Project Overview:

Hinkley Point C is the first nuclear power plant to be built in the UK in last 20 years. The power plant is equipped with two new nuclear reactors capable of generating 3.2GW of energy. The site is located at Somerset coast and once commissioned, it will cater to 7% of UK’s power need. NNB GenCo (Nuclear New Build Generation Company) are the project owners; CNEPE (National Centre for Electricity Generation Equipment) constitute designing firm reporting to NNB GenCo. Atkins is level 3 designer working in collaboration with BYLOR (Bouygues and Laing O’Rourke-Contractor Joint Venture), the civil works contractor.

Atkins' involvement:

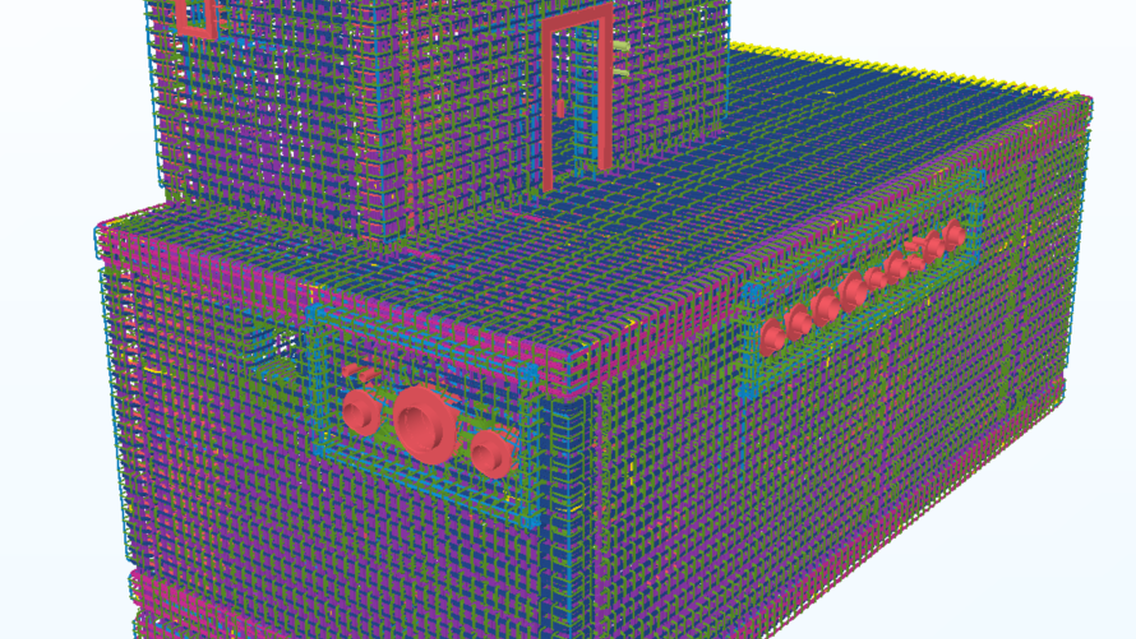

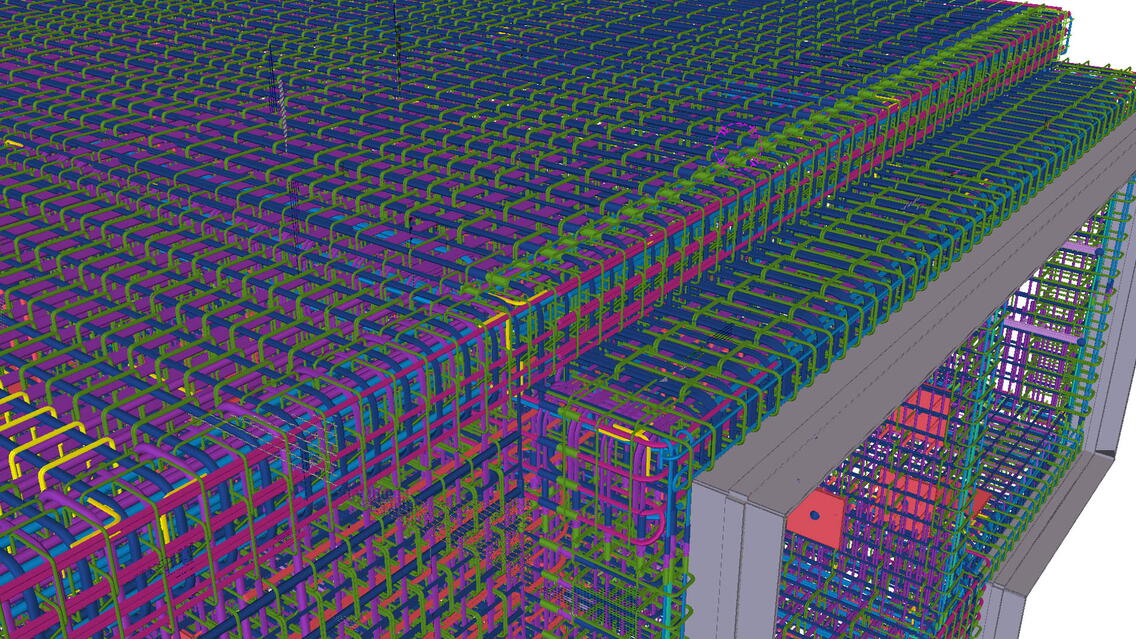

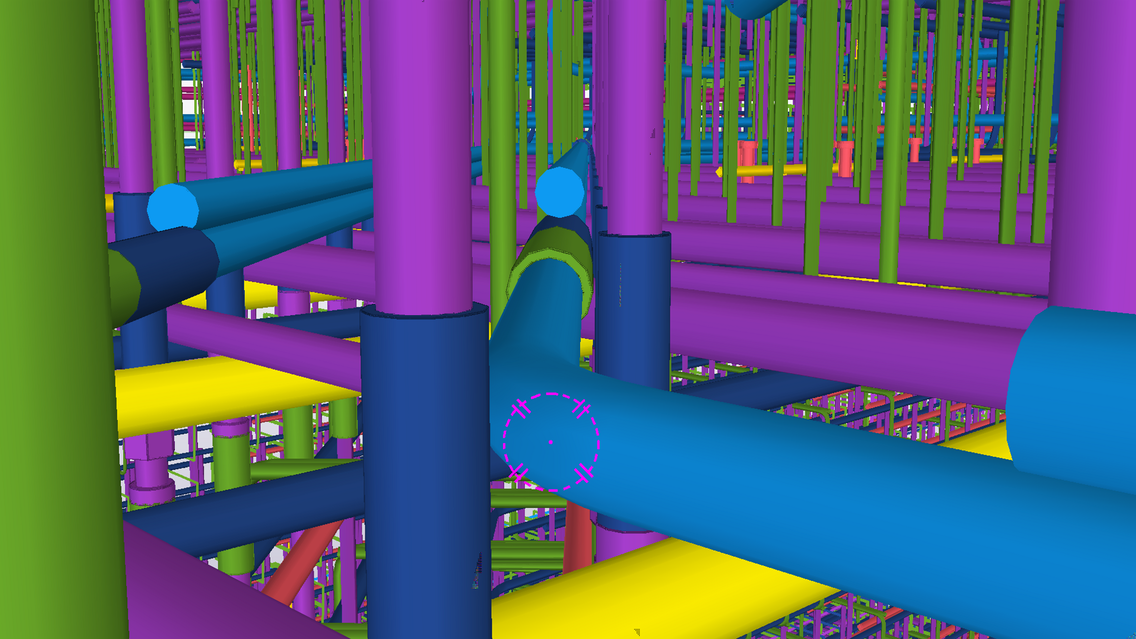

Atkins has been awarded by CNEPE to deliver detailed design of Technical Galleries (underground tunnels), Classified Building and Unclassified Buildings. Atkins is delivering detailed design through modelling solutions integrated with expertise in 3D RC services through Tekla Structures. Atkins follow the requirements of Good Practise Seismic Detailing Rules and, ensure that the models produced are not only compliant with respect to reinforcement design and arrangement but also highly buildable and allow efficient assembly by the contractor to achieve immense cost savings for the client. These 3D clash free models delivered are the digital representation of the designs and are virtually built prior to construction at site to derisk the construction processes.

In-house automation team has been playing a key role in HPC delivery mechanism whether it be via interoperability, information sharing or using automated processes to improve our efficiencies. The automation team has tailored Tekla APIs according to project need to automate robotic processes in both modelling and drawing processes. Atkins is optimising design of structural elements leading to cost efficient design through automation and innovation.

