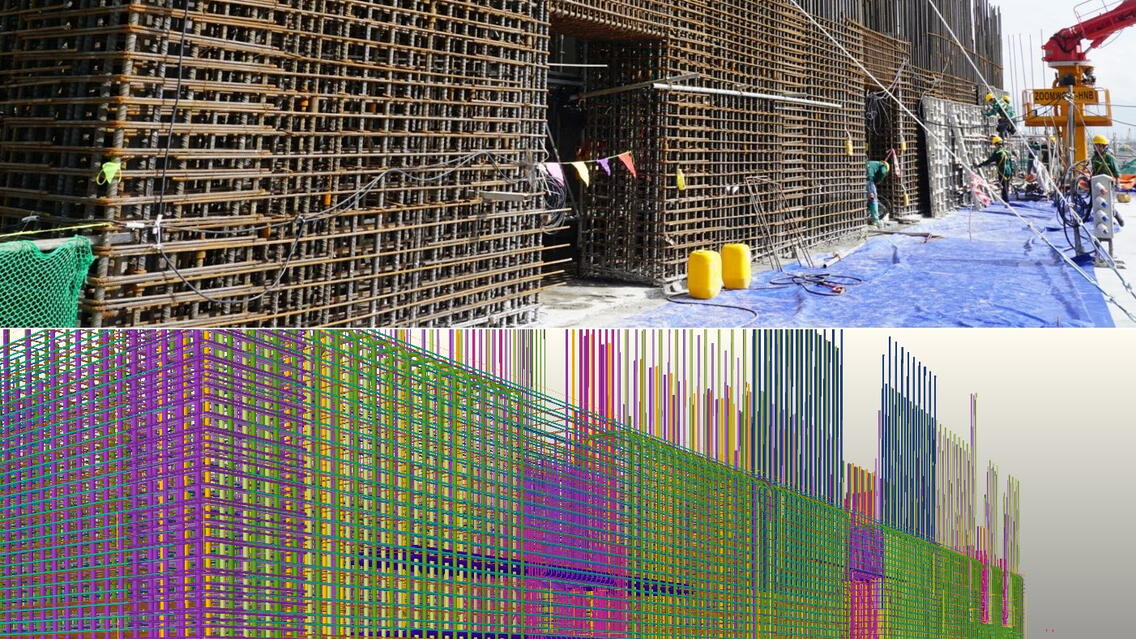

1. We were faced with the biggest mat footing ever which is over 16,000 m3, 8.8 meter high at -18.0m from Level 1, massive rebar of top, bottom layer and H400 bracing systems. The project manager required to foresee the clashes of rebar with shoring/kingpost and the slope of foundation … from that we could discuss with client/designers in changing the solution for constructability.

