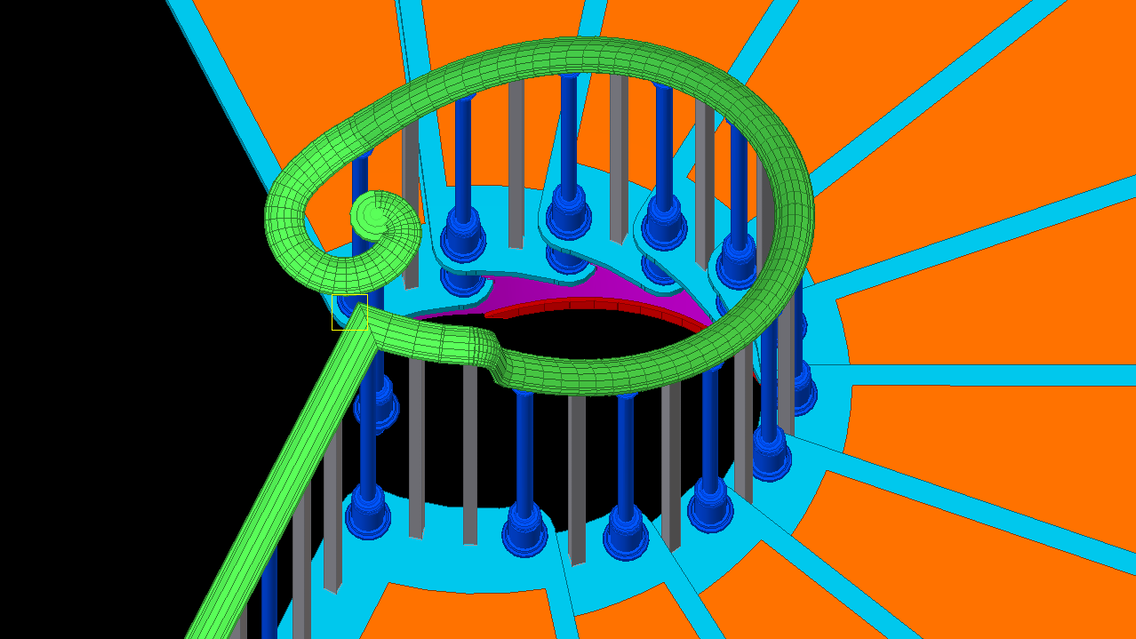

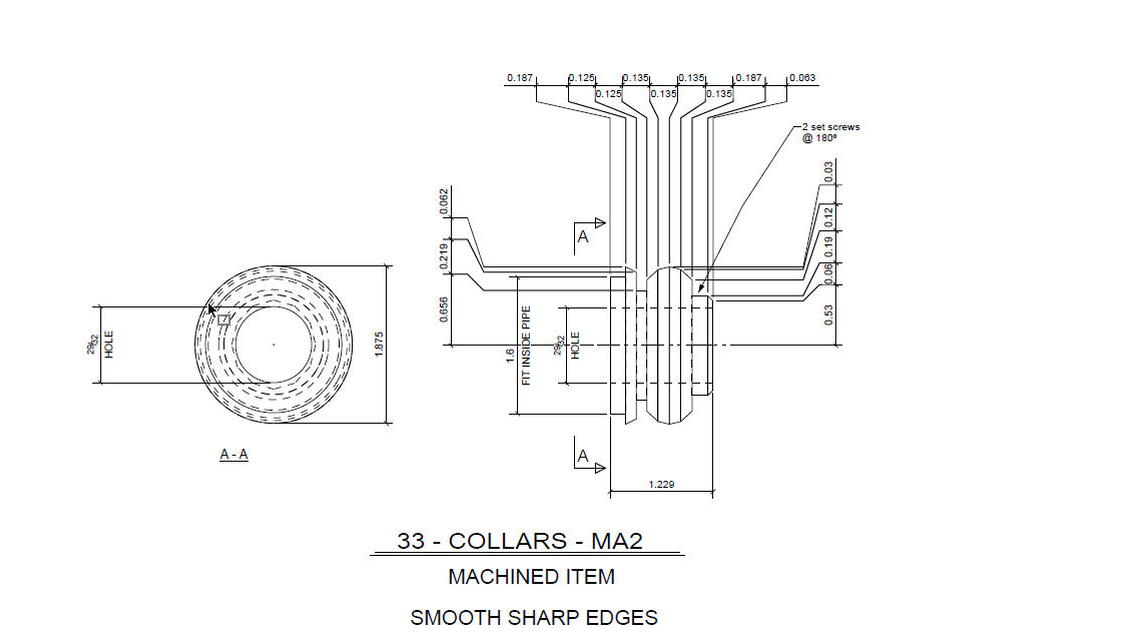

The customer desired to have a highly decorative, but functional helical stair as one of the main show pieces in the “Banker Hall” where guests are waiting in queue to get on the main ride. The building was also completely closed in with beautiful Terrazzo floors all around the stair location we when got this job, so we realized early on that we had to hand carry each piece to its location and assemble it in place. The main challenges on this job were the columnless design, the helical stringers, the creation of a hammered look on the stair treads, creating a solid steel cast look for all the members AND keeping the weight down for erection purposes. The modeling and fabrication of the curved and twisted molded rail cap also needs to be mentioned here as well as the requirement that nowhere on this stair welds or mechanical fasteners could be visible for the guests. We used the combined capabilities our fabrication and machine shop to achieve the desired results. For example: We used the plasma cutter to rough cut the 1" think stair treads. After that we machined the curved edges and created a 1/2" recess at the underside of these treads to bring the weight down to a manageable level. We also use the waterjet to cut thin hammered tread plates that we adhered to the blasted and unpainted area of the treads. The stair came out great and Universal Studios Orlando was very pleased with the result.