Atkins solutions and added value through Tekla:

- Seamless co-ordination amongst modelling and checking teams effected through BIMsight via single project data file for a model

- Use of multi-user mode to enhance the pace of delivery of models and drawings

- Repetitive modelling practices have been identified and custom components have been developed by a team at Atkins to avoid the time spent in repetitive actions

- Atkins has effectively used Tekla APIs for creating check tools for models and drawings. While working with Tekla APIs, Atkins has suggested modifications in drawing related methods to Trimble India (e.g. GetRelatedObjects, Zoom selected etc.) in existing Tekla APIs

- Development of inhouse check tools by automation team with help of Tekla APIs (e.g. Lap length checker, Drawing checker, Model Annotator, Spacing checker etc.) to enhance the efficiency and quality of delivery

Project Highlights:

- Mitigation of risks associated with reinforcement clashes, handling of prefabricated cages, use of roll mats, cover and spacing prior to construction

- Facilitation of early procurement of rebars, couplers and other construction materials

- Achieve substantial savings on account of minimisation of reinforcement wastages at the site through rebar optimisation and bar mark conformances

Atkins has successfully tried out paperless delivery through proof of concept and looking forward to implementing paperless construction through use of 3D models on site with the help of BYLOR through Tekla Field 3D to bring a step change in digital delivery.