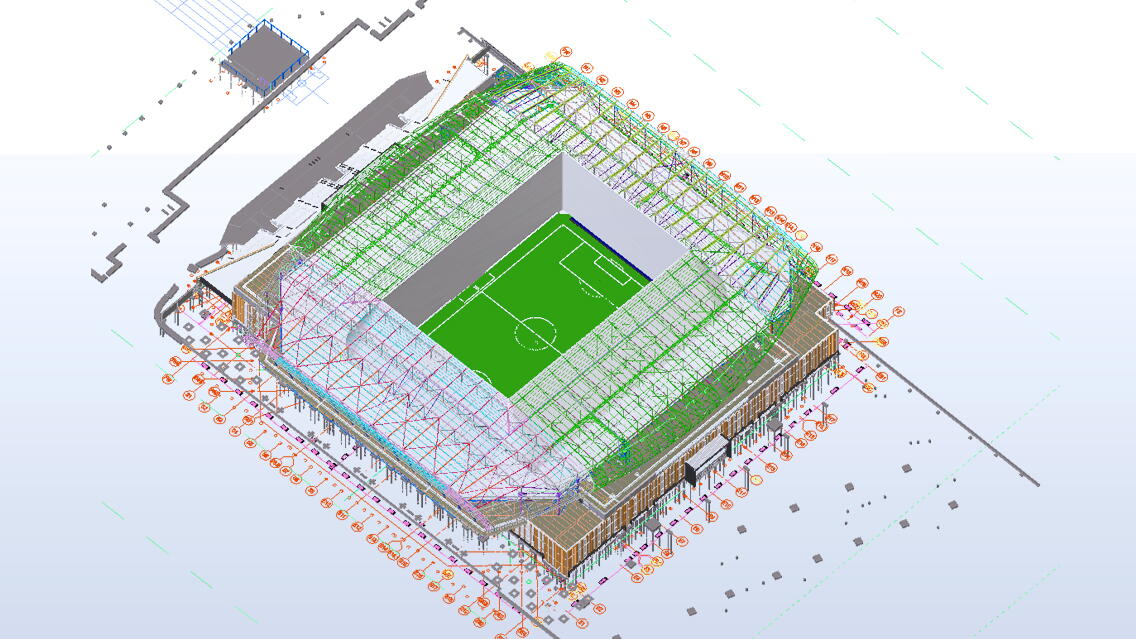

The football-first sporting arena boasts a capacity of 52,888 seats and an eye-catching design that brilliantly blends the modern with the traditional. This will serve as the next home for Everton Football Club and is one of the most eagerly anticipated stadium development projects on the planet.

