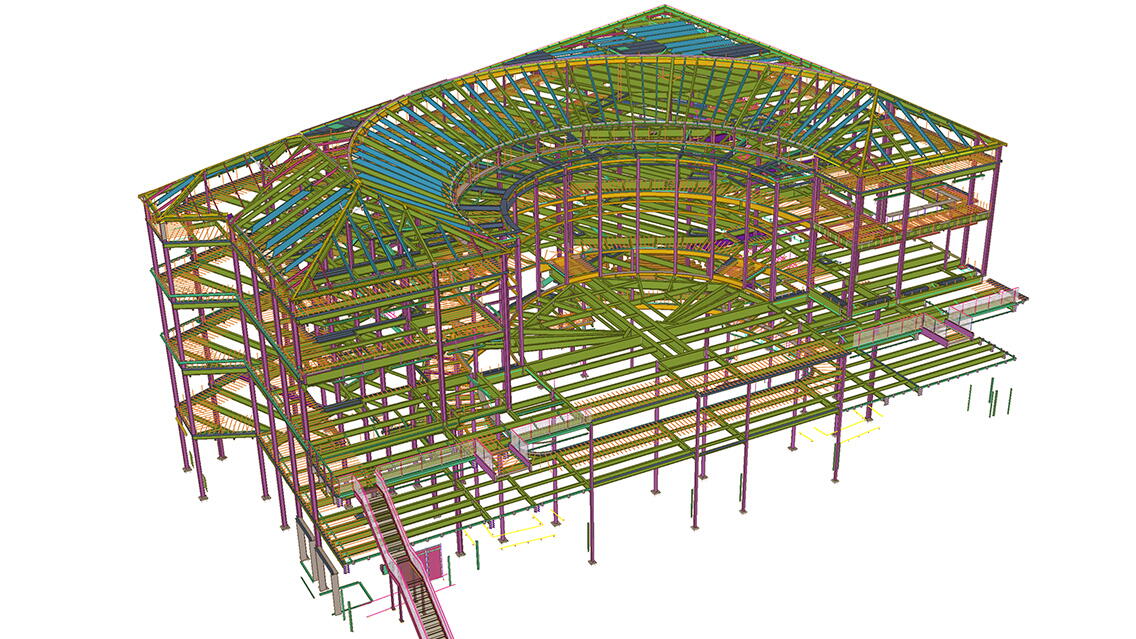

Mcintire School of Commerce is divided into 3 areas namely;

- Cobb hall (coordination with existing building)

- Shumway hall (newly constructed building)

- Rouss Roberston hall

Cobb hall building is a 5-level building that connects to the existing building and, member placement required the existing slab elevations and wall locations.

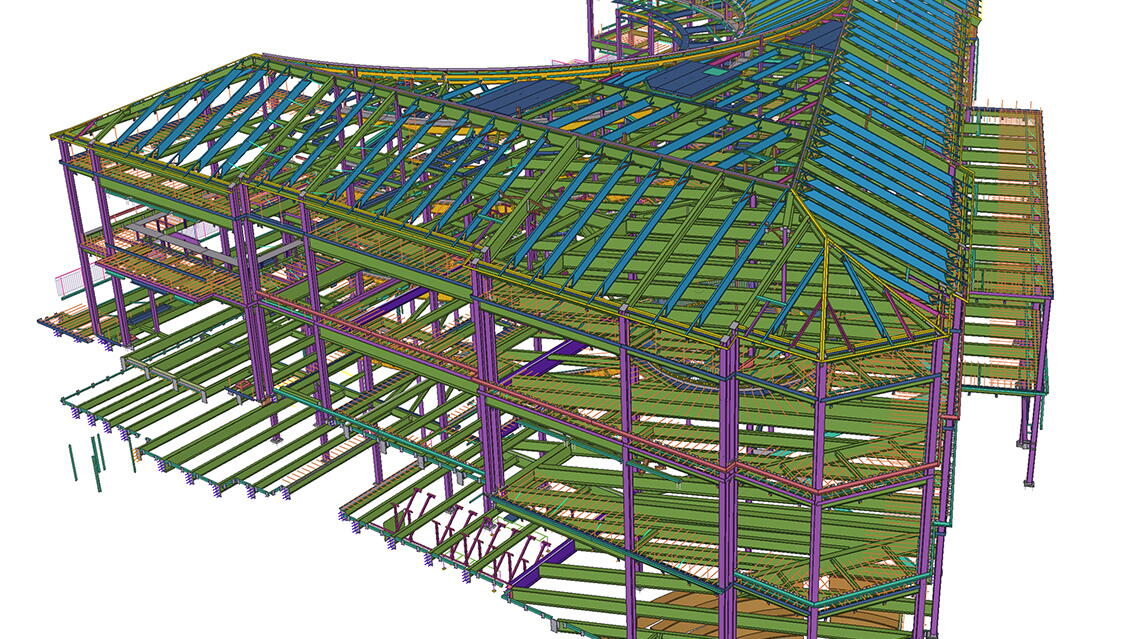

Cobb hall building had a complex task of coordinating with the existing building. With the help of BIM coordination and Tekla Structures, IFC & 3D DWG models, the executing team achieved accurate results and the field modifications were avoided.

