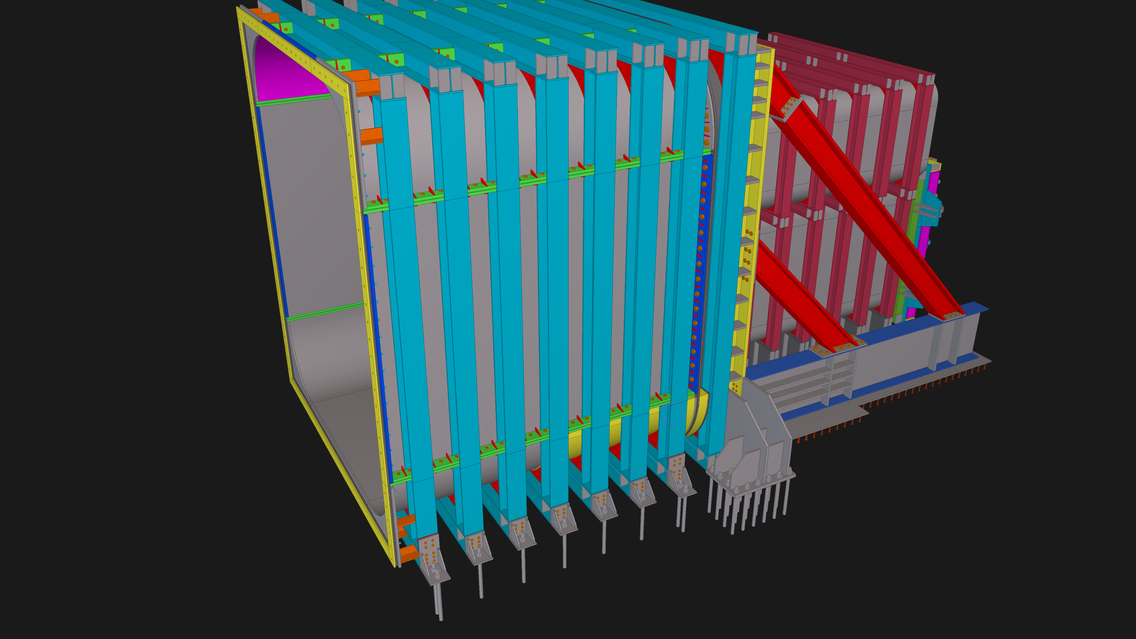

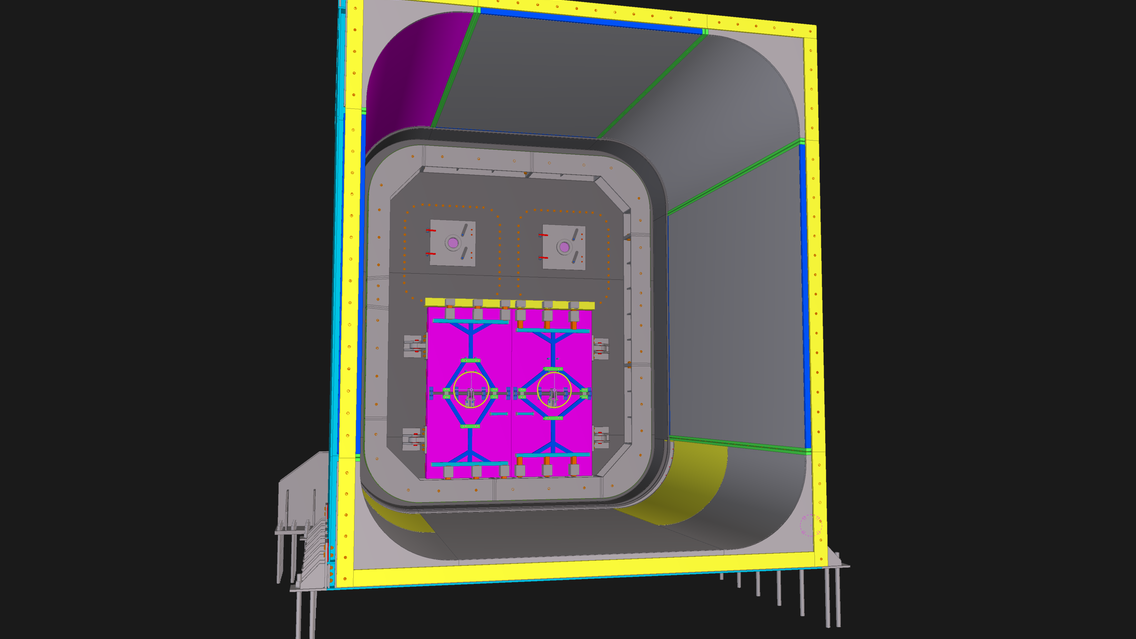

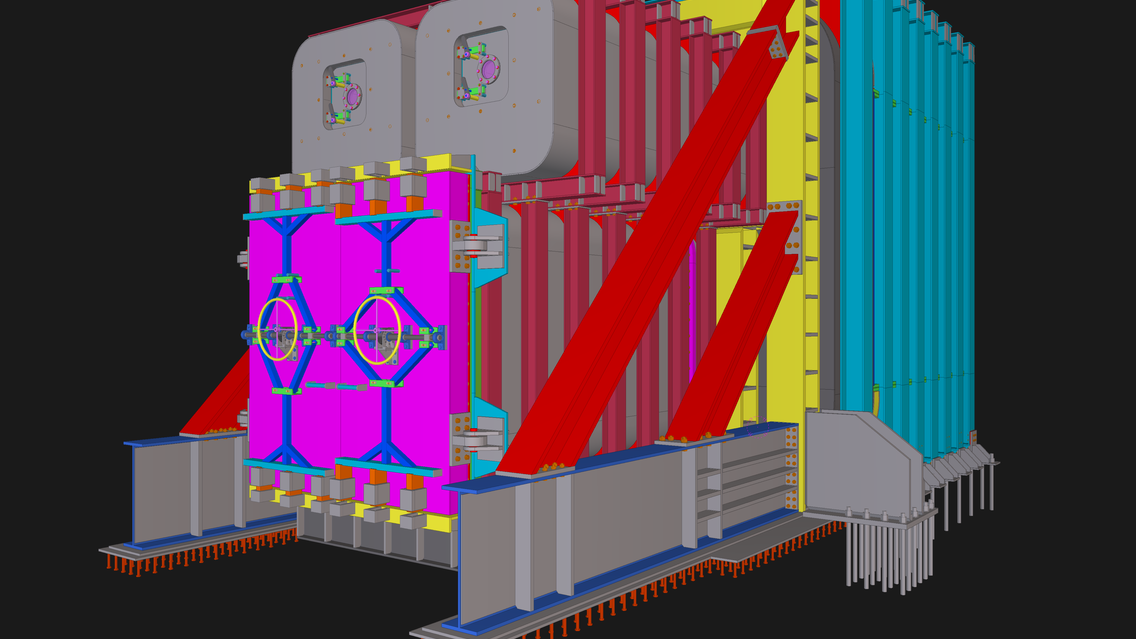

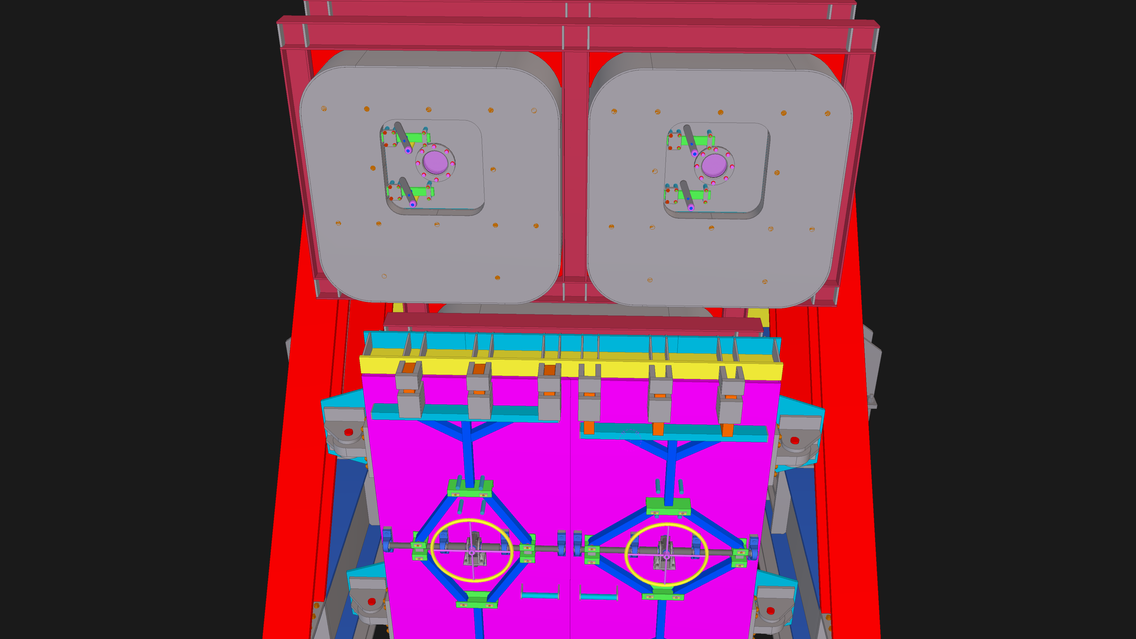

The model was done by TTJ Design & Engineering for Taisei Corporation and is a pressurised steel structure chamber for a special tunnel boring machine (TBM).

