Project Scope:

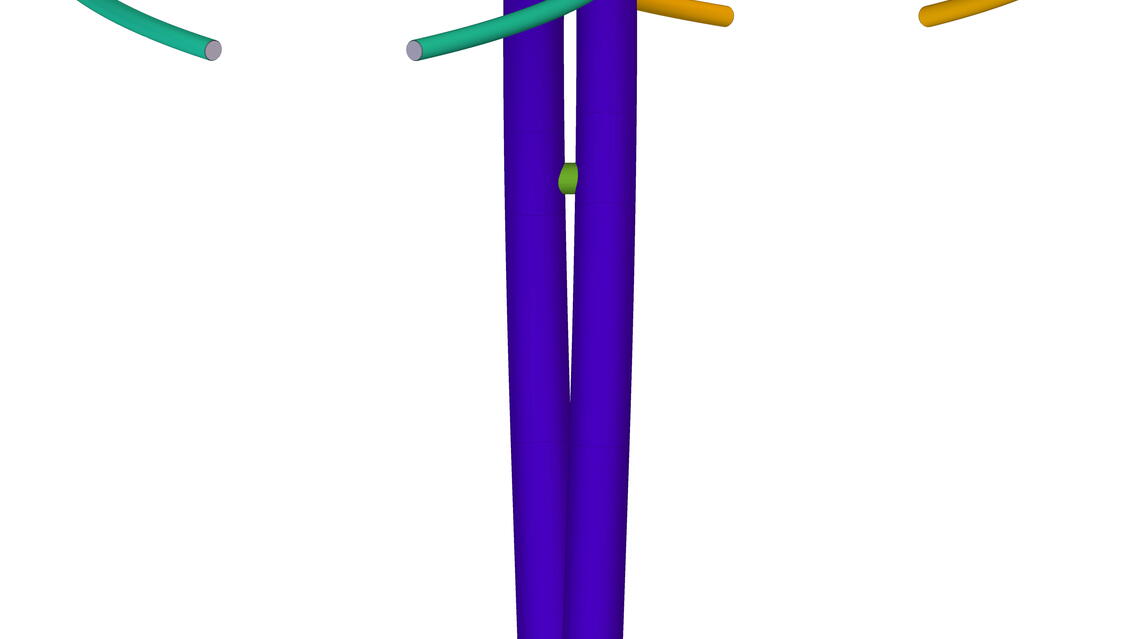

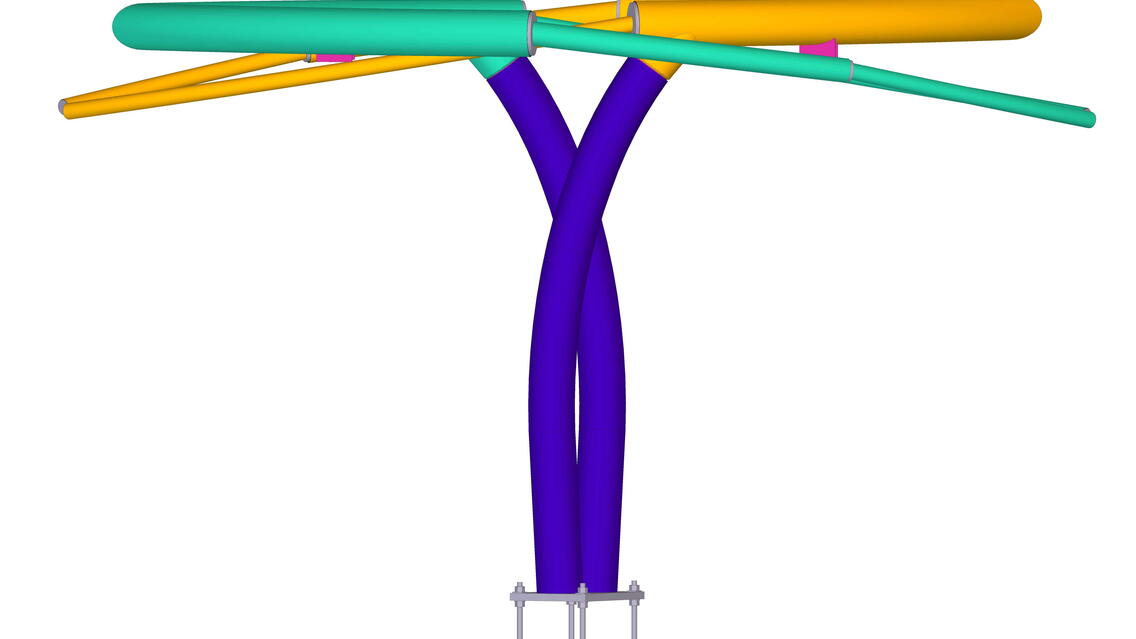

To make the structural skeletons for eight ornamental canopies for a casino at Mystic lake BLVD, Minnesota. This canopy structure contains three segments in a frame and the entire frame is field welded to the canopy columns.

