The chemical company Kuraray planned to increase its production capacity for polyvinyl alcohol at the Hoechst Industrial Park in Frankfurt, Germany from 70.000 to 94.000 tons per year. With the help of Tekla BIM software the project partners successfully planned and constructed a new production line which will significantly increase the plants energy efficiency.

Smooth cooperation

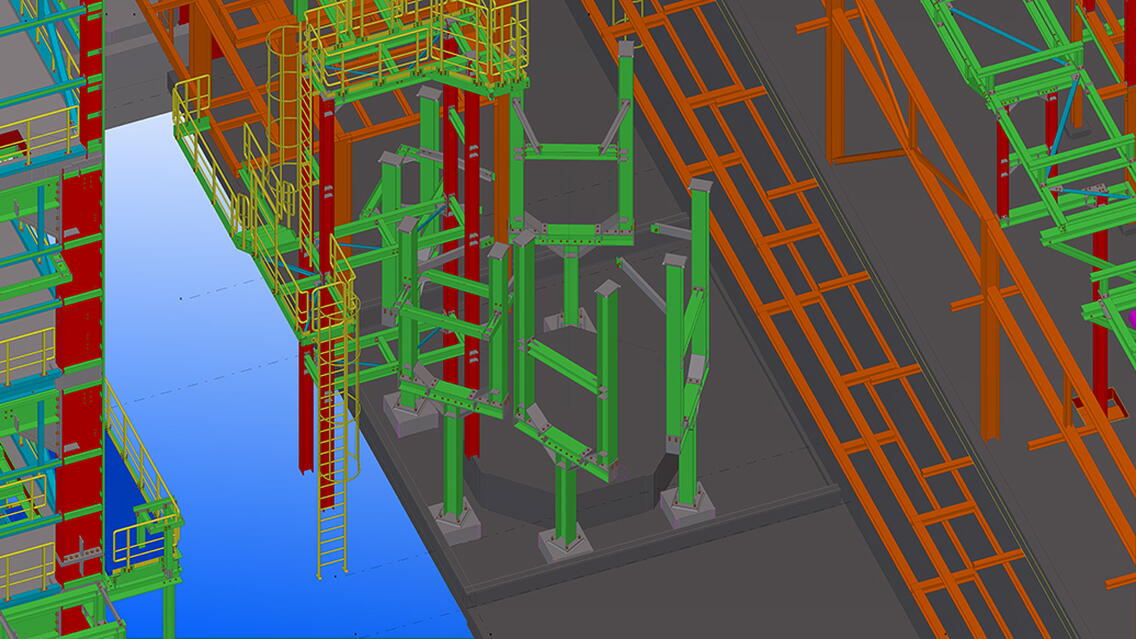

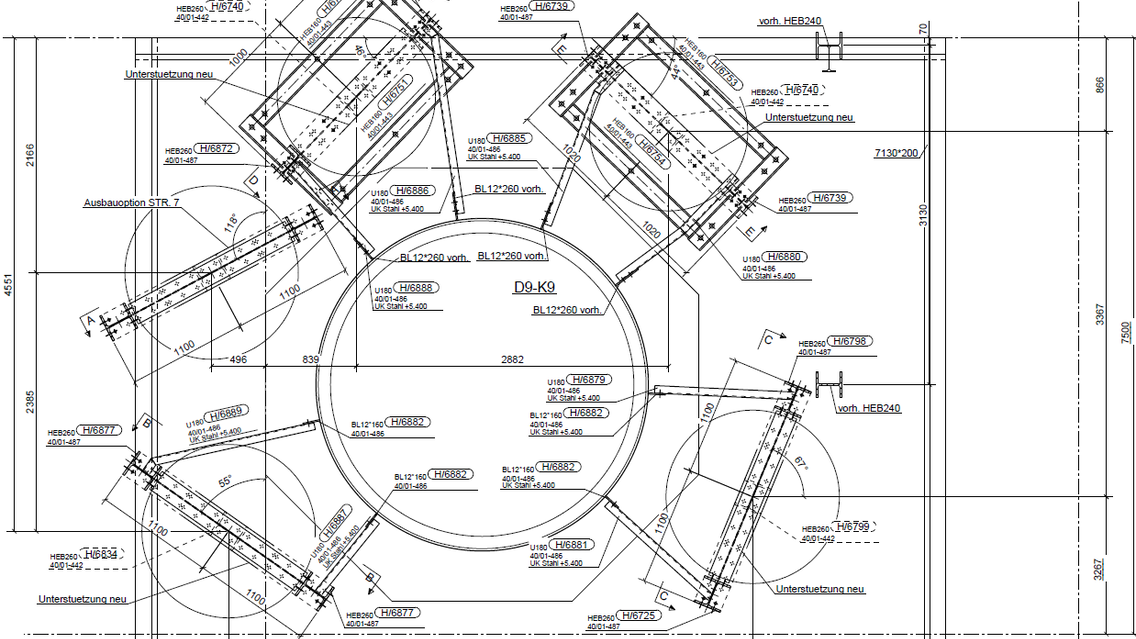

Tekla customer Voss & Kamb und Partner was responsible for steel and cladding, including structural analysis and detailed design and erection planning. The team worked on the project for more than two years with up to ten people, utilizing Tekla’s multi user mode. Apart from the designers working with Tekla, the structural engineers were provided with viewer licenses which enabled them to constantly access the current status of the model.

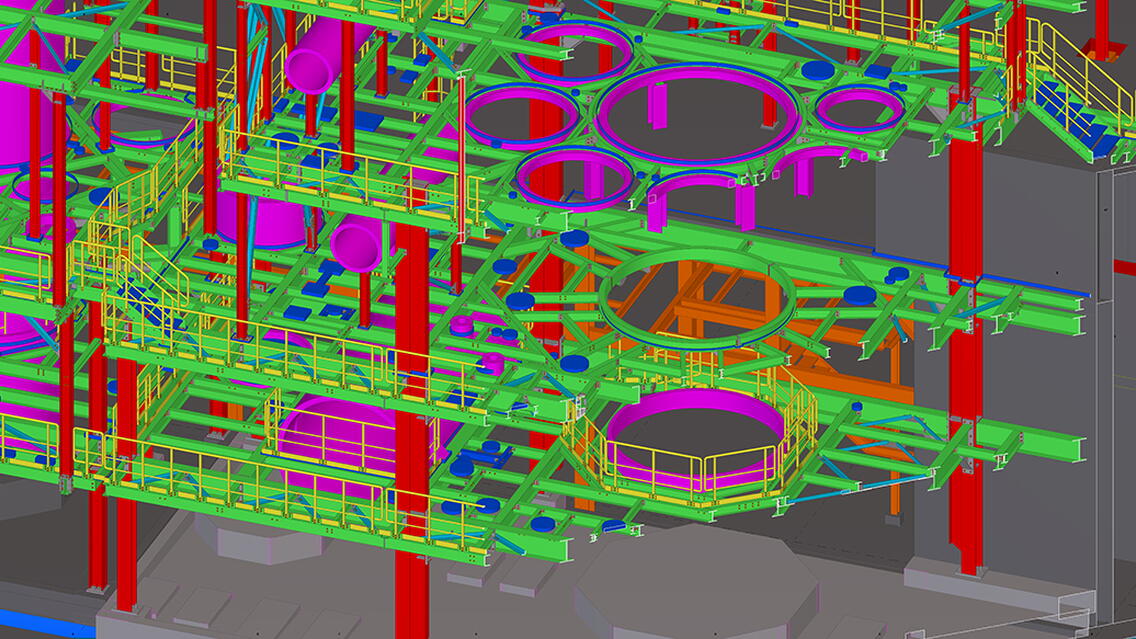

To ensure smooth cooperation with the plant design conducted in AVEVA PDMS, the teams continuously exchanged up-to-date project information (via SDNF). Voss und Kamb created a macro which automated the exports of more than sixty individual files. PDMS-components were referenced in the Tekla model. The model of the initial design was also exported via IFC to Scia Engineer for the structural analysis. Additional project parties accessed the project information via 3D PDF.

BIM on site

The Team of Voss und Kamb was also responsible for the project’s construction management. On site, the construction supervisor was able to constantly access the model with a laptop, VPN and Tekla Viewer. The model was the center of the weekly team meetings and served as a reference for questions and discussions – including, erection planning, quantity take-offs and identification of clashes.

The model also played an important role in coordinating the plant extension with the existing facilities. The team used a Faro laser scanner to scan the existing plant. The point cloud was then imported to Tekla and compared to the Tekla model.