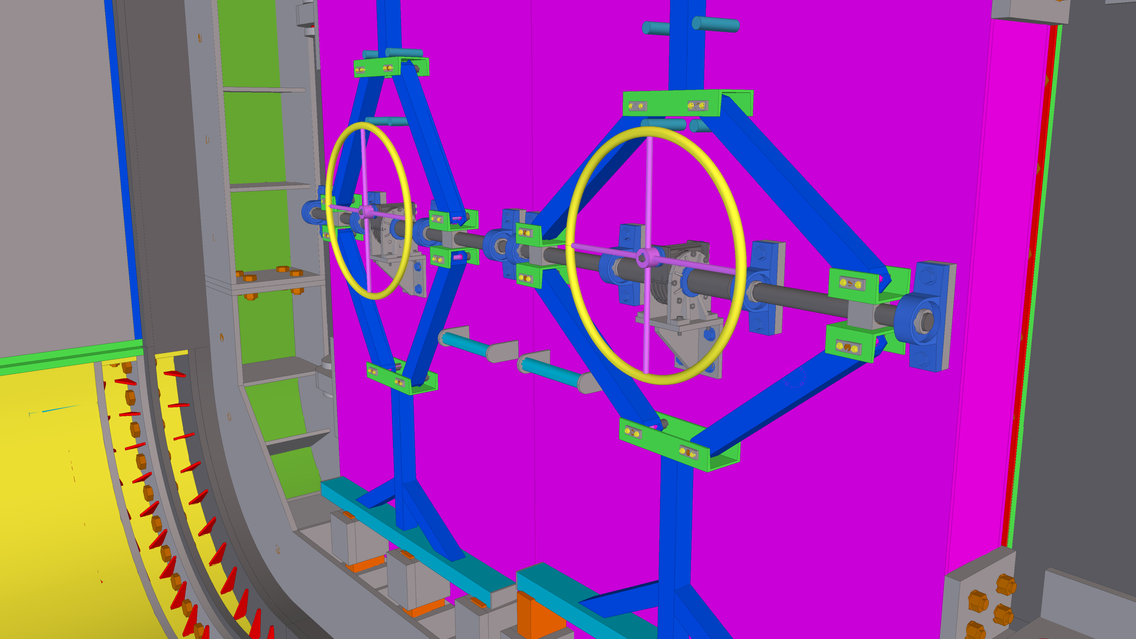

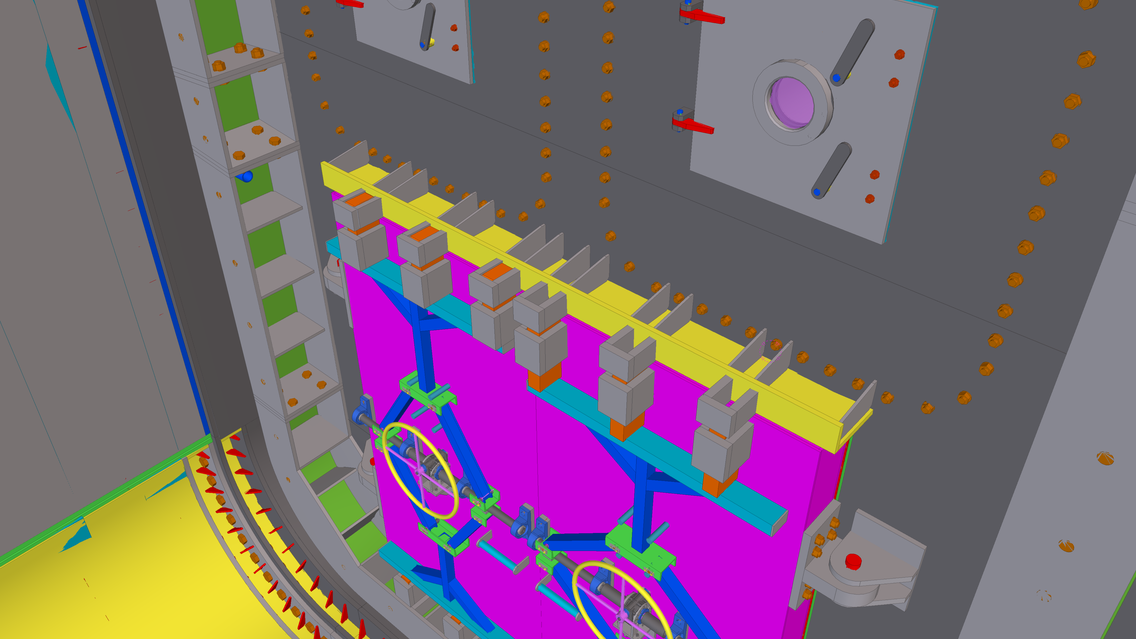

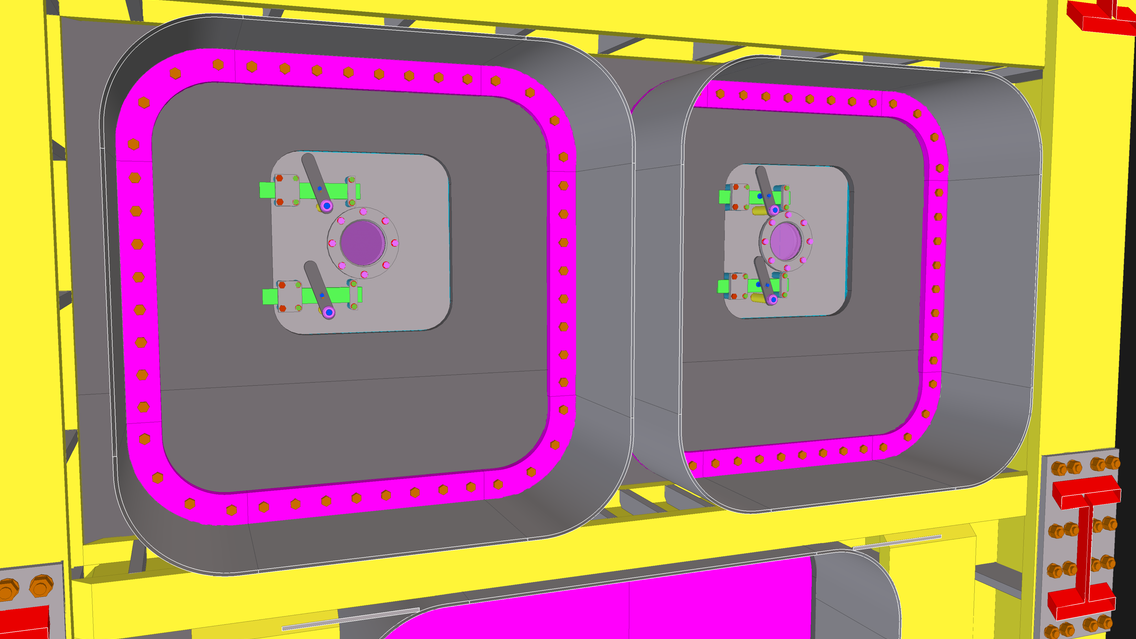

It consists of two man locks to provide access to operators, one material lock for material cart to transport excavation moves forward, Bulk Head, Reaction Frame, Ring Segment, Main Chamber, two Material Lock Hatch Doors and six Man Lock Hatch Doors to satisfy the requirements of air locks for tunnelling machine.

TTJ used Tekla Software for the whole model and it is really beneficial especially when it comes to Rolled plates. Since it has given precise information by software, both time and cost saving are very obvious for sourcing, rolling, cutting and forming etc.

Tekla BIMsight was also used to connect and to discuss with other departments on what was needed to be done and what was the best solution for fabrication, operation etc.

Company Description