Shumway is a 5-level institutional building with multiple plane roof surfaces. Each floor needed coordination with plumbing, electrical, mechanical, joist, stair & elevators.

Complexities In the Project

- Roof has 9 planes (1 conical plane) formed with 4 ridge lines, 10 hips & 1 valley

- Coordination with other trades (plumbing, electrical, mechanical, joist, stair).

- Modelling two-way sloped members (modelling designed connections)

By usage of BIM technologies like Tekla, the project team reduced errors and prevented onsite collisions with other trades. BIM helped in managing the modifications much more effectively.

Benefits of using Tekla Structures

By using Tekla Structures, the project team completed multiple complex tasks as follows:

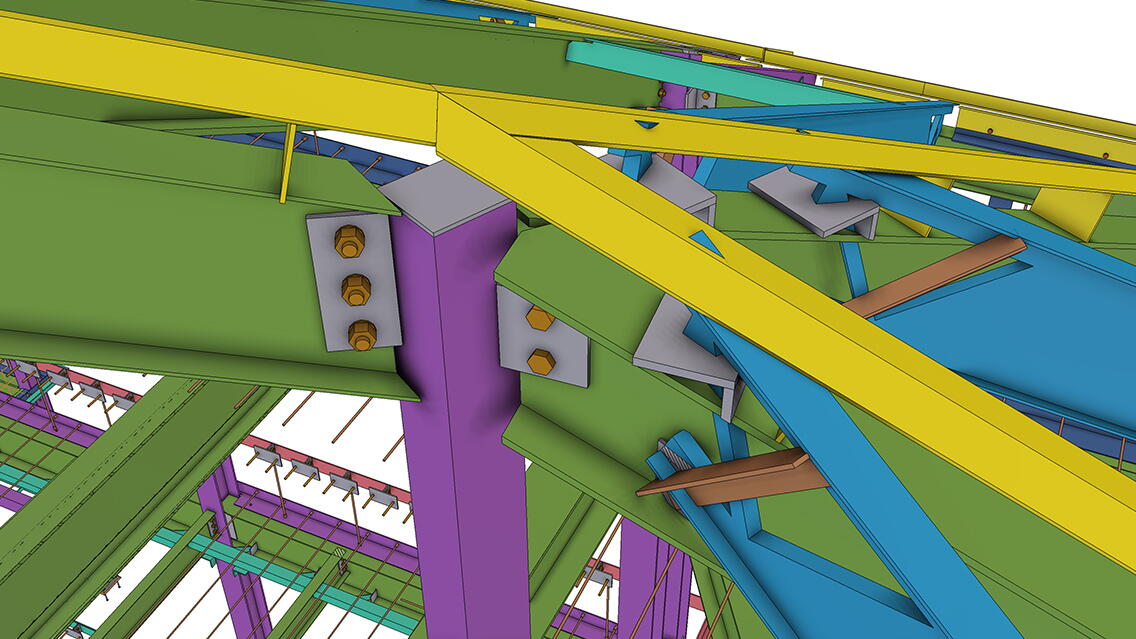

- Determination of the intersection points for the exterior face of the wall at corners - With Tekla Structures, the project team achieved accurate dimensions for modelling the wall locations at intersections.

