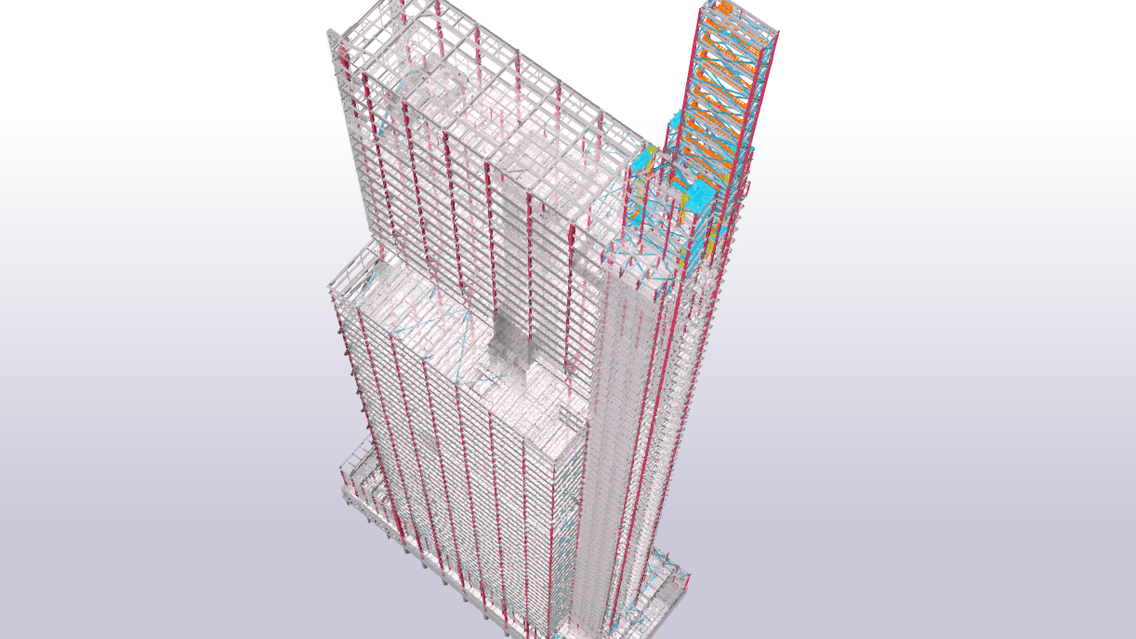

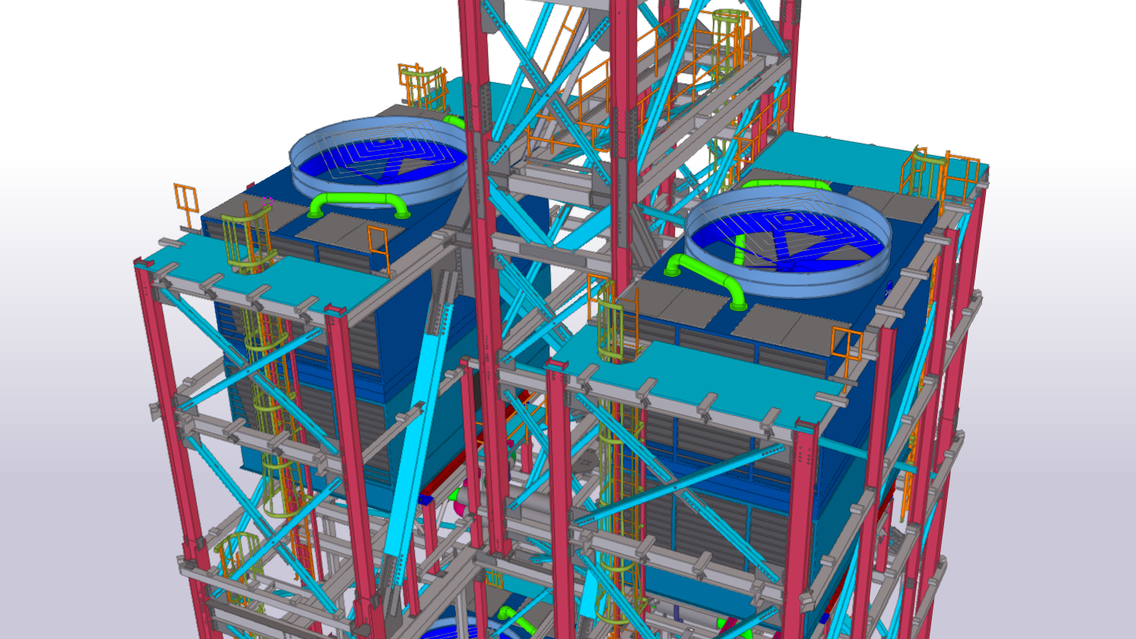

Comcast Technology Center is the newest skyscraper addition to the Philadelphia skyline. Towering over the city at a height of 1,121 feet it has become a part of American History not only as the tallest building in Philadelphia, but as the tenth-tallest building in the United States and as the tallest building outside Manhattan and Chicago in the US. The 60-floor building includes approximately 1.8 million square feet with a total steel tonnage estimated at 20451 tons. Instead of the traditional center-core high-rise for its new skyline-defining tech center another design was proposed. It included open, Google-like spaces for creative employee collaboration with a center core would cut through the open spaces. To do so, the core to the 19th Street side of the tower’s footprint shifted – what structural engineers call an “eccentric” or “off-center” core. That opened the office floors on the eastern side of the tower. Not only was it insisted on having an off-center core, it went one step further. It designed a split off-center core, or an off-center core divided into two parts. This is, conceptually, two concrete boxes running vertically up the building for stability. To stiffen the top floors, which were the most susceptible to powerful wind factors, an engineer team incorporated "chevron braces" on the hotel complex's east and west sides. The engineering team buried the A-shaped steel braces between hotel rooms so they are not seen or noticed. They are stacked on the east and west sides of the hotel, one brace on top of another. Blasetti's team also allocated space for five "tuned sloshing dampers" in the ceiling of the 57th floor, below the hotel sky lobby at the top of the building. The five dampers - holding 125,000 gallons of water - will act as a countervailing force when the tower sways in the wind. They will be hidden in compartments in the ceiling.

