As part of the Monlevade contract, Allcons Industry supplied structural analysis and detail engineering for technological units of the so-called wet dedusting systém of the boiler.

Industrial dedusting has an important impact on environmental protection.

It limits the release of harmful substances into the air, which contributes to a sustainable and healthy environment.

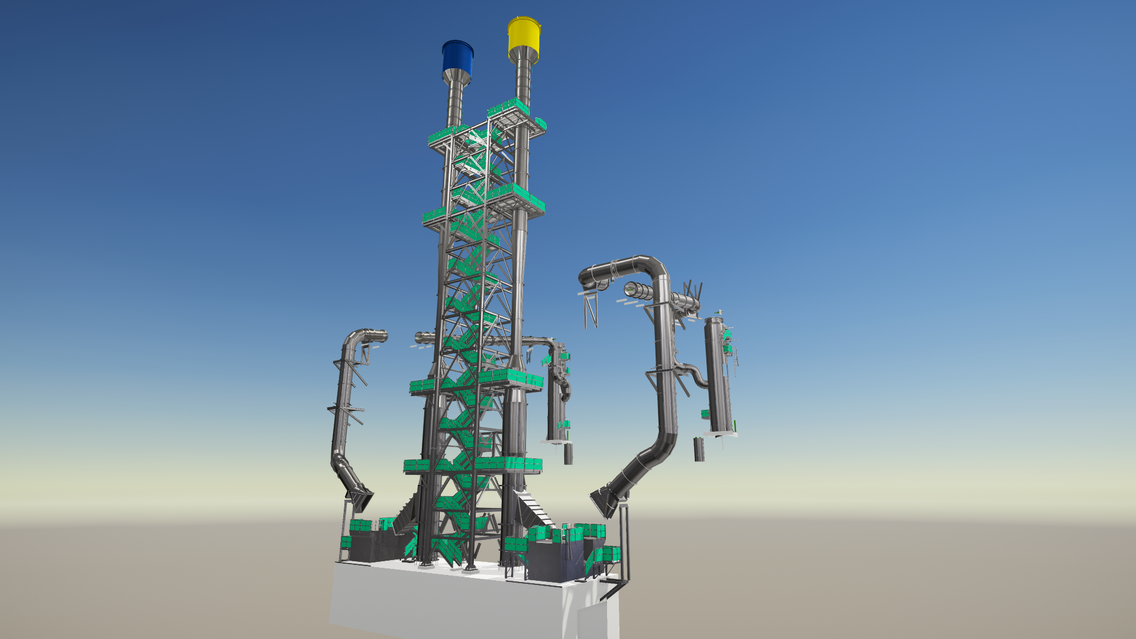

The entire structures consist of two lines, each of which consists of:

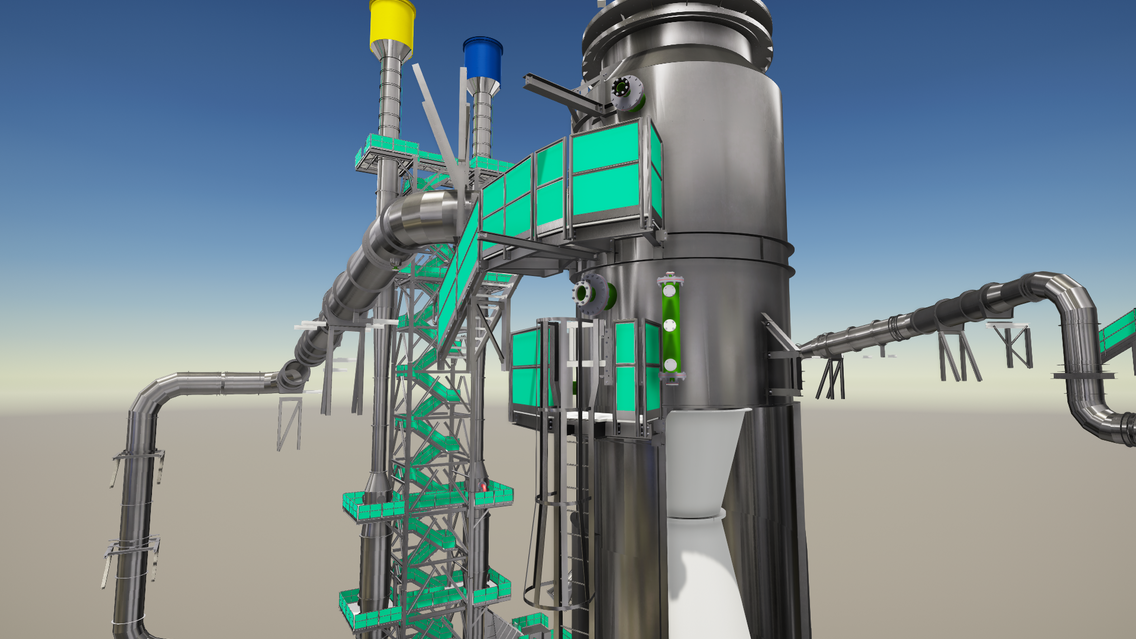

- Combined Tower (Equipment for cleaning of gas)

- Seal Pot (basically a big siphon)

- Clean gas duct

- Flare stack and its supporting structure

- Flare head

- Access platforms to ID fan

And the shared staircase tower.

