The Lotte World Tower is considered a symbol of the Lotte Group. It is the fifth tallest building in the world, the first 100-story building in Korea and is called the national landmark.

Lotte E&C is the main contractor for the Lotte World Tower construction project. The project was commissioned on November 11, 2010, and completed on February 09, 2017.

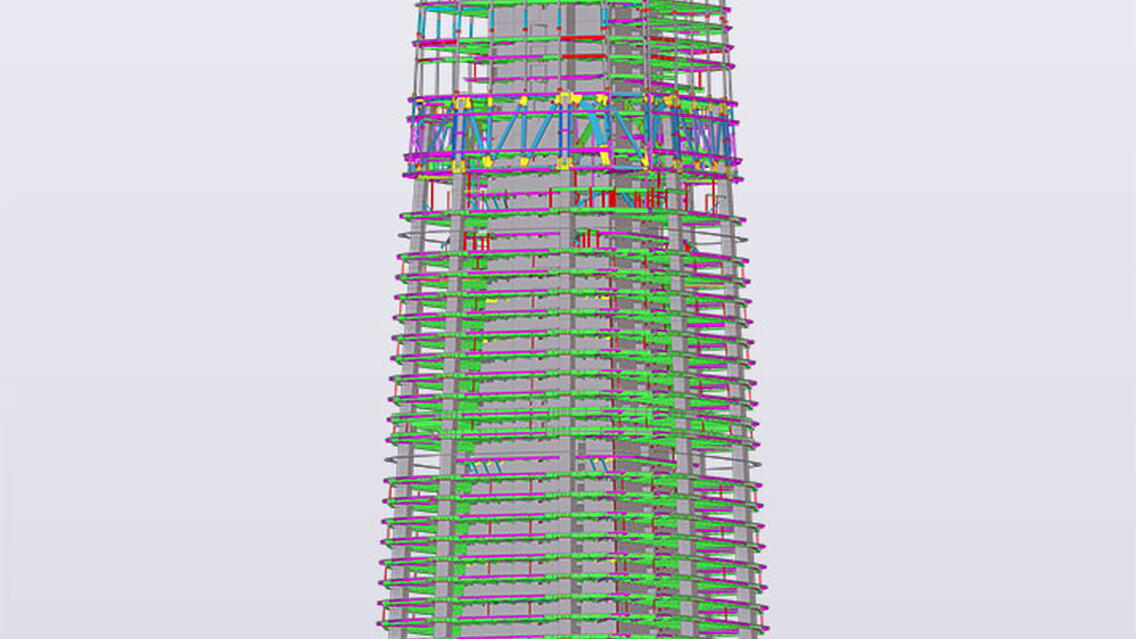

Lotte World Tower consists of a podium and a tower and includes retail, offices, residential, hotel, and tourist facilities. Lotte E&C had implemented BIM from the beginning of construction phase in consideration of the complex design of various facilities and super high-rise structures, and it contributed greatly to improve design quality and constructability.

