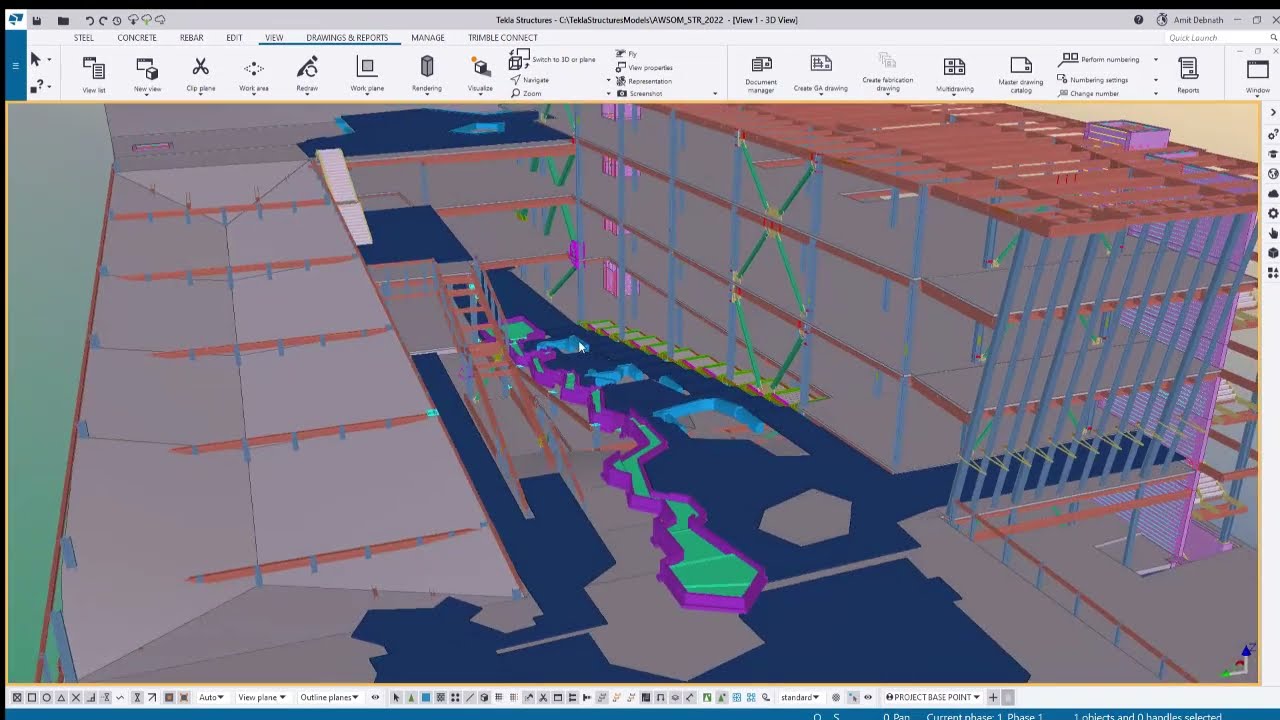

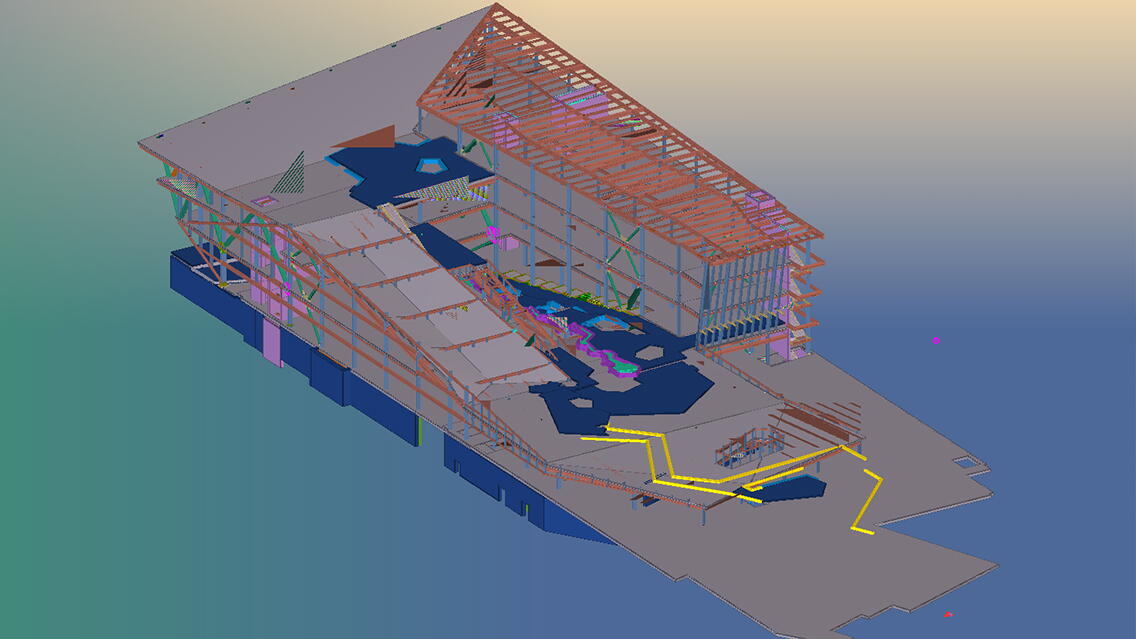

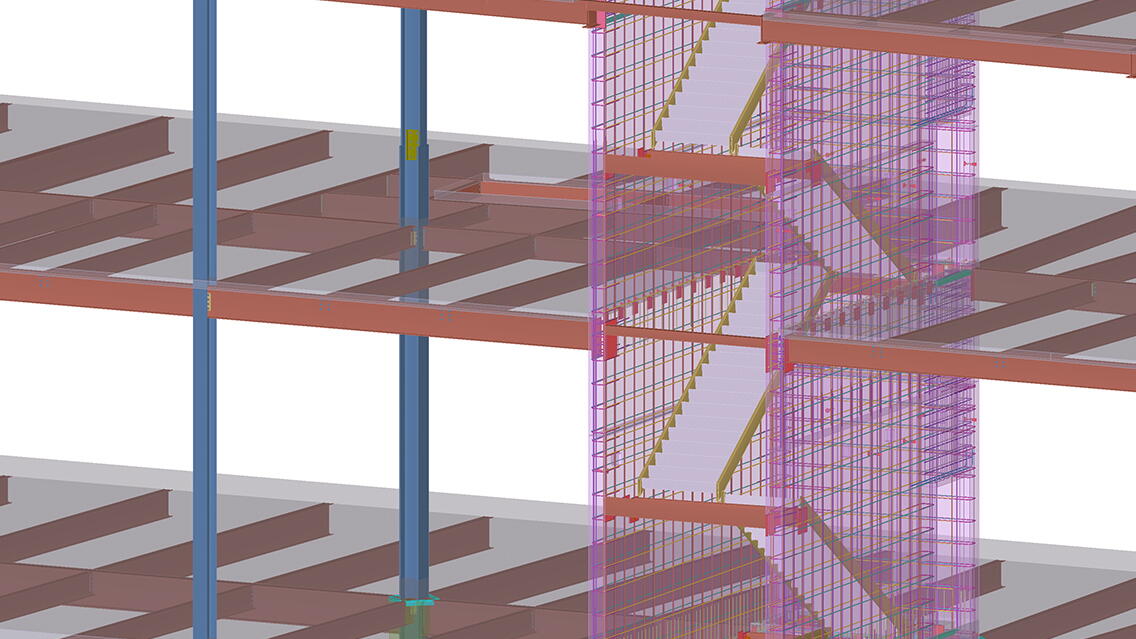

Alice L. Walton School of Medicine is a national, state-of-the-art medical facility located in Bentonville, Arkansas, aimed at a 2025 inauguration. This 6-storey educational building will have the leading medical and scientific minds as faculty to help students rise to the health challenges of the 21st century with a focus on physical, mental, emotional, and social health. The building's total height is 170’-0” with complex geometry with a green roof and runnel on the top with different items on the roof.

