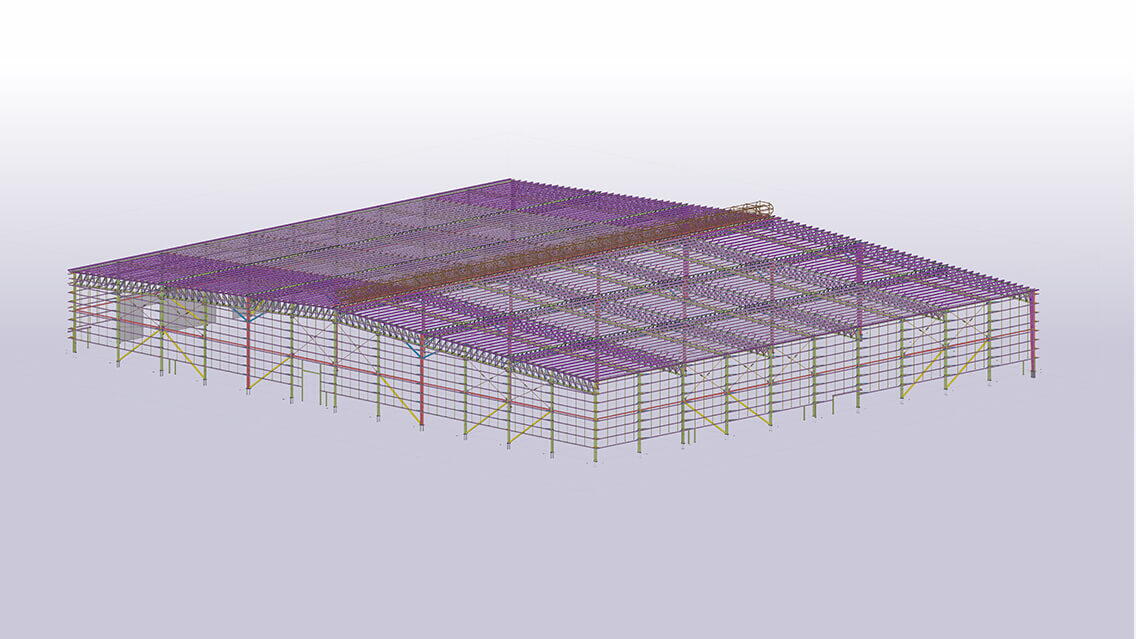

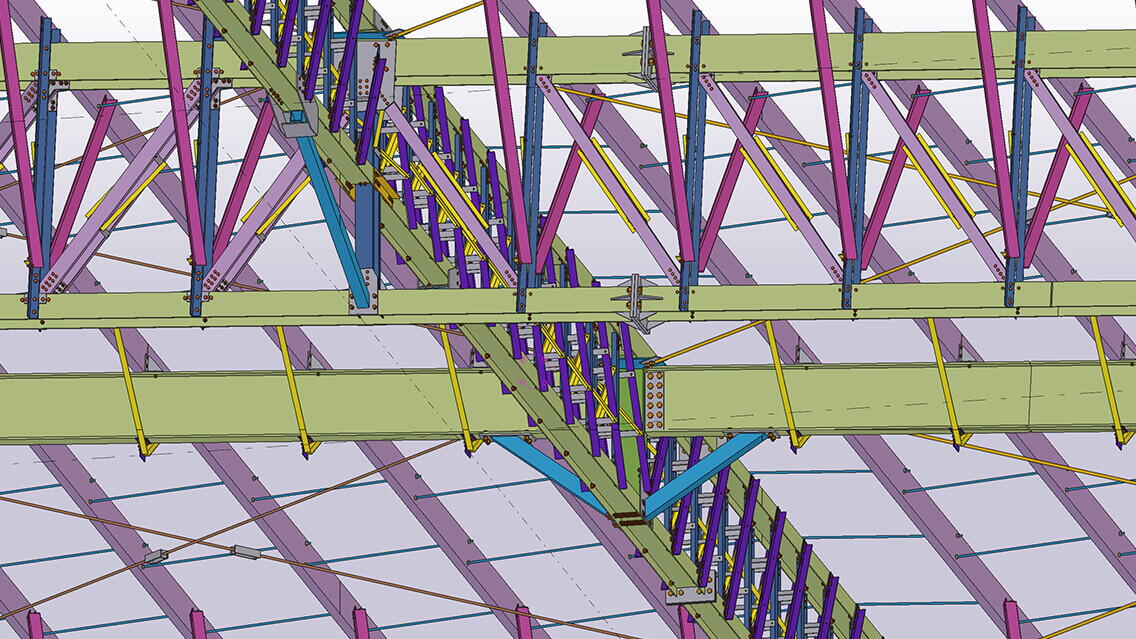

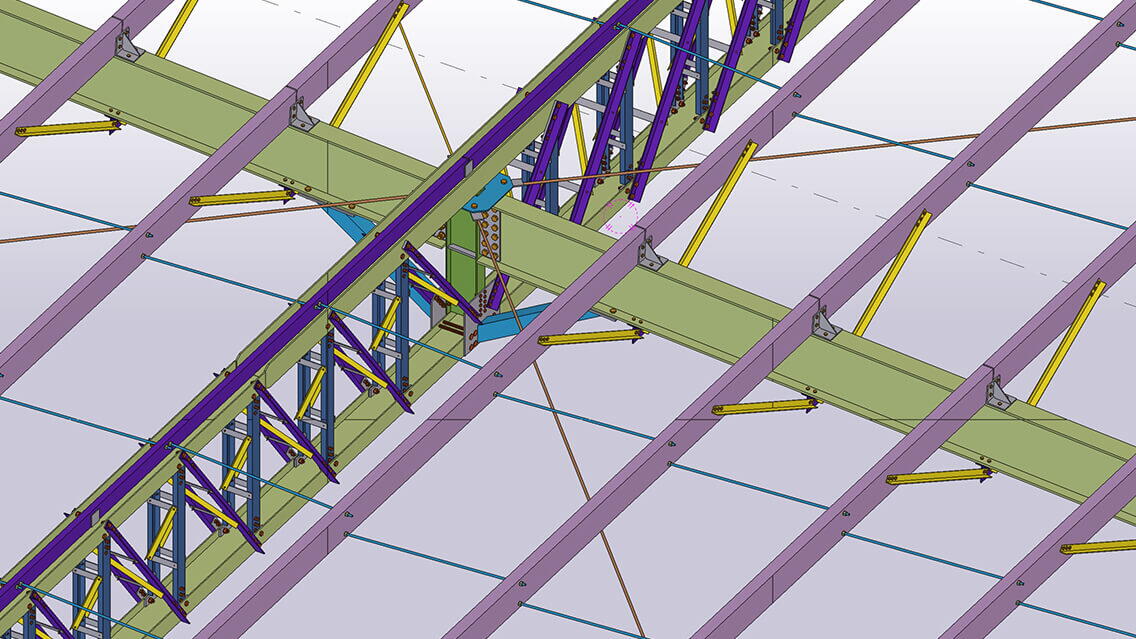

GKN 3 is a 12,000 m2 automotive plant in which Jaza Ingeniería was responsible of manufacturing and assembling the entire steel structure, which was conformed by a combined system of steel frames called Vex Truss and Vex Frame designed to achieve clearances of 40 meters in X direction and 20 meters in Y direction. This system consists of around 90% bolted connections, considerably accelerating manufacturing times in the workshop and erection times.

Challenges and achievements

This project was a big challenge for the company, as it was one of the first projects carried out with the Vex Frame and Vex Truss system, to achieve an efficient system with the spans required by the project and to be able to manufacture it in a short amount of time.

Using Tekla software

The use of Tekla Structures in this project was of vital importance, due to our processes that increasingly seek to be more automated, their interaction with several automated tools, such as thermal cutting robots, angle cutting machines, etc. it's simpler. The use of Tekla Structures has also allowed us to implement and experiment with new systems like the one in this project, where bolted connections are protagonists to offer customers better delivery times.