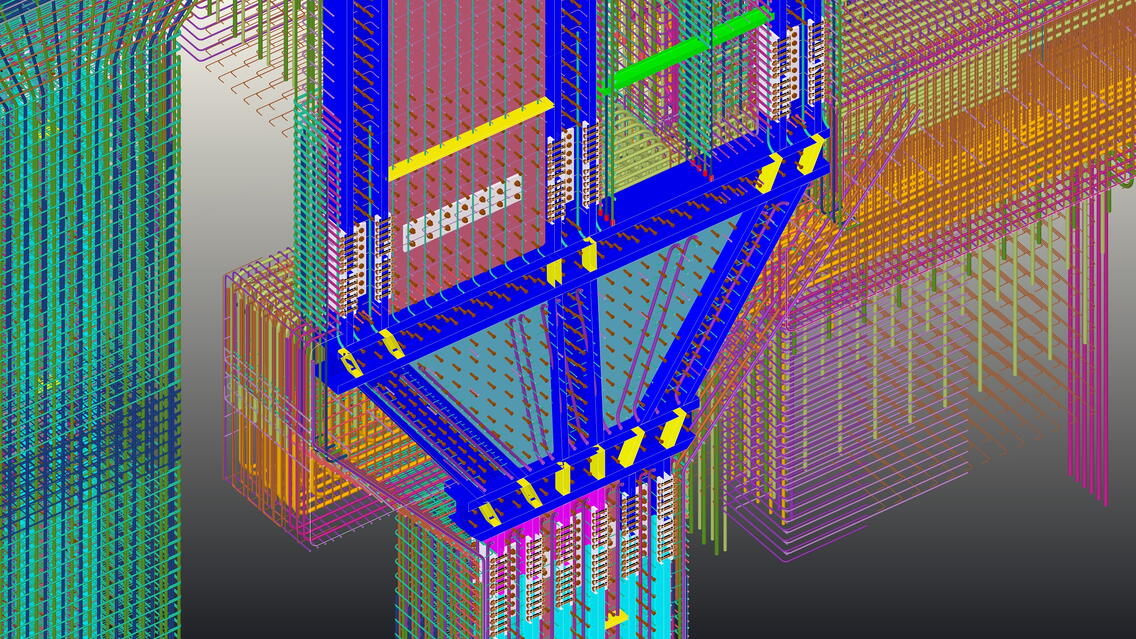

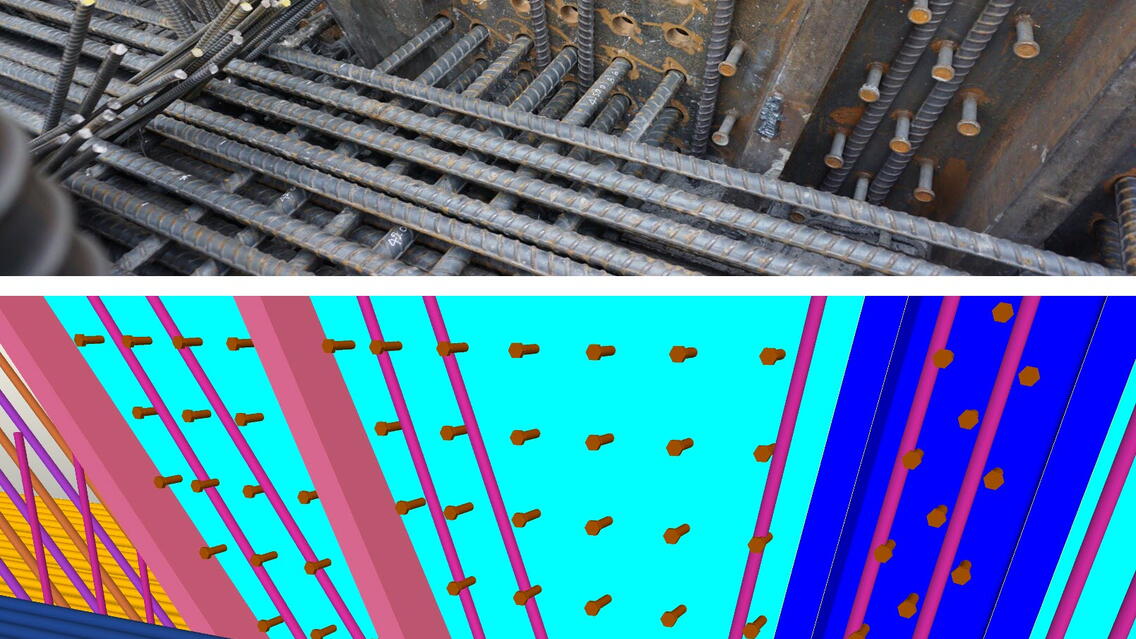

2. It is the first time we deal with the composite structure which is the combination of density rebar and steel structure including shear stud and welded coupler. This is a complex connection and requires a tool that can generate the detail of each corner, for the goal is to create 3D visualization of rebar/bolts and steel connection. It also needs precision in fabrication from the factory or cutting rebar onsite and step by step instruction for erecting.

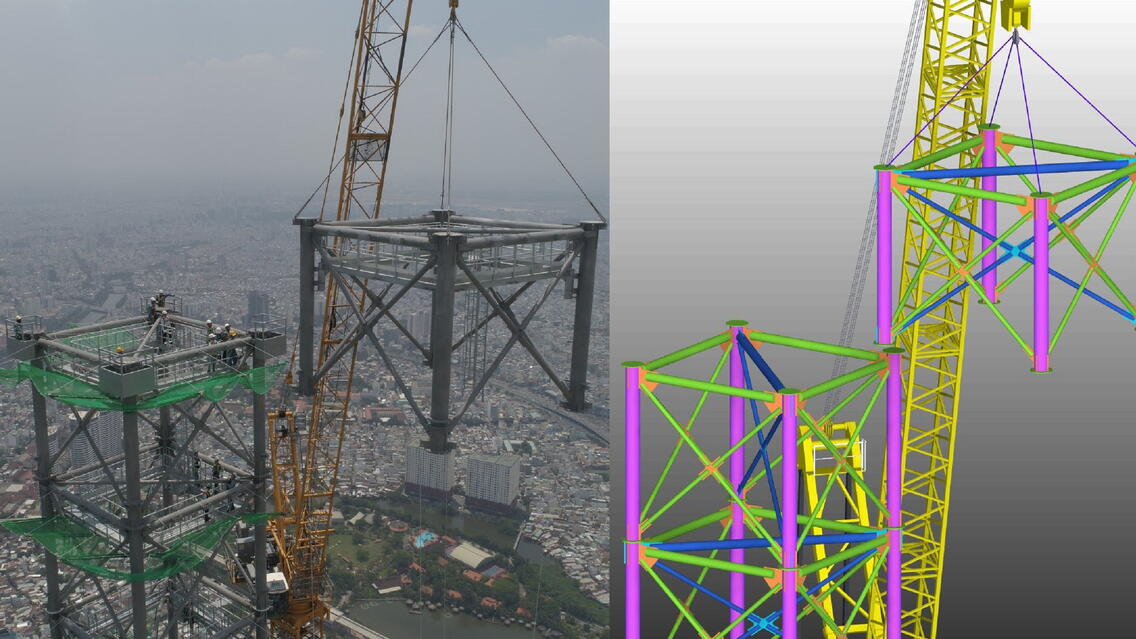

3. The last challenge is the method statement especially for the construction equipment like the tower crane, falling protections, dropping for slab at over 20m soffit height and the assembly of a spire on the rooftop. Based on these tough challenges, we need a tool that can simulate and predict each step during the installation, and on-schedule so that we can recognize the risk and make many scenarios for elimination before it is built in reality.

Success factors

Based on the tough challenges mentioned above, we are fortunate to have the factors that make a successful project.

1. The consensus and cooperation of teamwork between all partners of the project (client, consultant, general contractor, subcontractor and designer).

2. The management board has a strategic vision when using technology to apply the BIM model, especially to use the right BIM tool to deal with those challenges.

Tekla software is the most suitable choice for those conditions and we get some benefits:

1. First thing first is that the 3D BIM model from Tekla brings the clear visualization, reducing the mistakes when constructing, aiding the communication between office and site transparently.

2. Detailing rebar: flexible and exact dimension.

3. The software enables the user to create and manage 3D structural models for both steel and concrete and guides them through the process from concept to fabrication.

4. Beside Tekla, we also use the Tekla BIMsight/Trimble Connect which is a professional communication tool that supports us to improve effective collaboration in the entire construction workflow. It also allows us to combine models, check clashes and share information by using the same easy-to-use 3D environment; the result is the issues are solved already in the design phase. Moreover, our staff also use other software such as Sketchup – for simulating 3D objects in the method statement.