Project Title: Liwa Plastics

Site Address: Oman

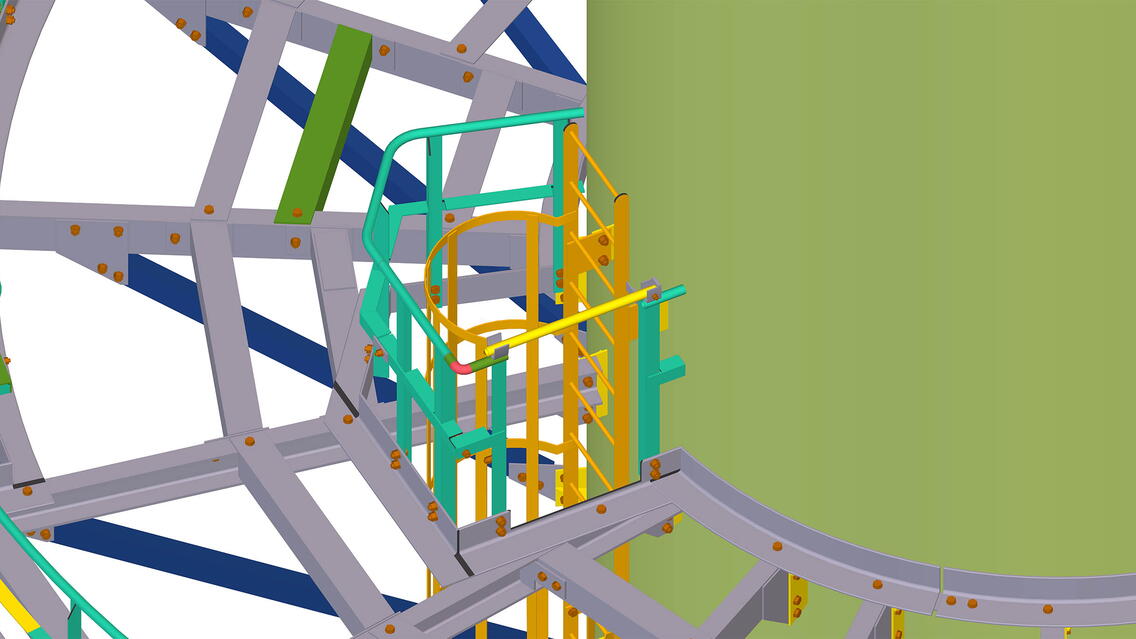

Structure: Structural Steel for Ladder and Platforms

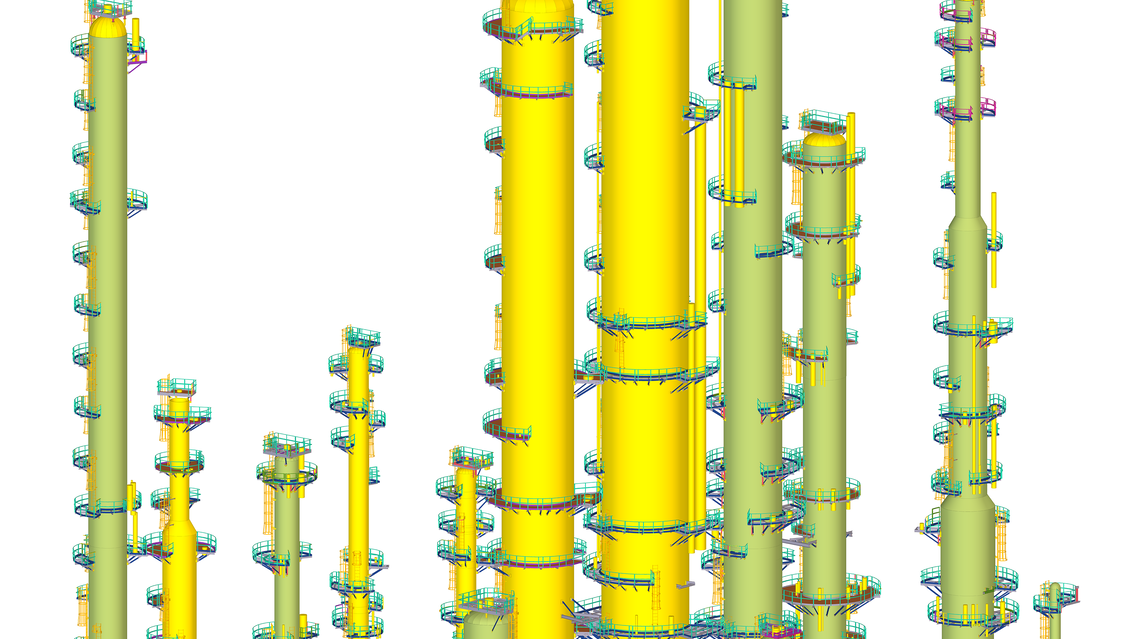

The Sohar refinery’s improvement project is designed primarily to improve the Sohar refinery’s ability to overcome existing technical constraints associated with processing the changing quality of Oman Export Blend (OEB) crude. Sohar refinery’s improvement project will also enable the refinery to meet international environmental standards, serve growing domestic demand for refined products, and enhance the refinery’s competitiveness and profitability.

In addition to the revamp of an existing residue fluidized catalytic cracker, Sohar refinery’s improvement project involved installation of five new units at the refinery, including an 82,000-b/d crude distillation unit, vacuum distillation unit, delayed coker, hydrocracker, and bitumen-blowing unit.

