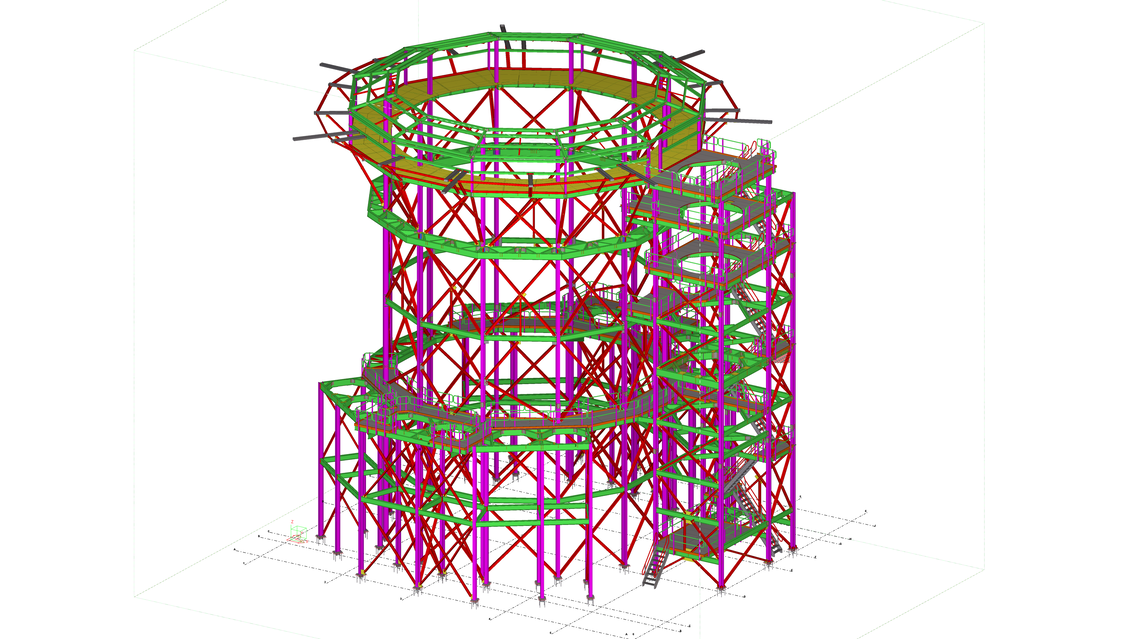

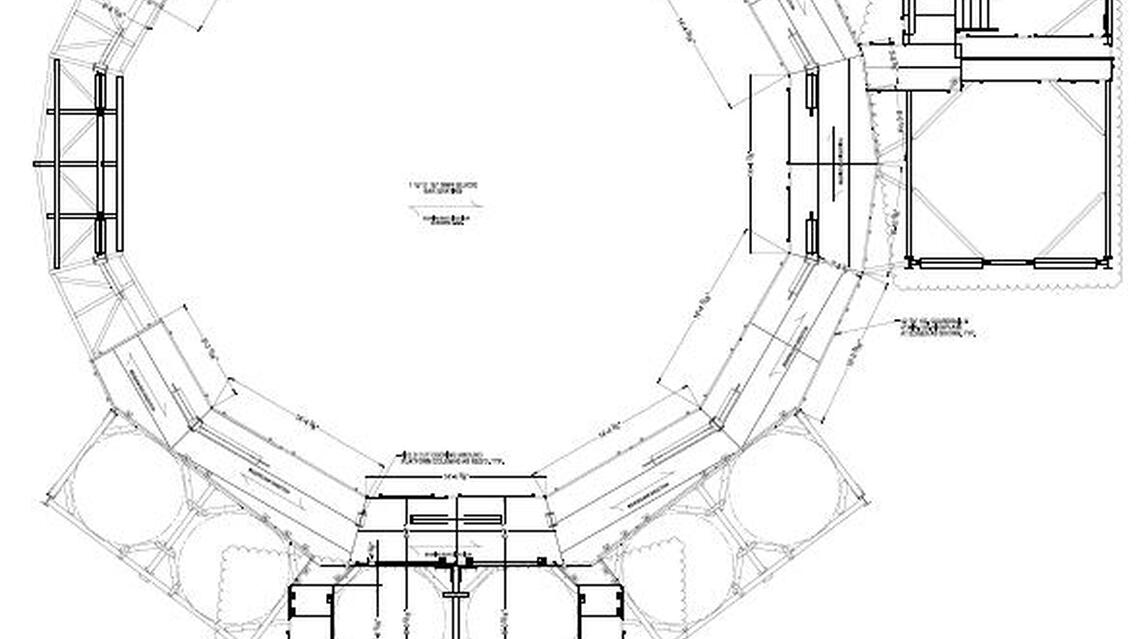

Designed for the mining industry this tower supports over 1MM lbs of Spray Drying equipment mounted at 72 ft in a high seismic and wind loaded area. During operation, the 58 ft diameter equipment under goes a 3 inch radial thermal expansion within the framework - not only is it large in weight and size, we have to allow for it to move within the framing. This is accomplished by a slider design but ultimately held in place by bearing blocks in case of a seismic or wind event

Coordination between customers, end user and Steele Solutions allowed for a successful design, fabrication and installation of the project. The circular design of the overall structure provided unique skewed connection design and force analysis that was accomplished thru Tekla Modelling and Bentley Staad Pro.

Tekla allowed us to model this project from start to finish, we were able to reference in customer drawings in order to see all clearance and interference issues. Due to the complexity and access requirements of the customer and equipment - we were able to see opportunities within the structure's framing and bracing to allow for a simpler design. The sections and erection drawings were created from Tekla and allowed for easy to follow drawings for the field. We also provided a BIMsight model of the project to the erectors in order to ease the process and share information.