TTJ Design & Engineering Pte Ltd is a structural steel specialist offering design, supply, fabrication and erection of a wide spectrum of structural steelworks for use in the construction of buildings, factories, plants and infrastructure. TTJ operates one dormitory in Singapore, with a total capacity of approximately 5,300 persons.

Their reputation as a leading structural steel specialist has won them contracts for many iconic projects in Singapore and the Middle East including, Changi Airport Terminal 3, the Pinnacle @ Duxton, the Singapore New Supreme Court, the Double Helix Duplex Stainless Steel Bridge at Marina Bay as well as the Bahrain World Trade Centre Twin Towers and the Burj Dubai Development Plot 12 & 13.

TTJ's structural steel business is currently being carried out in Singapore, Malaysia and Middle East. They presently have two fabrication facilities comprising the Pioneer Factory in Singapore and Keluli Factory in Johor, Malaysia which have approximate land areas of 17,000 sq m, and 86,198 sq m respectively. Together these facilities have a current combined maximum annual production capacity of 42,000 tonnes, making this company one of the largest independent structural steel fabricators in Singapore.

The factories are specially designed around an in-line production concept based on Computerised Numerically Controlled machinery. The Pioneer Factory's unique seafront access allows fabricated components and raw materials, for offshore projects to be transported easily.

As a testament to TTJ's commitment to quality as a company, they have been awarded ISO 9001:2000, ISO 14001:2004 and OHSAS 18001:1999. They are also accredited with the S1 grading, the highest grading by the Singapore Structural Steel Society, and one of only two such companies with design and fabrication facilities in Singapore.

TTJ's comprehensive manufacturing capabilities includes heavy lifting cranes, ship-lift platforms, piping systems for fluid processing plants, structures for high rise buildings and petrochemical complex, heavy roof truss, bomb shelter doors, steel moulds and launching girders for bridges and highways, pressurize vessel and tank, vehicular aluminum parapets, expansion joint and bearing for highways and roads.