Challenges and success factors

1) Difficulties in special structure construction

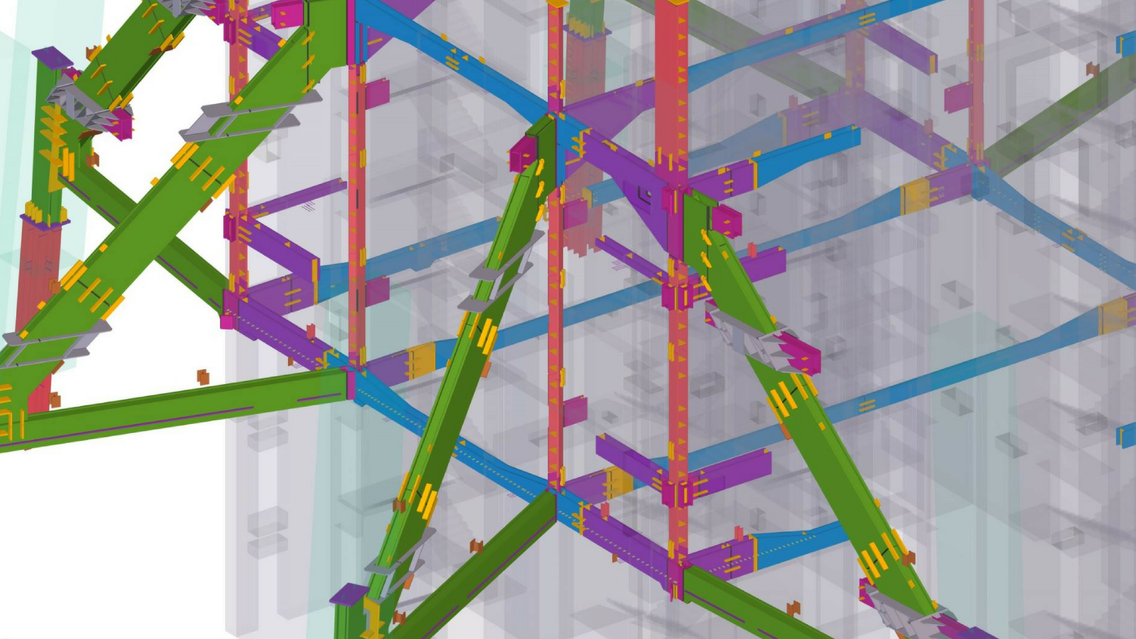

The construction of special structural systems such as the outriggers, belt trusses and diagrids of the Lotte World Tower across four sections was complex and challenging. In order to successfully construct this structure, a complete construction plan had to be preceded. Tekla was utilized as followings in this regard:

- Segment plan considering size and weight of each special structural part

- Reflecting clash check between steel and rebar

- Examination of constructability for both temporary and main structure elements

As a result, the construction period for the most complex outriggers and belt trusses sections (72~76 floors), could be reduced by 21%, from 95 to 75 days.

2) Difficulties in reviewing complicated structure drawings

In order to prevent risks such as delays in the construction period, it was necessary to confirm the irregularities in drawings quickly and accurately and provide feedback to the clients. Although it is possible to confirm the design errors or interferences from 2D drawings, it is very limited and difficult to communicate with the stakeholders about the issues. Therefore, to improve this, Lotte E&C had made the structure modeling process to be carried out in advance at engineering stage so that the design review can be done quickly and accurately.

In addition, the BIM model, which is a collection of design information for complex structures scattered on the drawings, is shared by stakeholders to improve the accuracy of information transmission and communication ability. Initial CD 50%~100% drawings were constructed as structural models. Also, about 600 design errors and suggestions were delivered to the client. As a result, about 90% of them were improved to revision drawings.

3) Concerns about the delay due to design & construction method changes

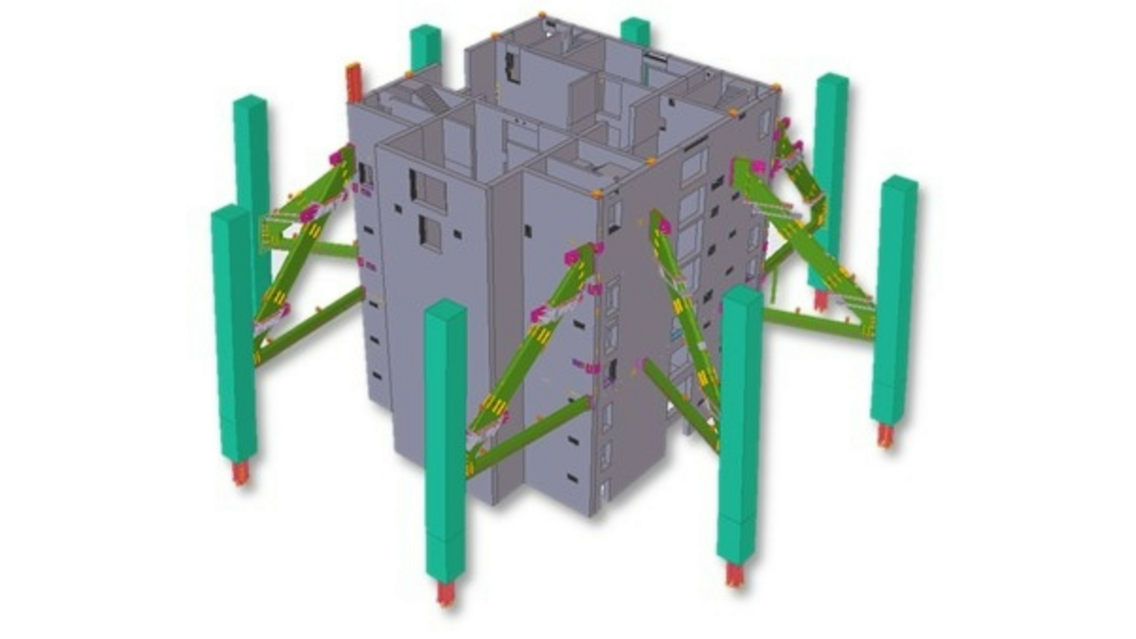

In the case of Lotte World Tower, design changes were made while applying the mega column succeeding construction method and steel structure proceeding construction method in order to shorten the construction period and improve constructability.