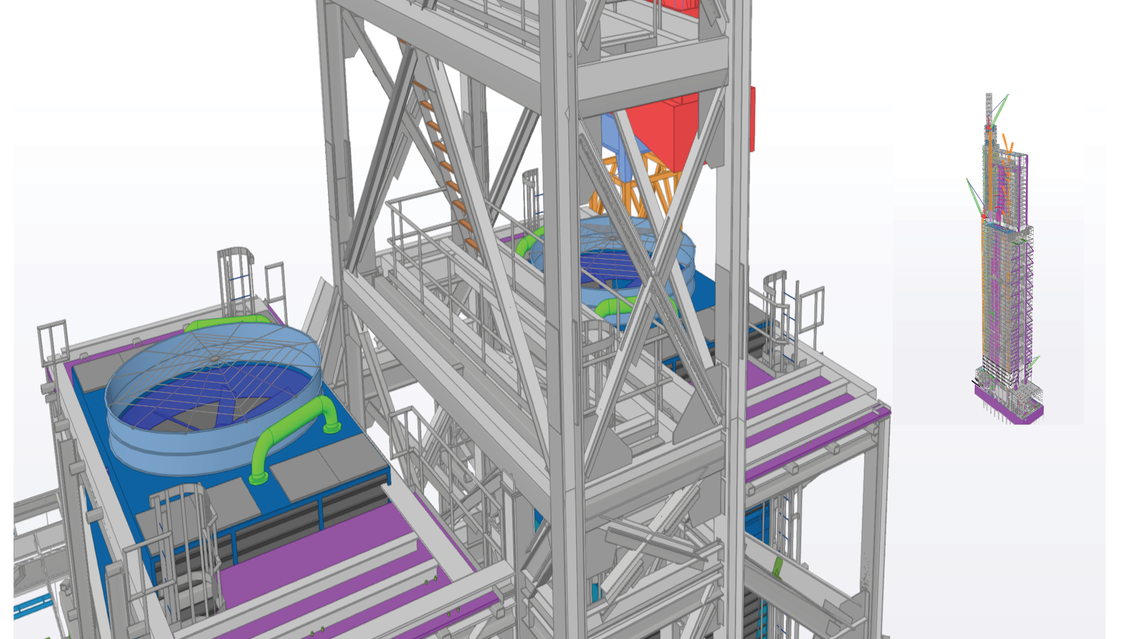

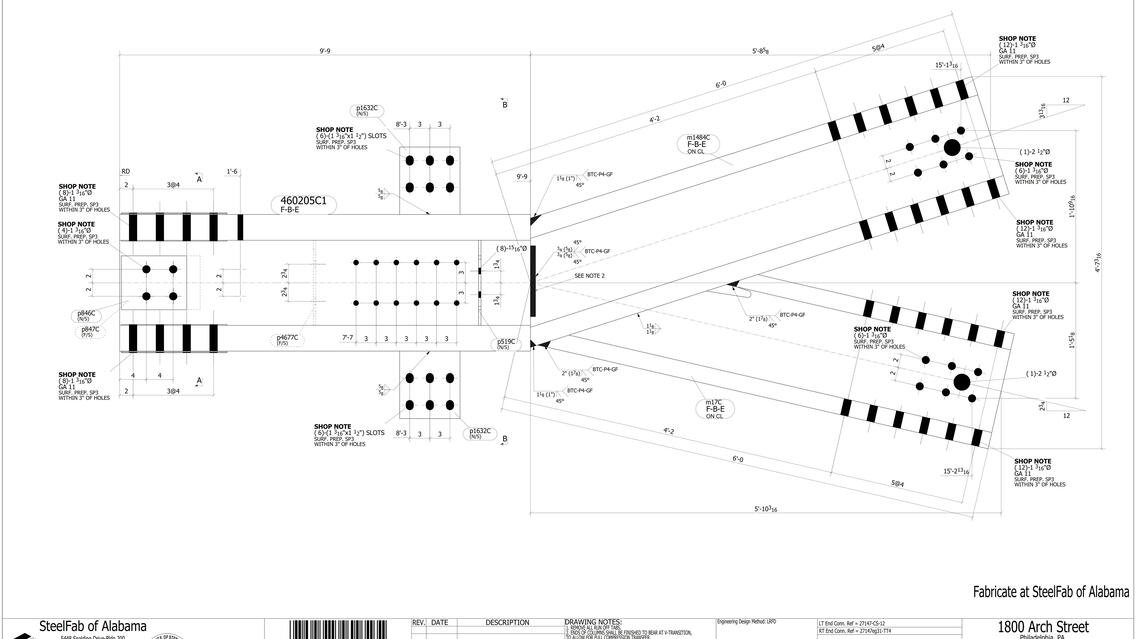

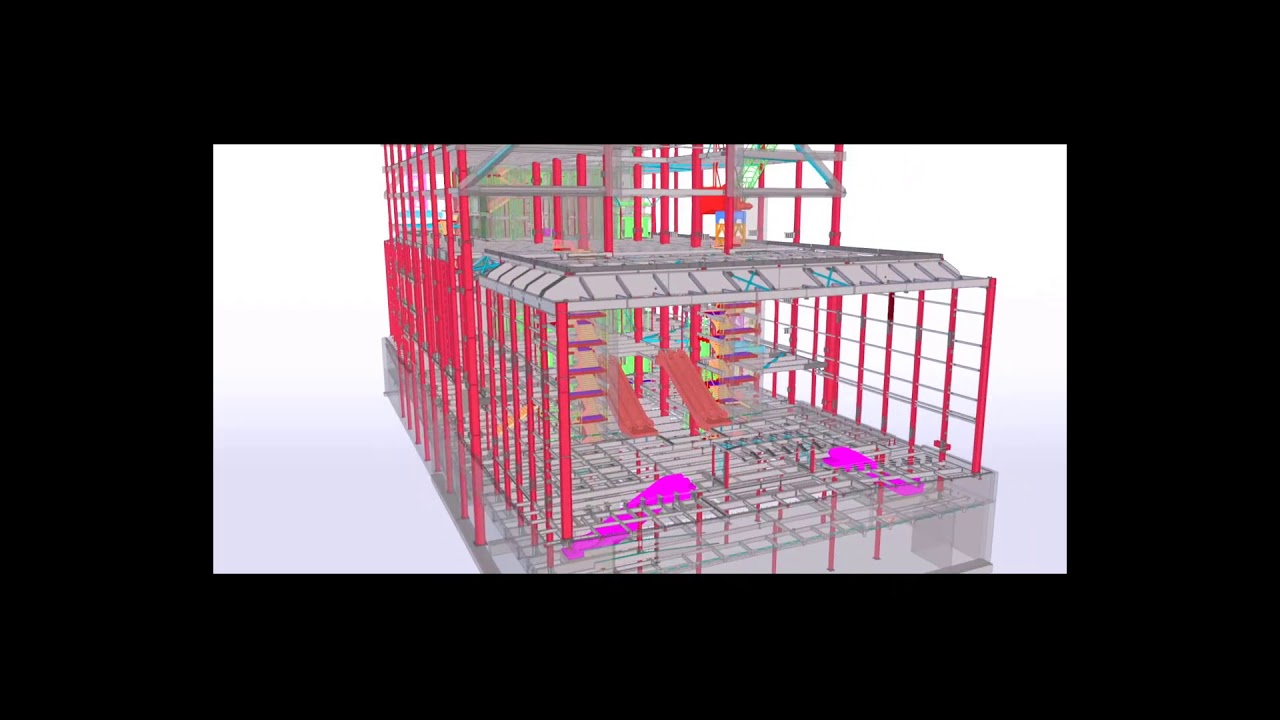

Thanks to the intelligent approach of BIM coordination, steel detailers were able to anticipate any problems ahead of time by using lightning-speed import/export of reference models exchange with other trades using the Tekla Structures software environment. They used a fragmenting approach to speed up the fabrication process, dividing the structure into separate models that could be detailed simultaneously ahead of time. All other trades based their coordinative models on the main Tekla Model used by the detailers.