Project Highlights & Challenges:

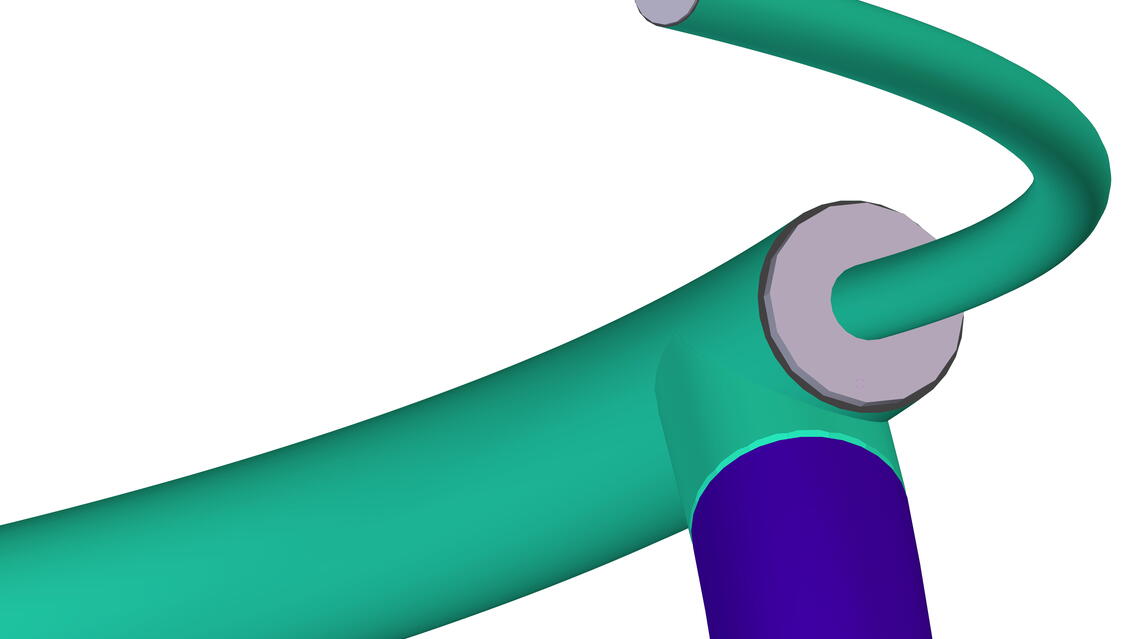

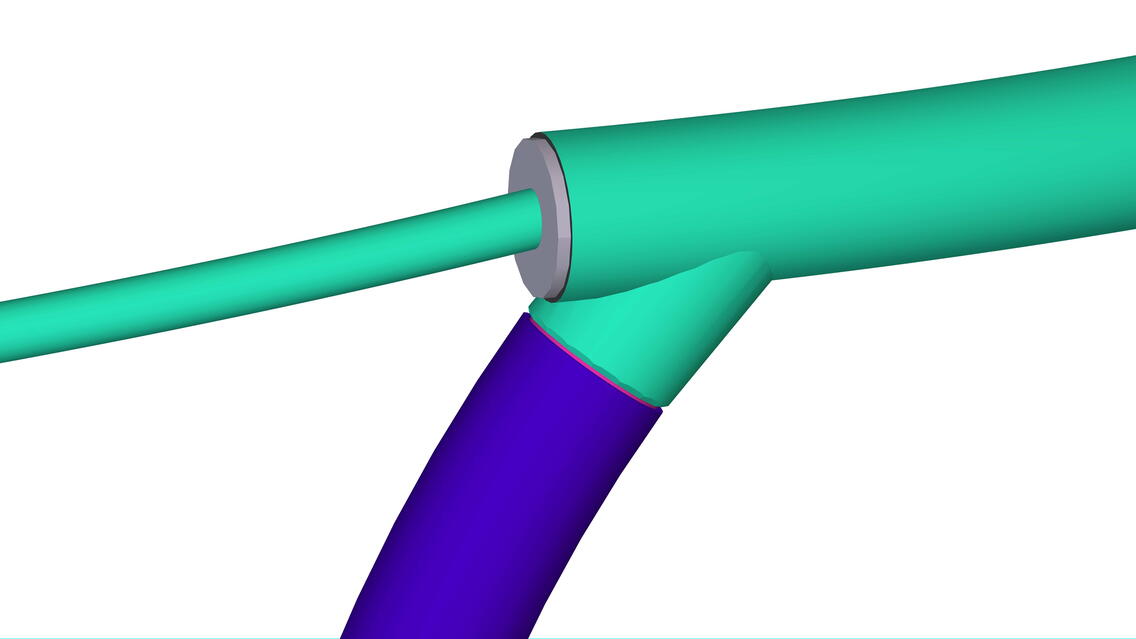

This is a small project compared to some other projects we have executed using Tekla Structures but this small project becomes a complex one because of the special architectural structure and shape required for the client. In this project, all structural members are pipe sections. The canopy frame is supported by two huge pipe columns which are connected with anchor rods. When we look into these columns, it is a curved from its bottom to top. Though it is easy to provide curves for members as required in Tekla, here the challenge was to provide the curve with multiple radii throughout its length. So we placed this column by using poly beam property and provided multiple radii to get a compound curved column. Next challenge was to rotate and cut the column to make this column as a twisted one. Once the columns are ready, additional stub provided between columns to get more stability. Now the columns are ready to bear the canopy frame.

Once columns are ready, we start placing the frame members. Here also each and every member has curves with varying elevations. Few pipes are tilted based on its own axis to achieve the architectural beauty we all want to see. Here we used multiple views, work plane settings and layout points to match each and every point as shown in the drawings. Here we provided the connection stubs to weld with the column and this small stub also needs to be curved to match the compound radii of below column. With the use of highly advanced and useful tools/options provided by Tekla, we made 3D model of this canopy with high accuracy.

Our last and final challenge was to prepare the Fabrication and Erection drawings with all required dimensions and details. Since the pipe sections bent with multiple radii, fabrication drawings become difficult to edit. At each and every point we needed to add additional dimensions over its basic dimensions. Pipe sections having tilt were too difficult to edit, and we used multiple views to show the rotation and tilt. Finally we come up with product what exactly our client was looking for.

At the beginning, we had apprehensions that this type of bending and rotations would be very difficult to execute, but we successfully completed this project by using only Tekla Structures and its amazing tools. Now we know Tekla Structures is capable to handle this type of challenging projects.