The Factory will be an ultra-flexible space, hosting large-scale artistic work of invention and ambition, not easily found anywhere else. Dance, theatre, music, opera, visual arts, popular culture, and innovative contemporary work, will be showcased incorporating the latest digital technologies.

The project’s name, in part, is a nod to Manchester’s Factory Records, a legendary label responsible for the birth of the "Madchester" scene in the 1980s, with bands such as Joy Division, New Order and the Happy Mondays and also a hotbed of artistic talent such as Peter Saville. The record label was run by Tony Wilson, who was also a presenter on the North West’s Granada TV channel, which happens to be the site of this new development. The Factory will be built on the site of the old Granada TV studios.

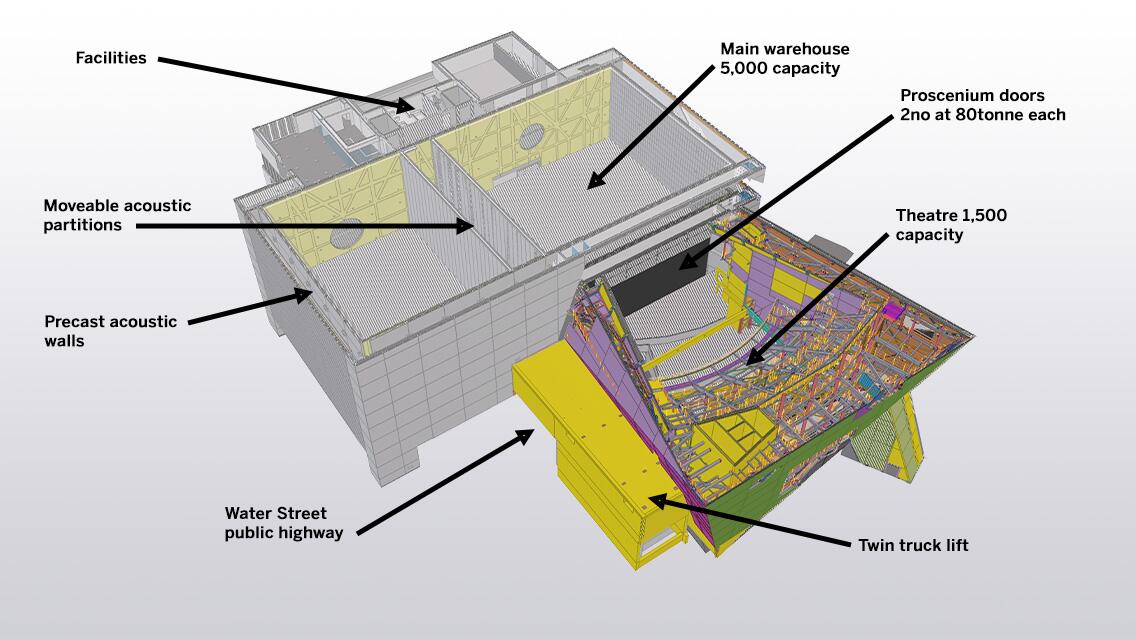

The Factory has been designed with flexibility in mind, and consists of two parts known as the warehouse and the theatre, both of which have moveable partitions and are acoustically-isolated, so they can be used individually or as one large area. The theatre has a 1,500 - 2,100 people capacity depending on its set up, and the warehouse will be able to accommodate 5,000 standing people.