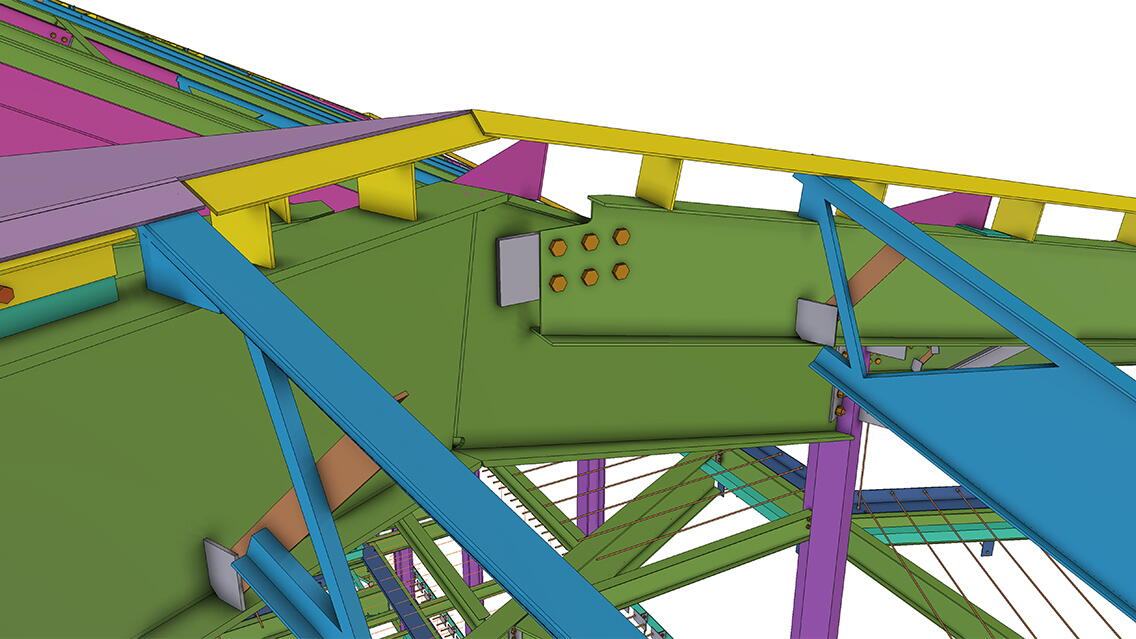

- Rolled members, which intersect to radial points - By using Tekla Structures the team achieved the required connecting points and modelled connections.

- Conical plane roof connecting to the ridge line at vertex point - By using Tekla Structures the team modelled the roof which had 9 planes including one conical plane formed with 4 ridge lines, 10 hips & one valley line.

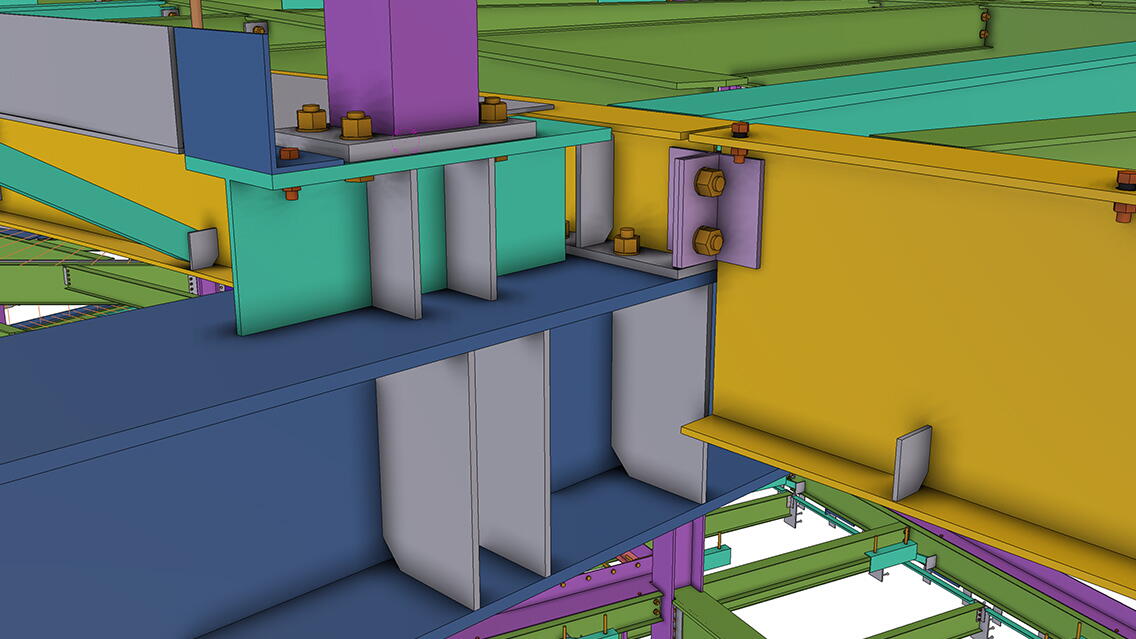

- Coordination with other trades (HVAC units, ducts, plumbing lines, ceiling planes, etc.,) - By using BIM coordination the team achieved coordinated models with other trades and achieved accurate results.

- Modelling roof conical bent plate - By using Tekla Structures the team modelled conical bent plates easily by using plates.

Takeaway

- Tekla steel detailing, Tekla Structures, IFC , 3D DWG models enabled the team to complete offsite work smoothly, further reducing the time spent onsite.

- Fabrication with EPM tool (for NC files, drawing files, XLM report) made the job easier for the project executing team

- By using Tekla steel detailing, two-ways sloped members’ detailing and fabrication was on-point.