Positioned in central Florida, it sits about 20 miles (32 km) to the south of Ocala and roughly 45 miles (72 km) northwest of Orlando. As of the latest 2020 census, the population of this CDP reached 79,077 residents.

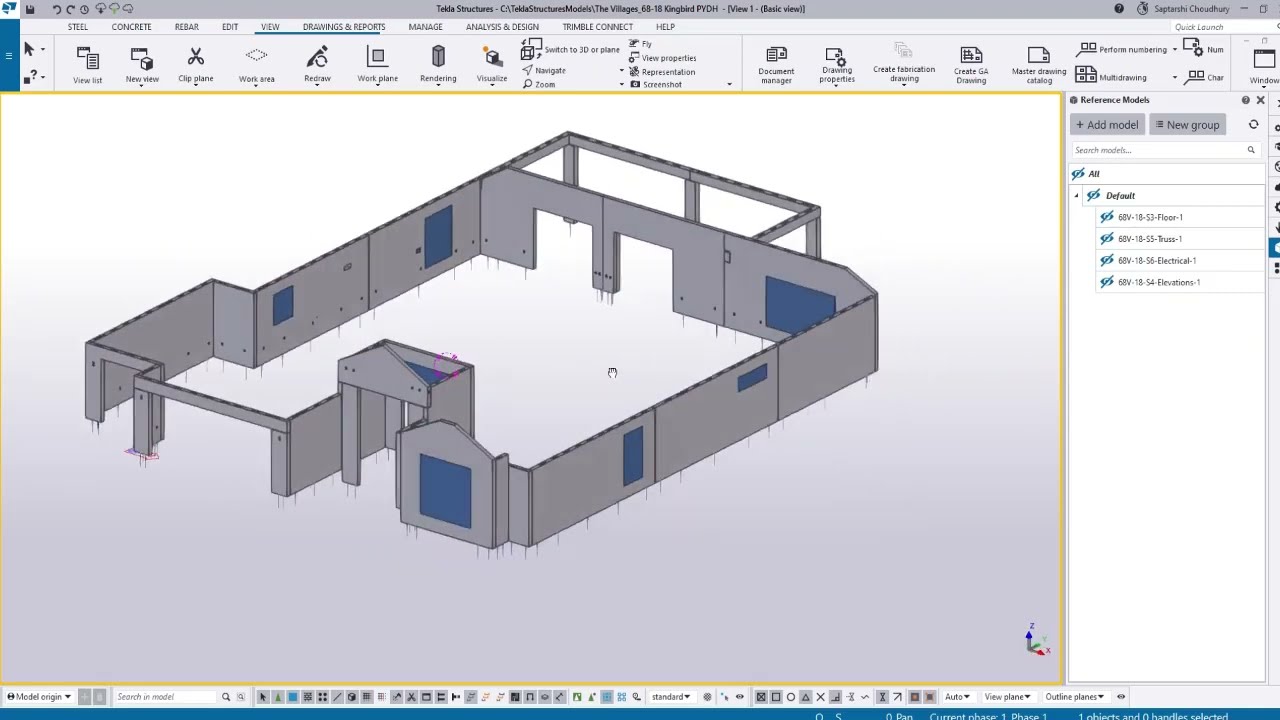

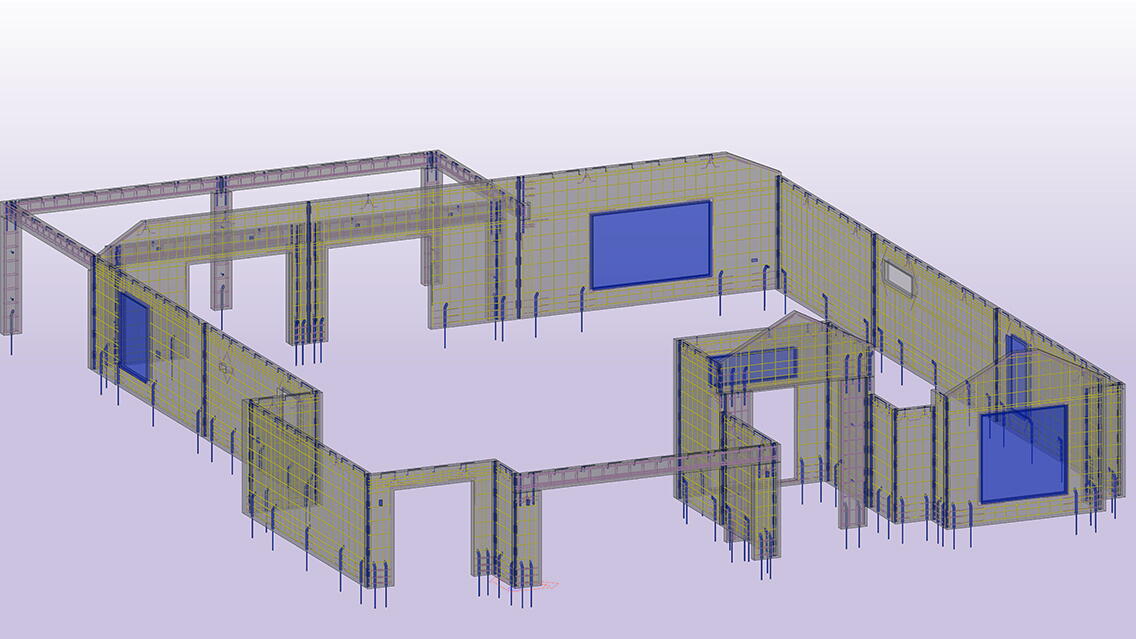

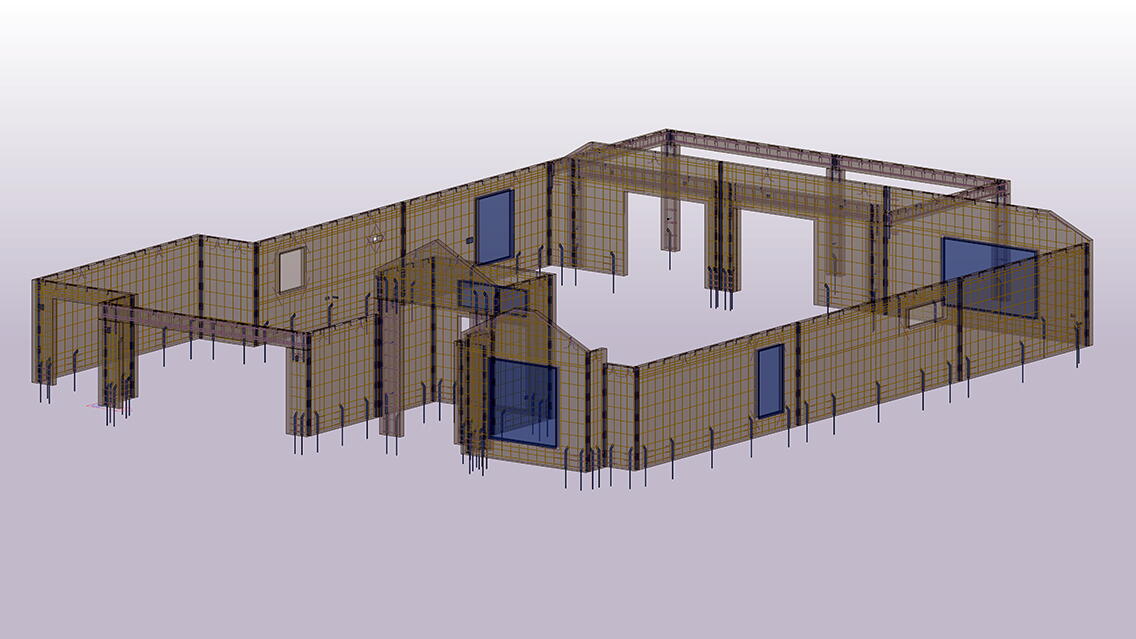

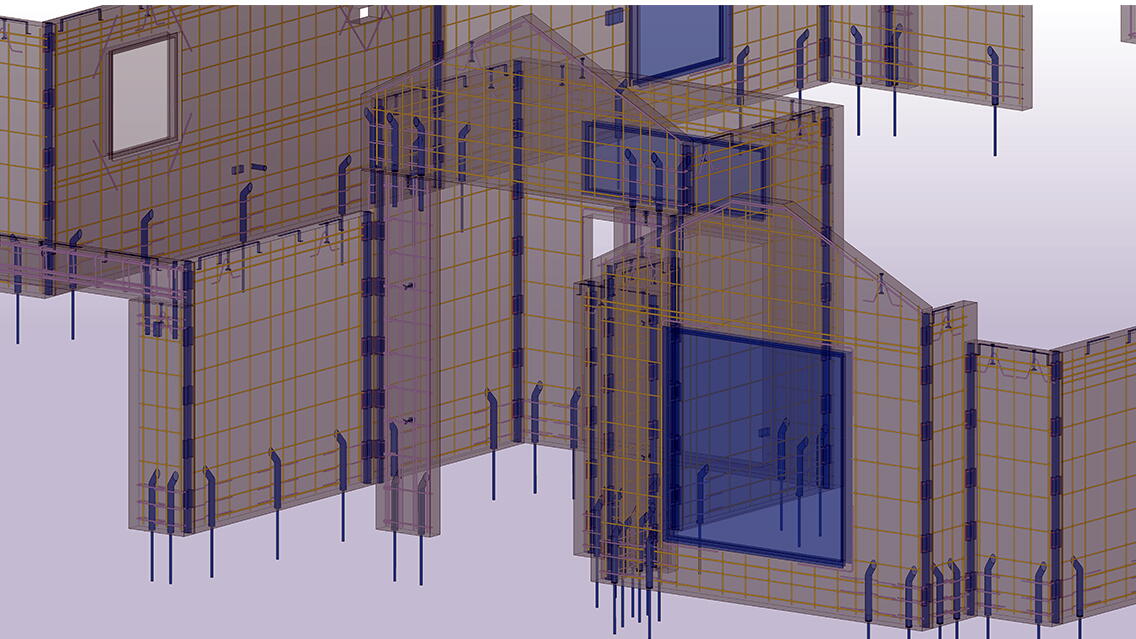

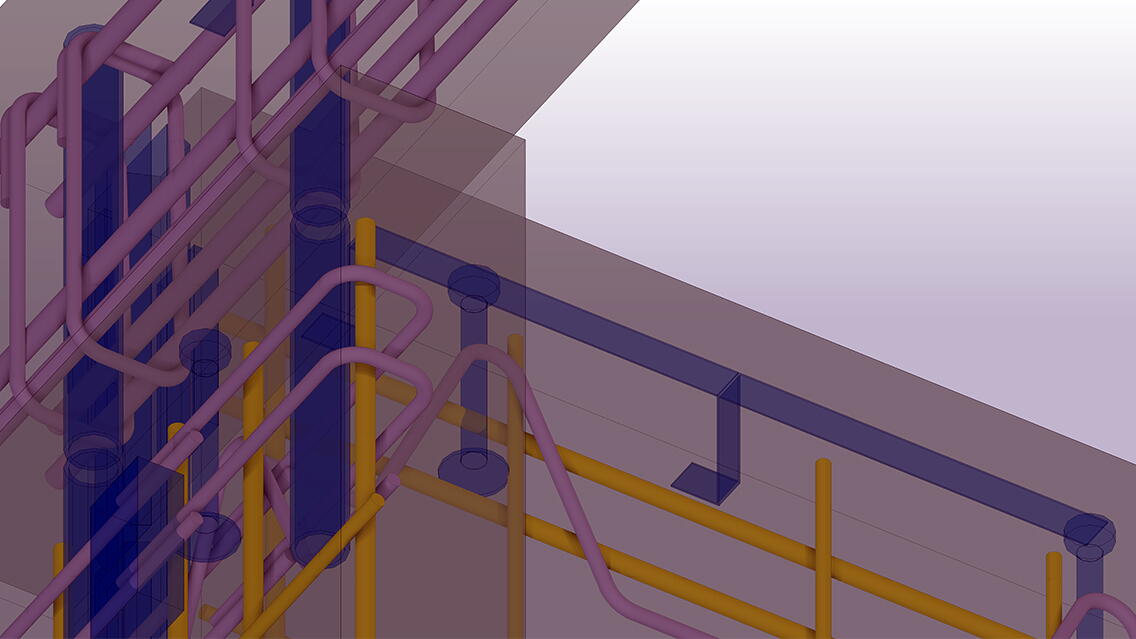

The scope of work included precast concrete model creation, hardware placement & panel reinforcement connections between elements, constructability review, panel placement/GA drawings preparation, piece ticket drawing generation, separate export file (.fbx, .asa, .bvbs, .ifc, etc.) extraction, AViCAD (pxml) file export for the shuttering robot to panel production.

The specialty of the project is its size however it is divided into small units. The project team has submitted 500+ models to the client and many more are under process. The project is expected to complete in the year 2033.

