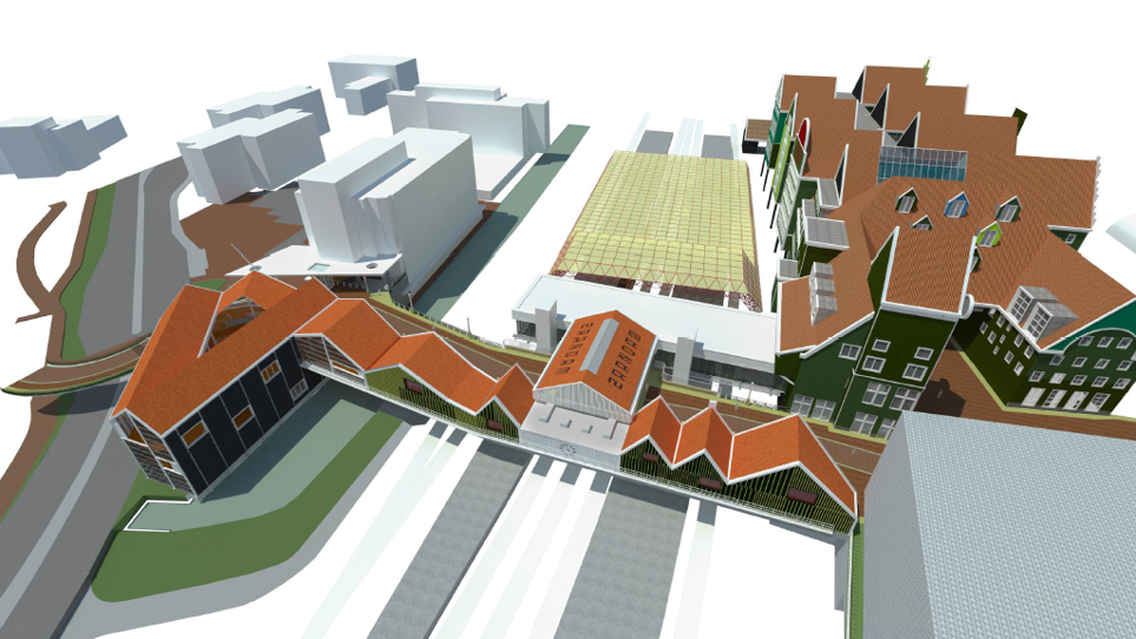

Continuous connection between the west and east side of the track

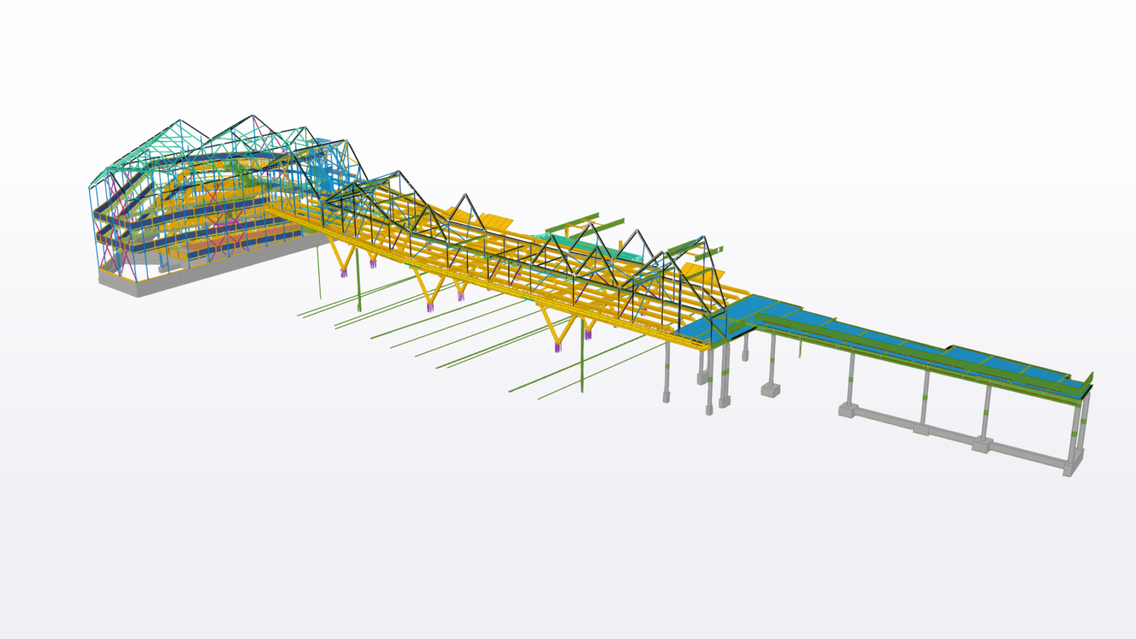

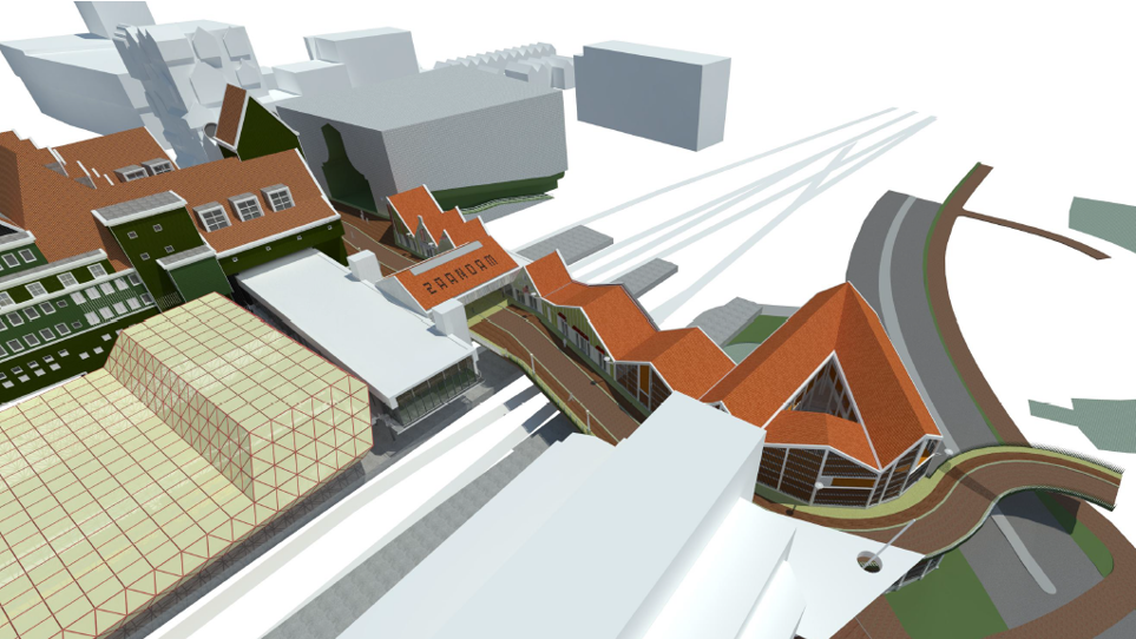

Hegeman Bouw & Infra has been commissioned by the municipality of Zaanstad with the realization of the project ‘Spooroverbouwing Zaandam’ which also provides for cyclists and pedestrians a continuous connection between the west and east side of the track and offers access to the existing drive. This project is a combination of construction and civil engineering and consists of the following parts:

