Among the longest operating amusement parks in the USA, historic Arnolds Park sought improvements that would create a new performance venue with accompanying amenities and expanded capacity, while preserving the view of the city’s signature West Lake Okoboji from the park’s open green space.

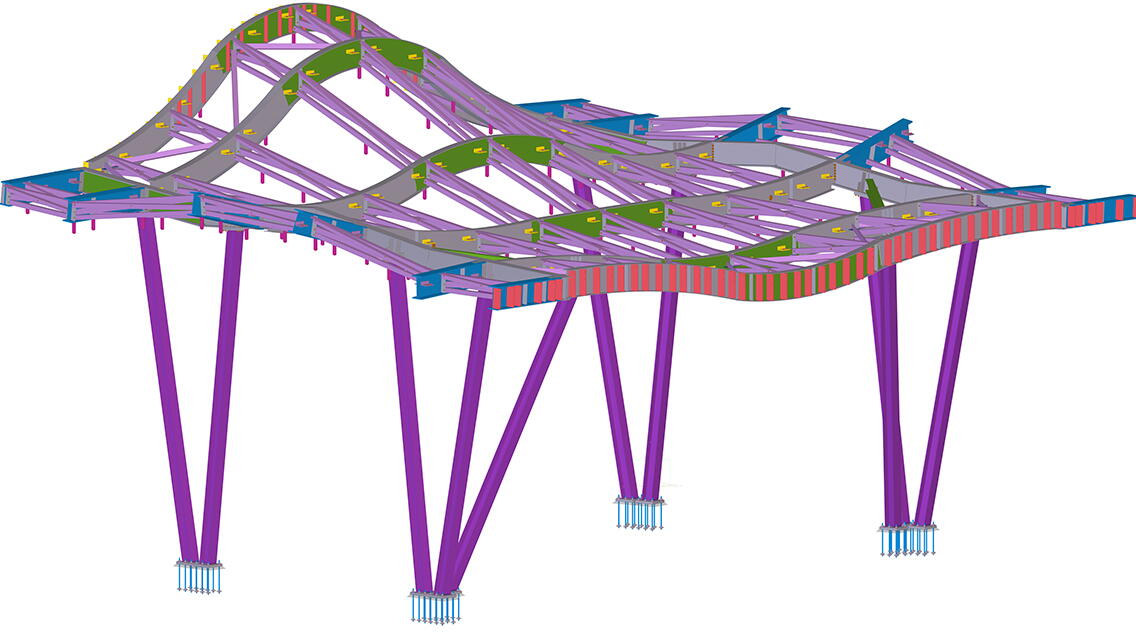

The Historic Arnolds Park Incorporation (HAPI) desired to transform the area into a permanent event space. The green space frequented by lake goers for events was converted in to this Preservation Plaza Canopy that offers yet another unique experience to the charm and delight of the area and serves as a cornerstone anchoring the park for enjoyment by future generations.

Challenges

It was essential that the structural improvements fit the context of the historic theme park and adjacent natural heritage site, including meeting requirements defined by the local Natural Heritage Committee.

Therefore, the team had a number of challenges while delivering the projects such as with the bottom connection of the double-slanted column. The double tilt of the column was indeed a hurdle for the team especially with the additional requirement for rat holes to be in a flat position. Here the base plate condition posed a significant challenge.

Next task was the construction of the section beam. The I-section beams, composed of plates and designed as plate girders in a rolled condition, presented difficulties in achieving the required radius from an architectural perspective.

Splice connection stood out to be a challenge for the team. The splice connection, designed as a moment connection with rat holes in all plate girders, required meticulous attention to detail. They dedicated extra effort to accurately place and represent these plate girders in the drawings, ensuring seamless integration within the structure.

HSS brace and angle braces was challenging in accordance with the structural dimensions. The project team carefully analysed the design constraints and developed innovative solutions to achieve the desired connection.

Benefits of using Tekla

Tekla Structures’ optimum structural engineering insight enabled the project team to drive better decisions. To overcome the double tilt of the column, the team scrutinized the design constraints carefully and developed innovative solutions to achieve the desired connection.

Further, the software made collaboration among different teams super easy. The team employed their expertise and collaborated closely with the manufacturing team to meet the design specifications while maintaining structural integrity.

The drawing generated by Tekla was so precise that placing the plate grinders on the drawings was effortless thus ensuring seamless integration within the structure. Moreover, the team employed advanced modelling techniques and multiple views to ensure precise positioning of brace elements, both in the design and the accompanying drawings.