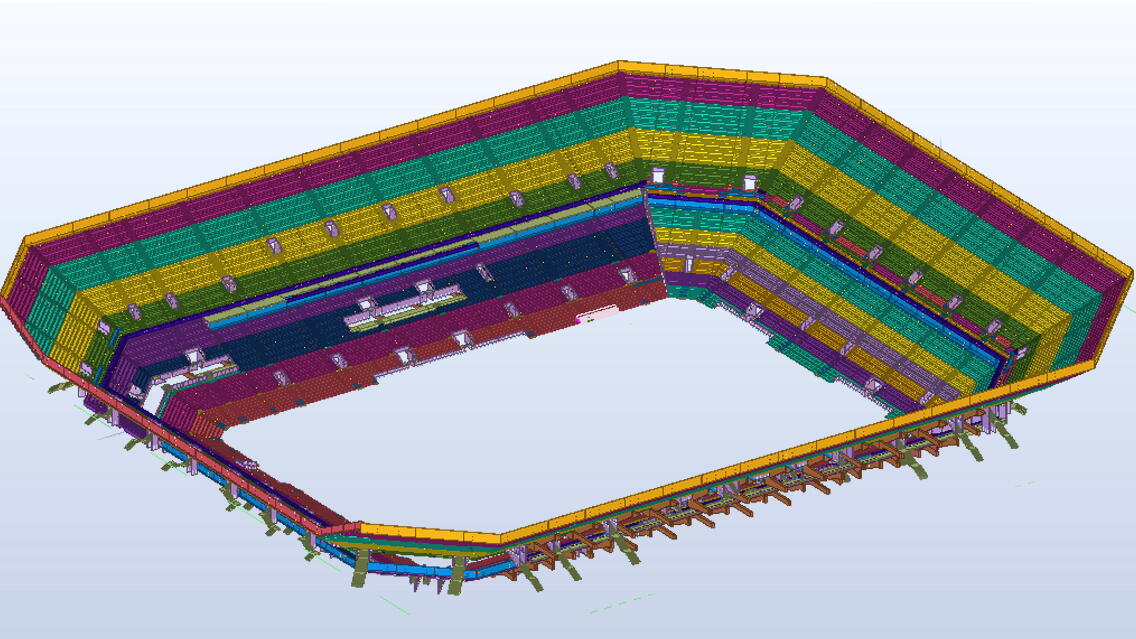

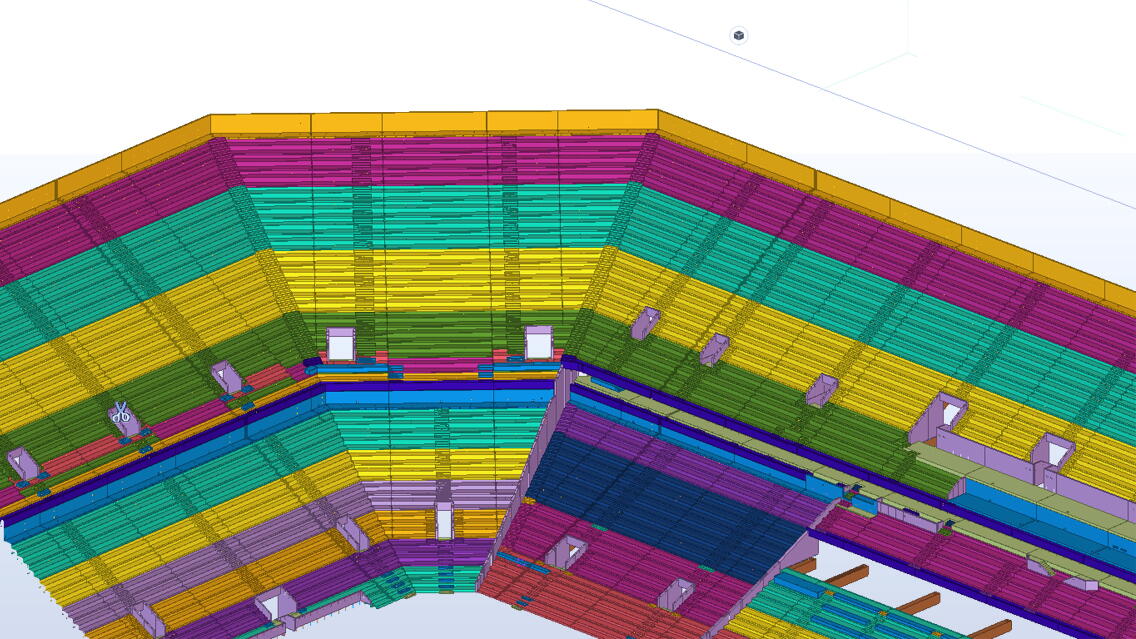

Telge Projects scope of work included different precast elements such as wall panels with different shapes i.e., L walls and Parapet walls. There were different L walls on the North Upper and Lower stands as well as the South Upper and Lower stands.