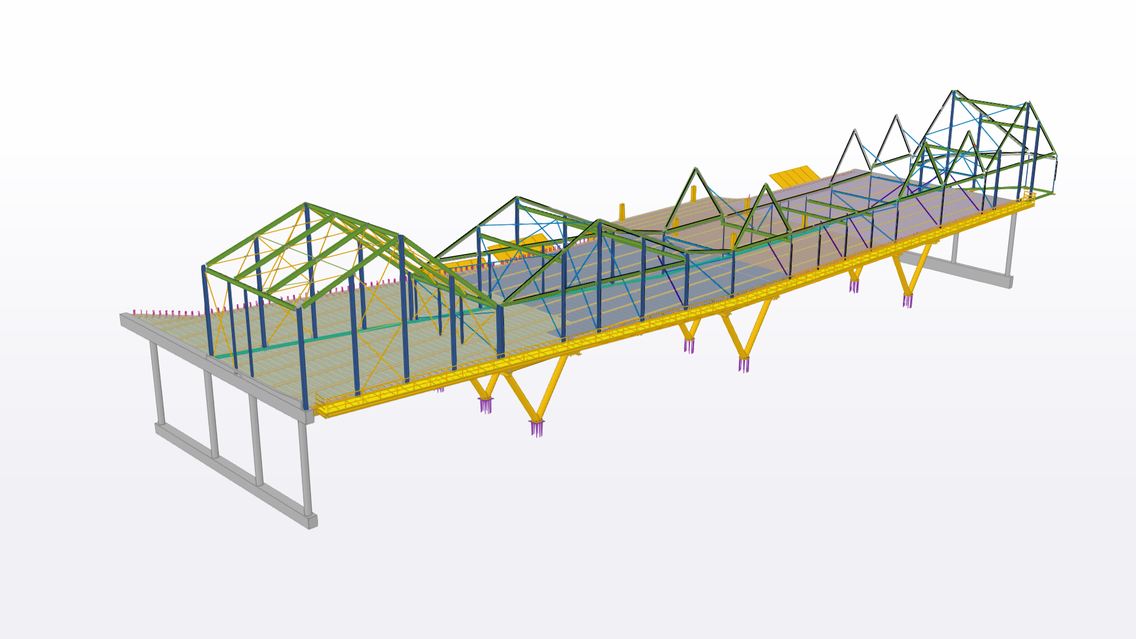

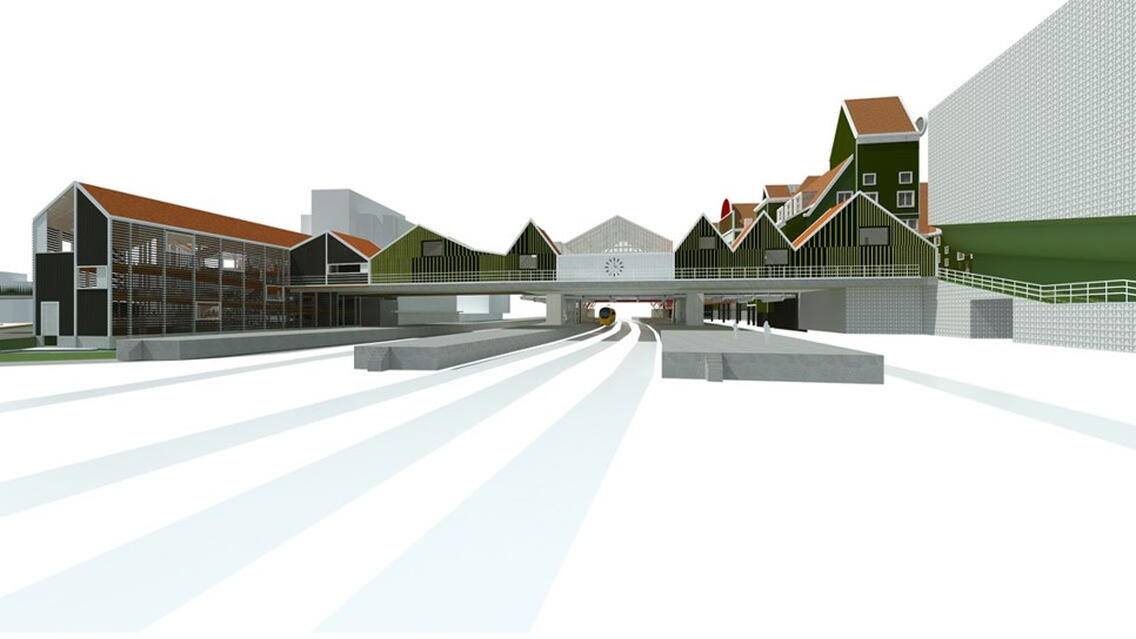

- Part 1 Spooroverbouwing: Combined steel and concrete construction with bridging over existing tracks and platforms. This building is equipped with authentic shops and has a bicycle and footpath.