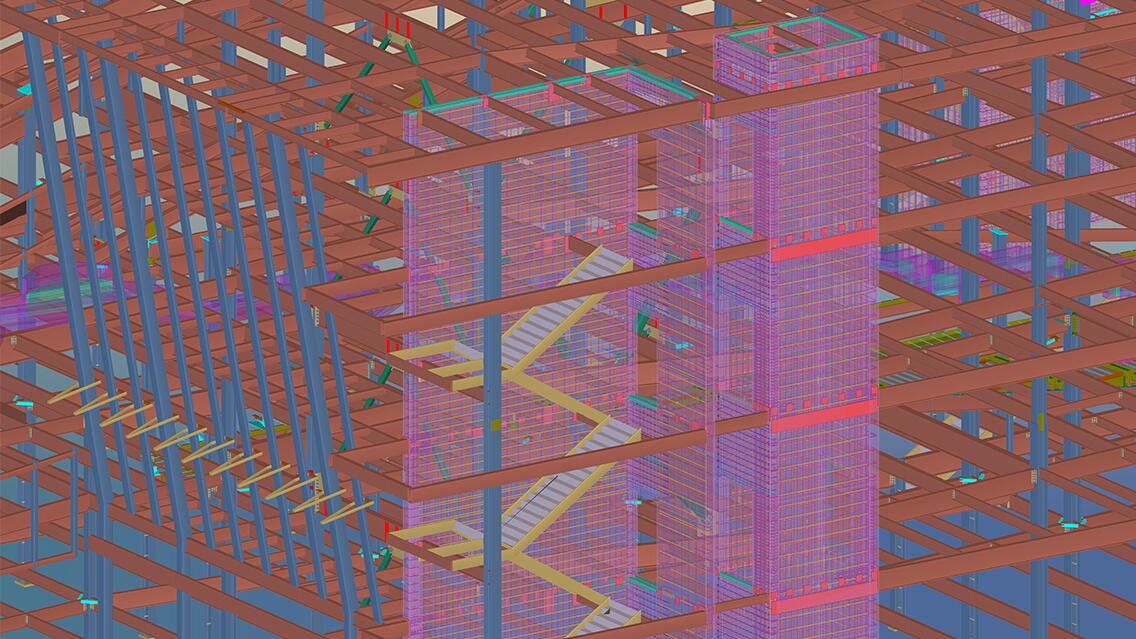

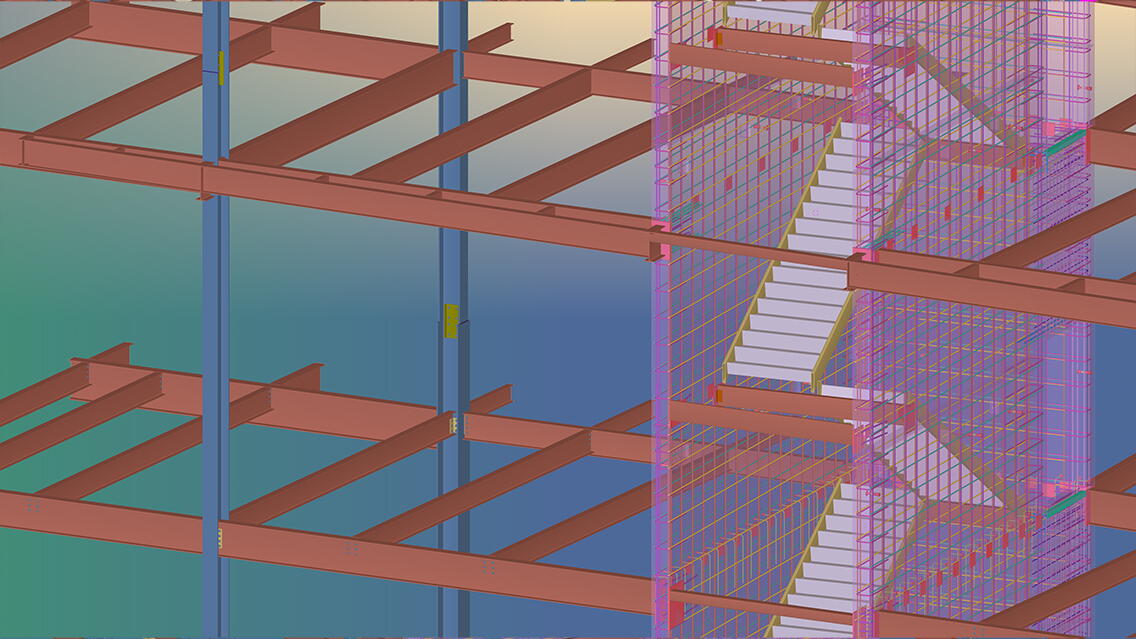

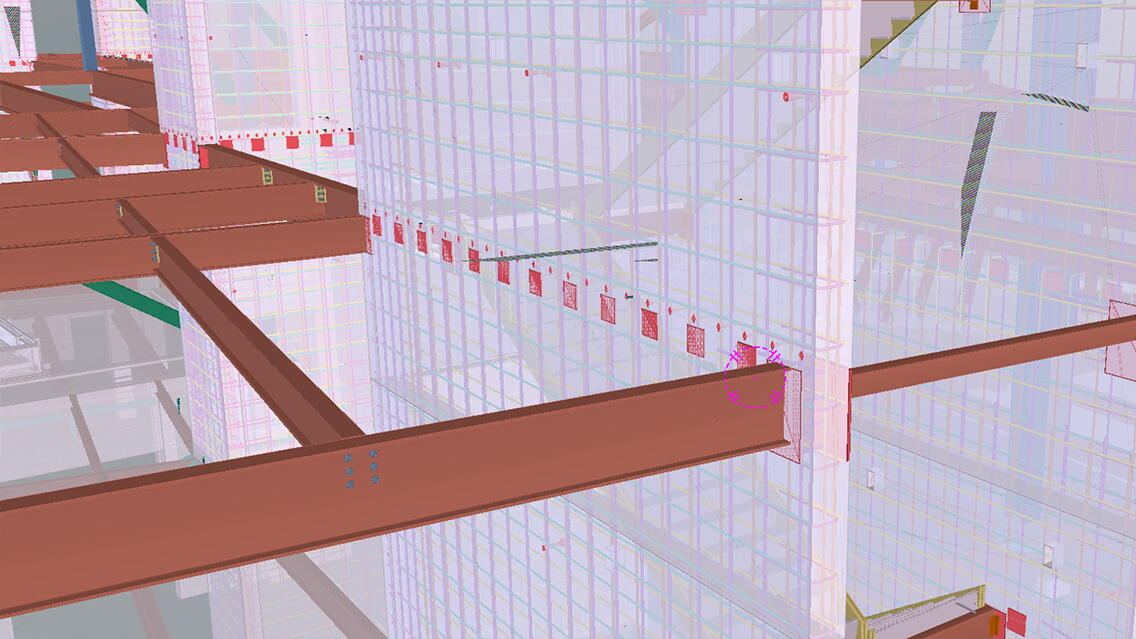

The scope of work included concrete 3D model creation, constructability review, concrete lift drawing creation for all the core areas, rebar modelling, formworks anchors, embeds, Hilti rail model and drawing, pockets placed into the core wall and drawing creation and coordination with other elements, coordination with bent plate, steel connection, steel beam, and steel stair for embed connection and clash check with the steel model.

Challenges

- Owing to a large area, the project delivery team faced several issues that were tough to resolve within the stipulated period. In addition, there were multiple submissions for different buildings on the same date.

- The shop drawing standard was difficult, compared to the client’s requirement (during project onset).

- More than 47 types of embeds were used and overall, 1500 embeds have been placed in this project. Moreover, formwork anchors, form savers, Hilti rail modelling, and shop drawings were also done.

- Metal decks were used in this building. The deck was laid out as per the structural and architectural drawing also by coordinating with bent plates, and steel beams. The team also provided the block out for braces and steel columns that pass through the floor. In addition to this, the team also coordinated embeds for other subcontractors.

- There were several items for structural elements like steel beams, stairs, metal deck, sloped deck, topping slab and ramps, runnel, and various curbs on the green roof. Elevations were different and tough to adjust throughout the floor. In addition, structural slab were with different point slopes.

Benefits of using Tekla

- Tekla Warehouse helps to create embeds, anchors, and Hilti rail as well as some custom components.

- The team had linked other subcontractors' models into their model and done all the coordination.