Accurate review and design must be presented to prevent the risk, such as construction delay caused by changing the construction method, but the time was not enough. In case of the mega column succeeding construction method, our design/structure team used Tekla to make three 3D design alternatives reflecting the intended construction method and confirmed the quantity variation due to the construction method change. After that, the BIM model was shared with the structural engineers and design was able to be decided quickly.

4) Design information confusion and communication problems

Due to the continuous design change, it was hard to share the latest drawings among the managers of various construction processes, so each of them had to work with different versions of the drawings. Thus, we found out delaying factors of construction process caused by frequent construction detail drawings’ change. In order to improve this problem, the initial BIM model was constantly updated according to the design change and we set up the process of maintaining and managing the latest BIM models. In this process, Tekla BIMsight .tbp file was used to share the BIM model with all related employees.

5) Lack of information on elements of irregular shapes

As the mega columns and core walls of Lotte World Tower are sloped, we need accurate coordinate information and shape information for construction. We utilized the Tekla models to extract the coordinates and shape information necessary for construction.

In the case of the curved ceiling construction of the lobby located at the 1st to 8th floors, the curved panels were designed by integrating the Tekla Structures models and the Catia models. By providing geometry information for CNC cutting and laser welding to the factory, the accuracy of irregular panel production was enhanced. In addition, dimensional tolerance analysis using 3D scanner and reverse design were carried out to ensure high quality curved finishes. As a result of applying BIM to the process, the curved ceiling construction, which was originally scheduled for 10 months, was finalized in 6 months and the construction period was shortened by 4 months while ensuring the best quality.

6) Difficulties in designing the complex machine room

The Lotte World Tower's MEP facilities are divided into 8 sections and the machine rooms consisted of many ducts and piping. We assumed that there were many errors of duct and pipeline drawings and reviews of usability. Thus, we converted Tekla model to Revit to use geometric information for the MEP design, to determine the location of the equipment considering constructability and usability, and the path and height of the ducts and piping. In addition, by designing the inside of the ceiling, the ceiling height was increased by 100mm compared to the existing ceiling height, which allowed the higher indoor space from 2,500mm to 2,600mm.

7) Accurate manufacturing for complex steel structure

NC(DSTV) files were extracted from the Tekla model and transferred to an automated processing machine. After that, steel and plate nesting were used efficiently for accurate manufacturing which reduced manufacturing error and time while pursuing high quality result.

8) Complex logistics plans for Lotte World Tower

By converting Tekla structure model to Revit, the layout and disassembly plans for the tower crane and hoist were established and temporary slab installation, pedestrians, vehicle tracks, and yard location were planned. Especially, the stability of the tower crane

dismantling from the high-rise building was secured by checking the interference between the structure and the equipment. The dismantling plan was simulated in Navisworks and used for the training for construction stakeholders.

Benefits from utilizing BIM and Tekla Software

1) Reuse of structure analysis model

By transferring the structure analysis model of MIDAS Gen and ETABS into the Tekla model using the previously developed plug-in, the burden of making structure model can be reduced at initial stage.

2) Construction simulation for complex sections

Tekla's project status visualization function can simulate construction process easily and quickly compared to other software. By using this

function, detailed process review was carried out for outrigger, belt truss, or various process combinations, and the results were shared with stakeholders. Visualizing complex processes not only improves the understanding of construction stakeholders but also reduces rework. In addition, it was possible to express the results of the construction and the future process plan, and it was utilized effectively when reporting to the clients and external organizations.

3) Convenient and easy communication by sharing BIM model

Tekla BIMsight integrates Tekla's structure models as well as other division models as MEP, Civil, Architect to support interference checking and visual review. Construction officials disseminated their opinions on BIMsight's Album and Note on detailed review items, which helped others to understand for optimal decision-making. In addition, contents review and decisions were accumulated in BIMsight’s Note and the history of the work could be managed.

4) Accurate quantity

For large and complex buildings like Lotte World Tower, the 2D-based quantity survey would be less accurate. Therefore, we used Tekla Structures model to calculate the quantity of steel, concrete, and some rebar accurately and quickly. Especially, in case of the built-up components such as outrigger or belt truss, the Tekla based quantity calculation provided more confidence for the project.

Other Trimble tools & software utilized in the project

We confirmed if the construction base points were same as the BIM 3D model's coordinates for curved ceiling construction of the lobby from 1st floor to 8th floor, by using Trimble's total station.

Using SketchUp by Trimble, we were able to quickly review various alternatives to change the finishes’ design of the curtain wall horizontal beam on the 1st-floor lobby.