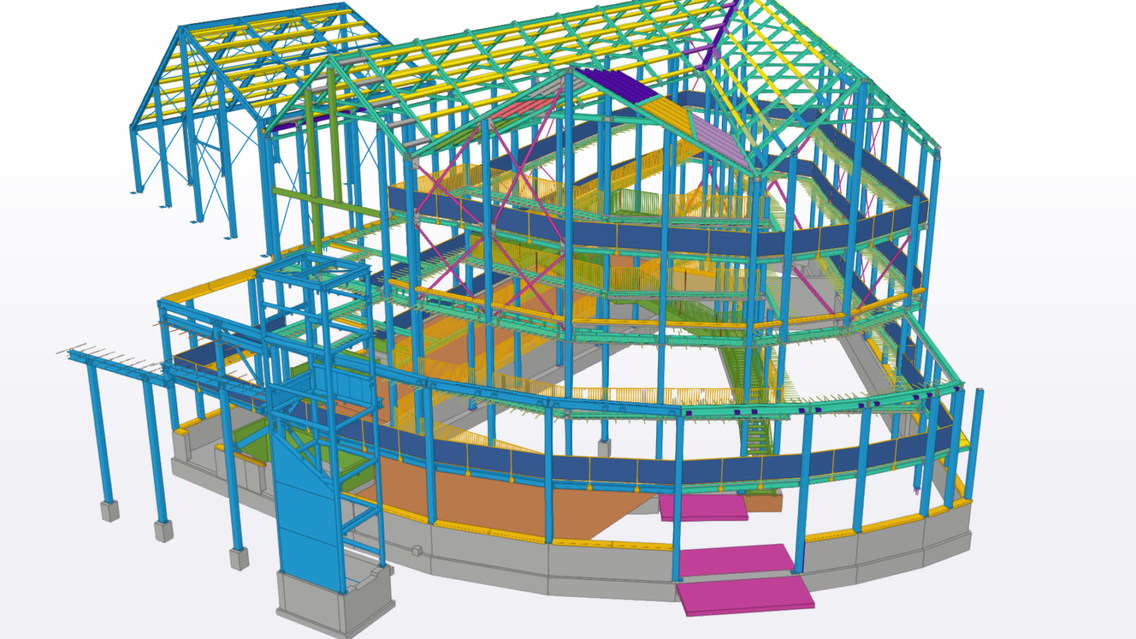

- Part 2 bicycle storage (dry barn): Steel construction with 3 levels of floors by means of hollow core slabs which are carried out as ramps.

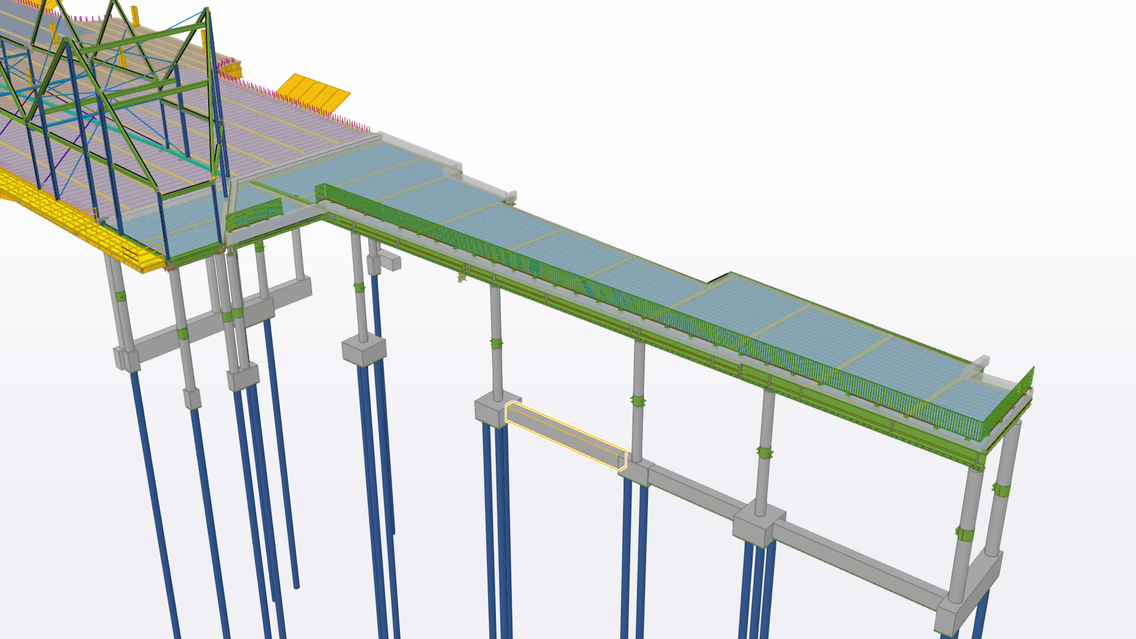

- Part 3 Dekaansluiting to the city centre: Connection deck between track rebuilding and town hall square carried out in a steel slab concrete floor and a concrete base.

In the project ‘Spooroverbouwing Zaandam’, BIM, when it comes to building information management, comes to its right. In view of the nature, complexity and level of the project, we have several disciplines involved during the design phase. In order to ensure that the right information comes to the right person and that the various designs are aligned, an intensive collaboration with the parties was appointed in the image. In particular, Buiting Machinebouw en Staalconstructie and architectural office NUNC Architects have played a major role in this.

Aspects in which BIM has come into its own for this project

- Applying the 3D scan for the integration of the 3 project components into the existing situation

- Coordination between steel construction and architectural components

- Resolve conflicts between the designs of the various parties

- Conflicts of designs carried out by third parties

This collaboration goes beyond the design stage because the wooden purlins modeled with Tekla Structures are read by Jongeneel (wood trading company) as an ifc file and sent to their CNC machine where they can be produced directly. So this part of the process has gone completely paperless and saves weeks of repetitive work. Also Buiting machinebouw en staalconstructie uses the model for generating production drawings and NC-Files.