Upon reaching full commercial operation, the newly expanded Sohar refinery will be equipped to process 198,000 b/d of crude into more than 13 million type of finished products.

Our scope of detailing consisted of structures of approximately 800 tonnes of structural steel work plus ladders, gratings and handrails.

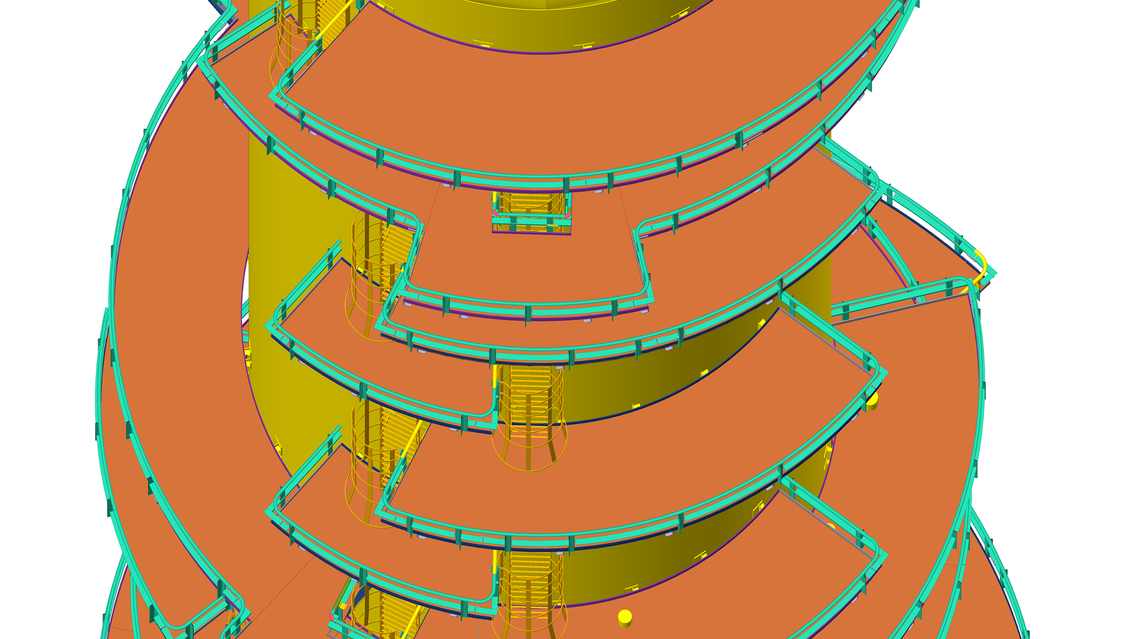

46 vertical circular platform were detailed as per part of this project with 630 Tons.

The complexity of this project was modeling and the detailing of the curved members. The circular platform had to be spliced to accommodate the maximum transportation criteria. Curved handrail modeling and detailing was also a challenging task.

To avoid mistakes in the dimensions picked in Tekla Structure, an internal excel worksheet was created to ensure that the calculated dimensions would match with the picked dimensions in Tekla Structure.