Challenges

Collaboration issue: This project engages over 12 individuals across different segments to execute the model, making it challenging to ensure smooth progress. To facilitate seamless collaboration, an efficient software platform was a necessity that allows access to the model and enables the team to work from different locations and time zones.

Huge number of panels with different precast elements: The volume of the project is enormous. The precast services includes concrete modelling, reinforcement modelling, panel drawings, GA drawings, etc. Every panel is different from the other. To achieve the daily goal including concrete precast modelling and creating piece ticket drawings was challenging.

Scheduling, transportation & other challenges: It was difficult to get the bar bending schedule in the shop drawing after the reinforcement of the panels in the CAD platform. Also preparing the huge amount of precast panels manually was extremely challenging for the production team.

Benefits of using Tekla

- Tekla software helped multiple users across different time zones of the world to work simultaneously & safely in the cloud server. The Tekla Model Sharing software offered seamless and error-free collaboration among the different stakeholders and members of the team involved in the project.

- The ‘Copy Special’ & ‘Copy From another Model’ commands enabled the project team to automate the repetitive work and save significant time. The automation feature helped the team to complete the project within the timeline with greater efficiency. Also using different components was very helpful to save time. Clone drawing & clone from other model options were one of the key aspects of using Tekla software. After modelling, the team used Tekla cloning function to produce several shop drawings at once.

- Using the Tekla templates, the team generated the BBS as required. The exporting of the PXML files was equally easy and these were directly uploaded to the production machine. The robot created the panel exactly as the model.