Project Brief:

Tamilnadu Cements Corporation Limited (TANCEM), a wholly owned Government of Tamilnadu undertaking, started business from 1st April 1976, set up cement plant at Ariyalur in the year 1979 for cement production. TANCEM planned to expand its business and built 3000TPD (Tonnes per Day) Clinkerisation plant at Ariyalur, Tamilnadu. Objective of Government to expand production of Cement at this plant is to help lower and middle income groups (LIG, MIG) to purchase cement at subsidized prices.

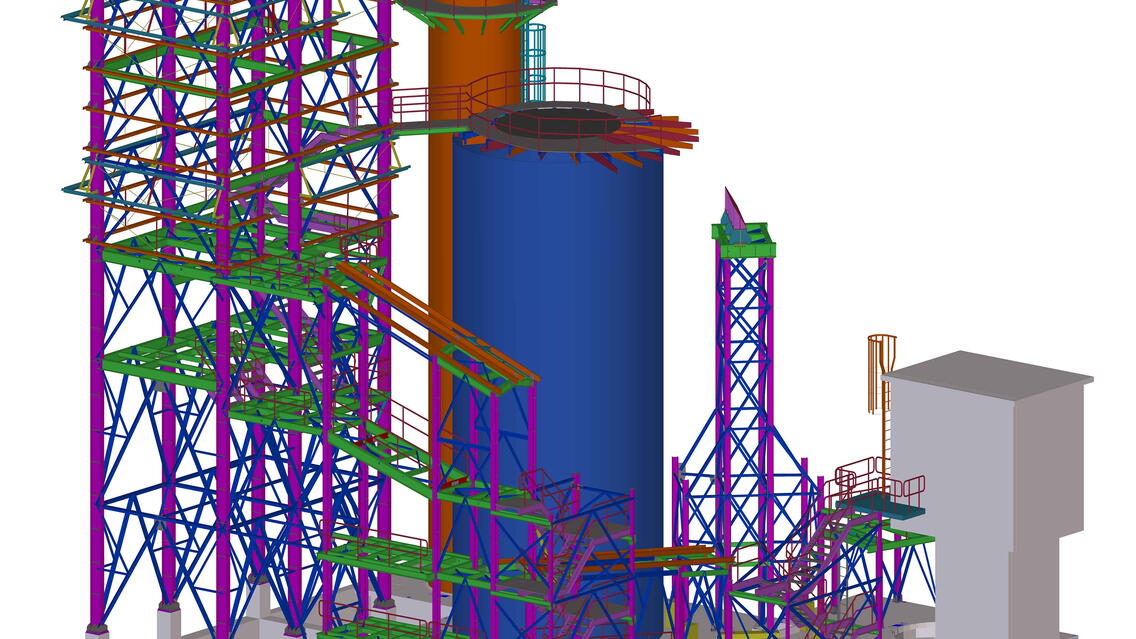

Details of Preheater Building:

Preheater Building is one of the most vital parts of a cement plant where the raw meal is preheated using outlet hot gases of the kiln. 5-stage single string in-line calciner system is used for this purpose. Each stage of Preheater consists of fabricated cyclones and connecting gas riser ducts. Cyclone and riser ducts are specially shaped to have smoother flow, good collection efficiency with lesser pressure drop. The calcined material from preheater is then fed to kiln where it is further calcined and sintered.

Preheater Building has a plan size of 19.4m x 18.2m and an overall height of 117m with a built up area of 2705sqm.

Building consists of RCC super structure of seven floor levels (+8.850, +19.250, +36.250, +51.250, +68.450, +81.850, +93.650) with 58 nos. of intermediate structural steel platforms and access stairs at multiple levels for maintenance and regular monitoring of preheating the raw meal. Bucket elevator steel sheds are mounted on cantilever RCC beams, the top most level of bucket elevator shed being +117.00m.

Benefits of Tekla BIM Software in the project:

1. Facility to import STAAD model into TEKLA, which reduced considerable time involved in modeling

2. Better visualization and understanding of structure and interference elements in 3D for designers and BIM modelers

3. Making effective structural configuration/ arrangement with different options with due consideration for erection feasibility

4. Produces clash-free and error-free detailing / quality drawings, which eliminates problems and reworks at site

5. Interoperability with REVIT structure, which produces combined RCC and steel model

6. Sharing of model with site engineer with TEKLA BIMsight viewer helps for better understanding of structure and execution

7. Co-ordination with other BIM softwares using TEKLA BIMsight

8. Readily generatable BOQ itemwise

9. Multiple team participation / deployment possible for drawing production

10. Easy tracking of new changes / revisions

11. Able to take section wherever required at any point of time

12. Linking of reference 2D (AutoCAD, PDF) drawings into model

13. Can generate sequence / animation for effective presentation

14. Can link with time schedule and costing