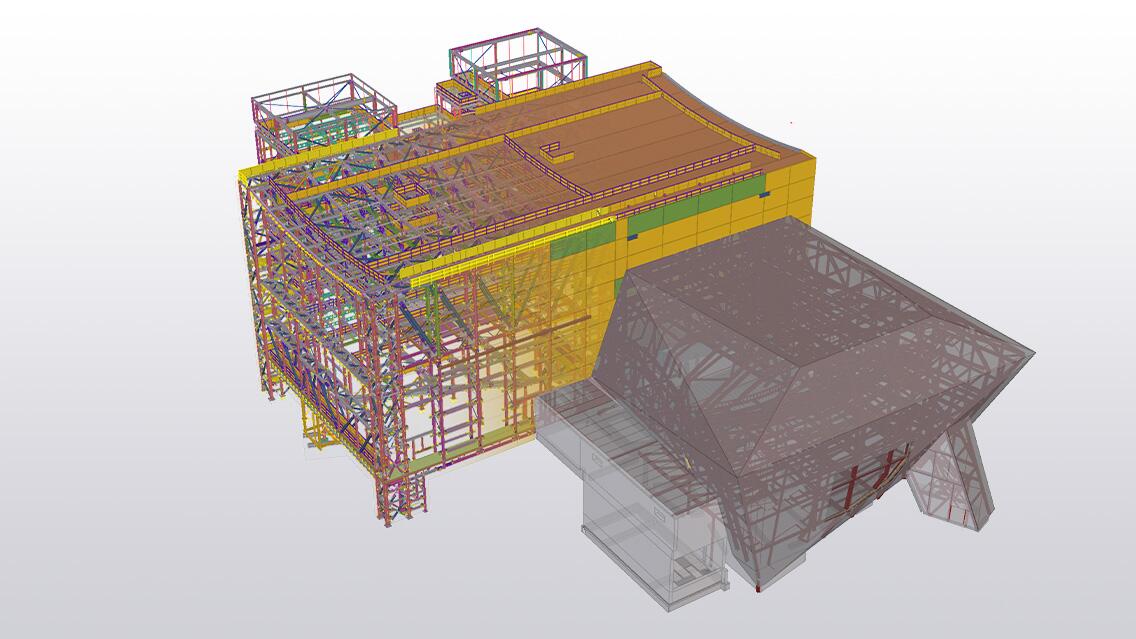

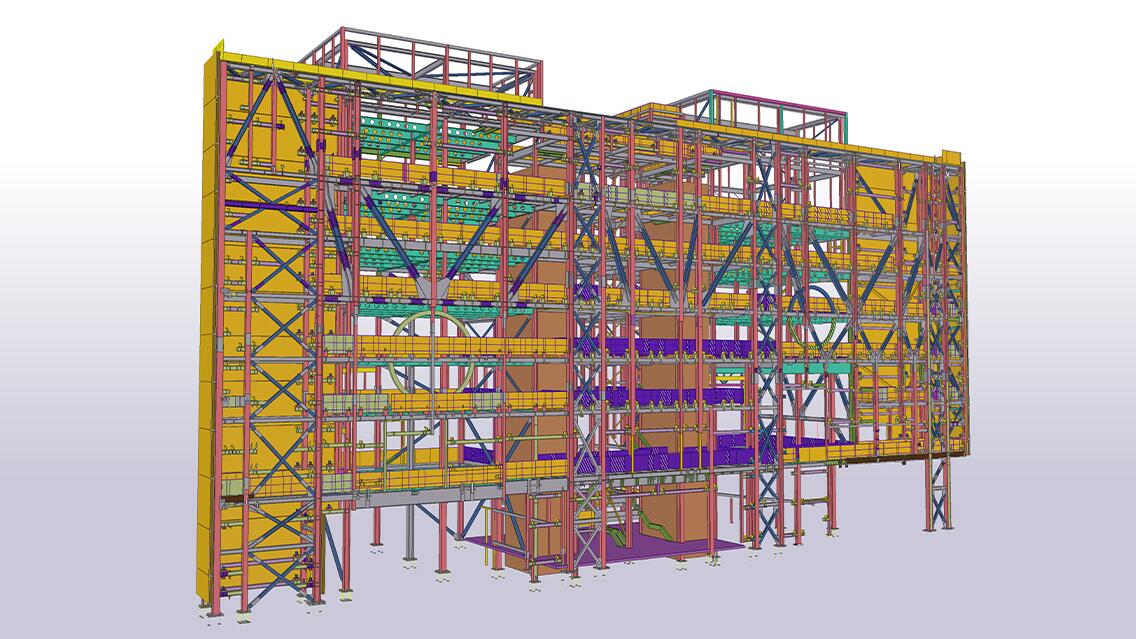

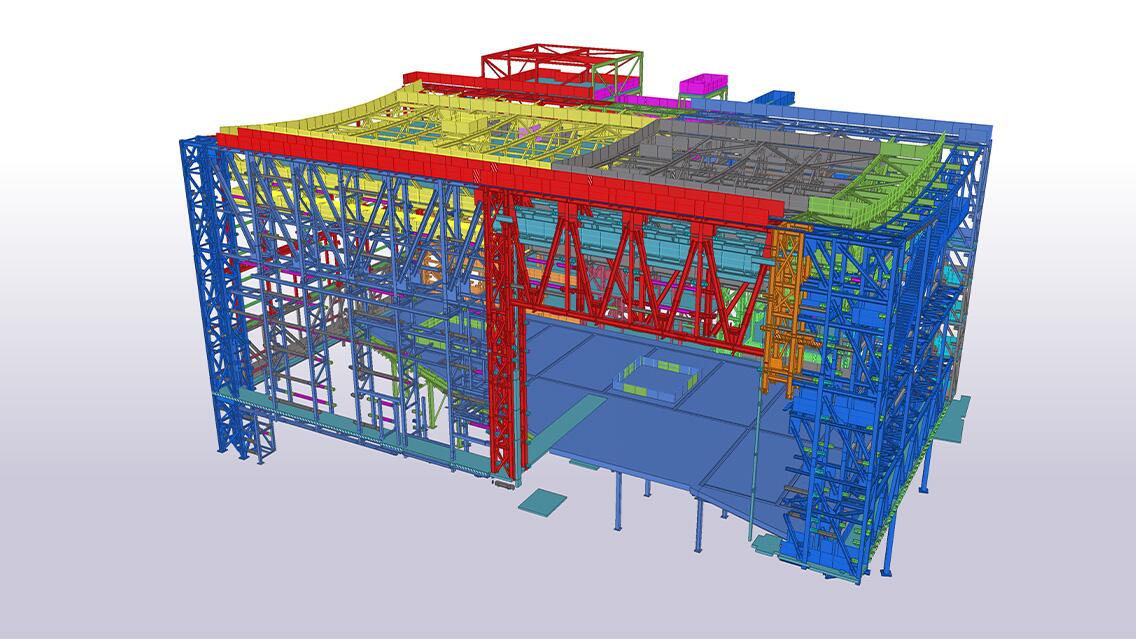

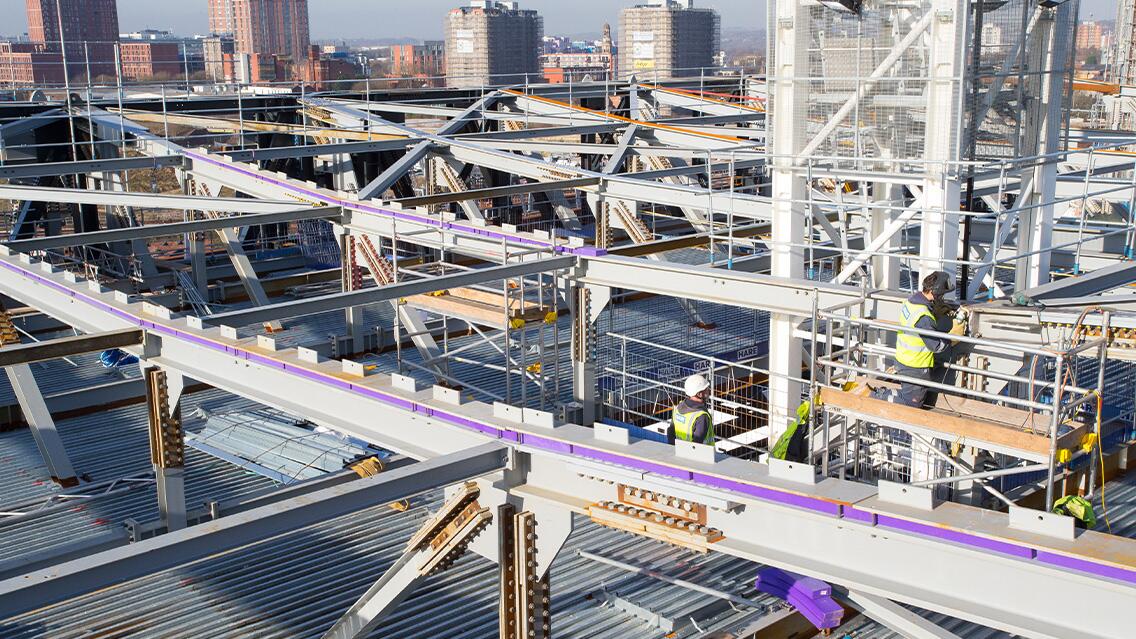

Steel construction has come to the fore with the erection of interlinked trusses, mega-columns, and numerous long-span plate girders, all of which form a new cultural building on a constrained inner-city site in Manchester.

Box-in-a-box design

As well as creating the box-in-a-box design, structural steelwork has formed trusses and transfer structures that help the building bridge over a number of site constraints – Water Street being one – and create the necessary column-free venue spaces. One of the most challenging parts of the steel frame is known as the West mega wall, that spans over Water Street, separating the warehouse from the theatre, it contains the connecting proscenium arch.

Tekla software had a significant benefit in allowing collaboration on the project. Concrete panels form the façade of the structure, each panel is individually acoustically isolated. We were responsible for the coordination of the steel, acoustic bearing, and precast interface. Due to the complexity of the structure, locating and agreeing support points became an challenging process involving, Buro Façade, Explore, and Farrats – 3D modelling had a valuable role in this.

Important points or benefits:

- Concrete panels form the façade of the structure, each panel is individually acoustically isolated. We were responsible for the co-ordination of the steel, acoustic bearing, and precast interface.

- Data generated via Tekla was used for all the regular cutting, drilling, profiling, etc. In addition Tekla-derived data was used with the Zeman robotic fabrication system; during Total Station surveying of assemblies during fabrication; in scribing systems; and extracting & manipulating data to manage changes to fab data.

- Trimble Connect was used extensively for collaboration and communication with the client, the designers, and our Wiliam Hare team. In addition to viewing information, the Trimble Connect platform was used extensively for tasks such as model and view sharing; model and drawing overlays; clash detection and BIM coordination; query resolution; task delegation; change management; report generation; data extraction; and more.