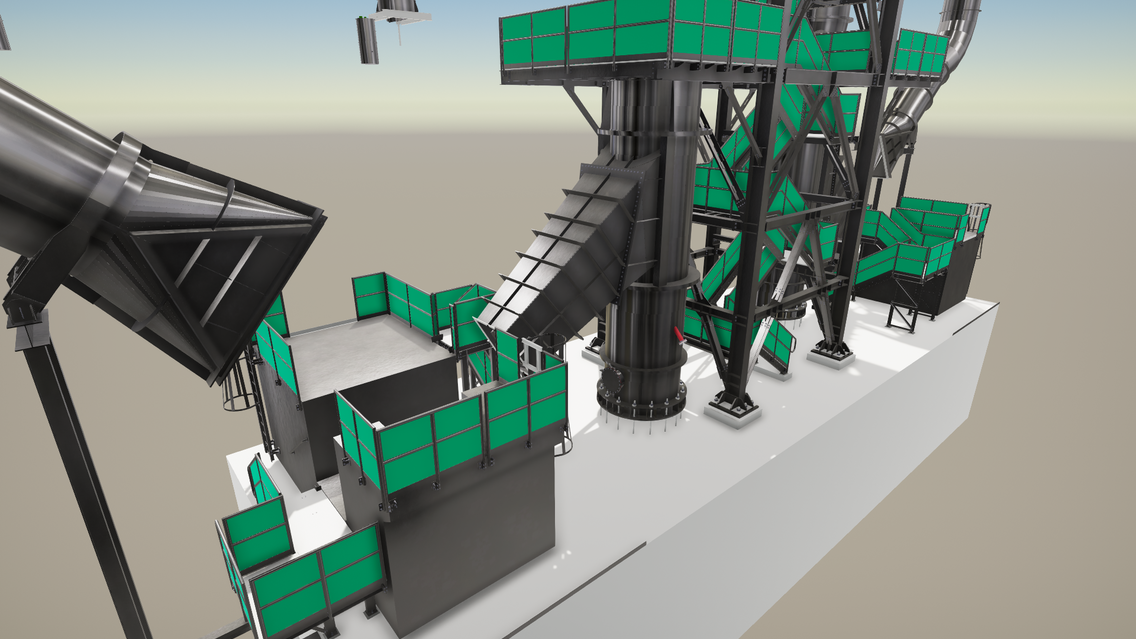

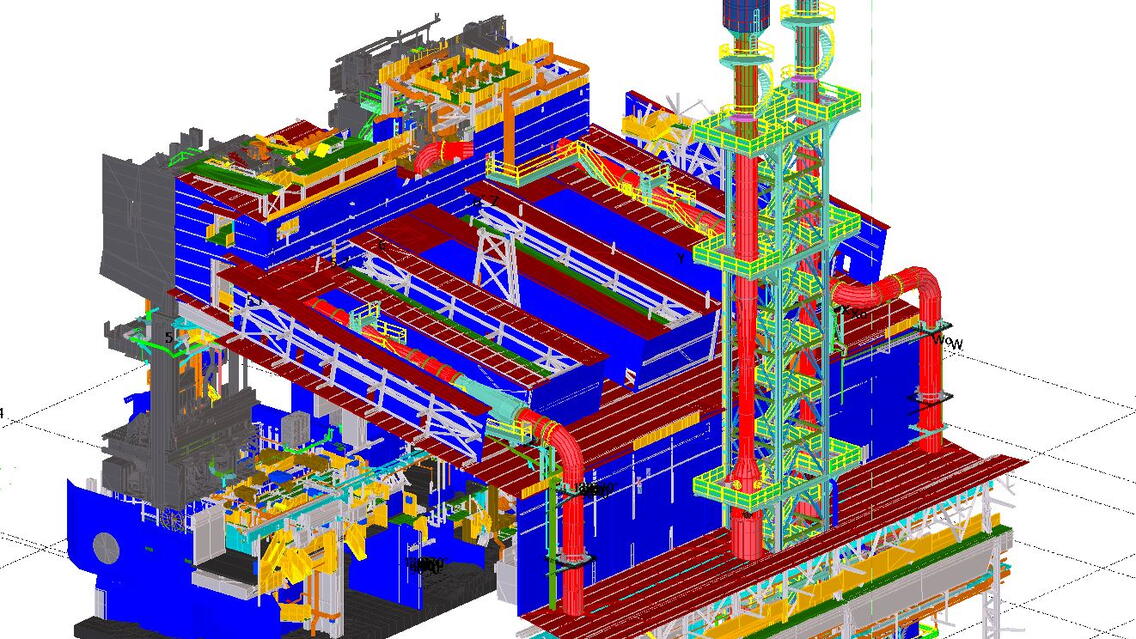

The final workshop documentation was issued in parts. The structure is manufactured in Europe and shipped to Brazil in containers. Therefore, emphasis was placed on the maximum use of space in the shipping containers. More straightforward drawings of single items and assembly parts are thus balanced by more complex erection drawings.

Technical highlights:

- The top level of the stack is at a height of +71m

- The construction of the stair tower is 50m high and, at the same time, serves as a support for both flare stacks.

- The weight of the delivered structures was about 400 tons

- The total length of both Lines of the flue gas duct was approx. 200m

- The Trimble Connect program coordinated the partial Tekla models during the work.

- The design temperature of the flue gas duct at the entrance to the Combined Tower was 1200°C. This is where the temperature drops. The other structures were designed for 300°.

- At the outlet of the flue gas duct at the location of the Flare Head, any harmful substances are burned with the help of three burners. The structure of the stack and flare head was designed for 400°C