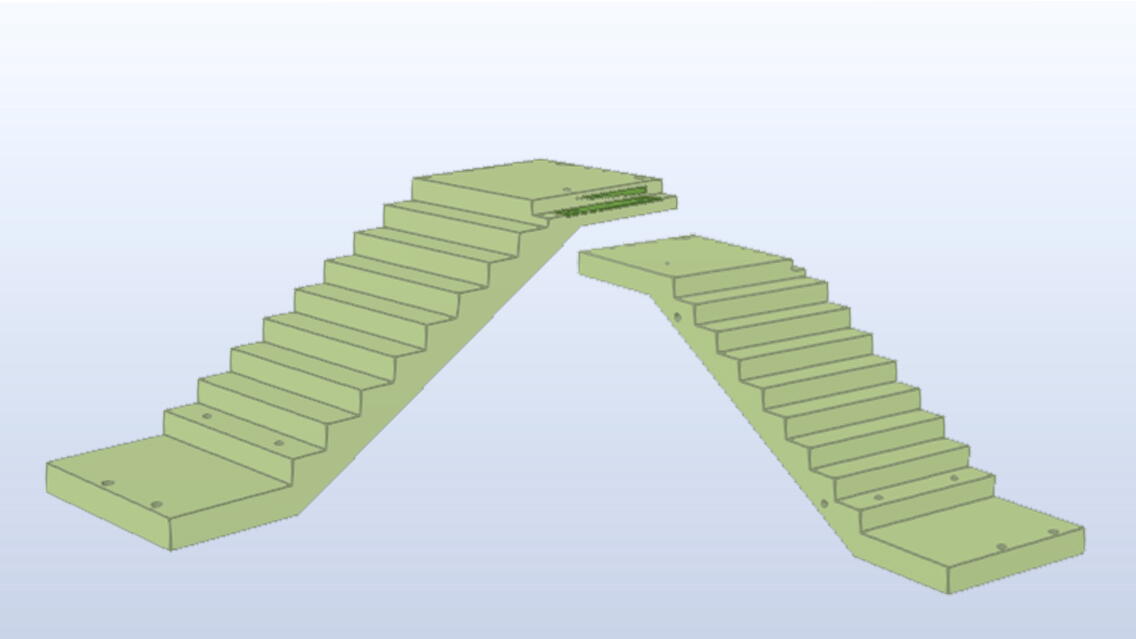

The scope also included modelling 140 stairs as well as rebar modelling of some of the stairs. These stairs had some critical invisible connections at end supports.

Challenges

Given the nature and massive size of this stadium, the volume of work was huge and the accuracy needed at each step was even greater. The project was highly complex and had very tight deadlines to add to the challenges.

- The number of stakeholders involved in a project mandated close coordination and seamless collaboration to avoid clashes as well as timely delivery of the project time without any budget overruns

- There were very large number and a wide variety of units included in the project

- The stairs had some critical connections and it was difficult to place a rebar at the connection area without clashing

- Some stairs had difficult geometries at connection areas and it was not possible to maintain the shape codes as given in the inputs

- The rebar modelling at connection areas was one of the most challenging parts

- The parapet was of a very unique shape due to which different shape codes had to be used

The benefits of using BIM and Tekla Structures

3D Visualization: The stadium structure was very unique given the complexity of the design, the absolute size, and the number of different units involved. Tekla’s constructible 3D model was the only way to clearly and accurately visualize the structure, and this helped the team members to understand the units or geometry properly

Time & Effort Savings with Cloning: One of the most crucial tasks in any project is to deliver the project on time, Tekla helped ensure this! There were a huge number of elements that needed to be delivered in very short timelines and this included a number of repetitive elements. With Tekla, the team was able to cover a huge quantum of work much faster by utilizing the powerful cloning feature for different inserts, rebars, and other elements.

Automated, Updated & Hyper Accurate Drawings: Due to the realistic and accurate information filled inside the 3D model, it was easy to extract all the drawings readily from the model.

Truly Seamless Collaboration: With a project of this stature, there will always be a large number of stakeholders and several team members working together to ensure timely completion. This makes collaboration an extremely critical component of the project delivery to avoid clashes with different disciplines or even within each team.