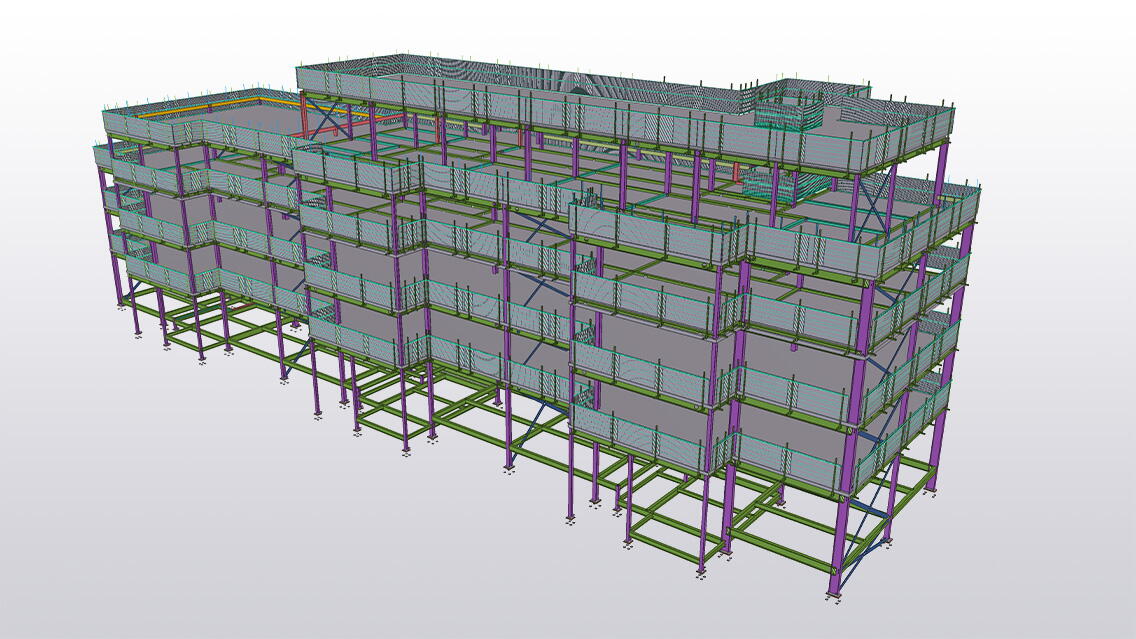

Double Check Engineering Ltd has integrated the Tekla-Grasshopper Live link into its operations, identifying instances of repeatable and reusable design elements.

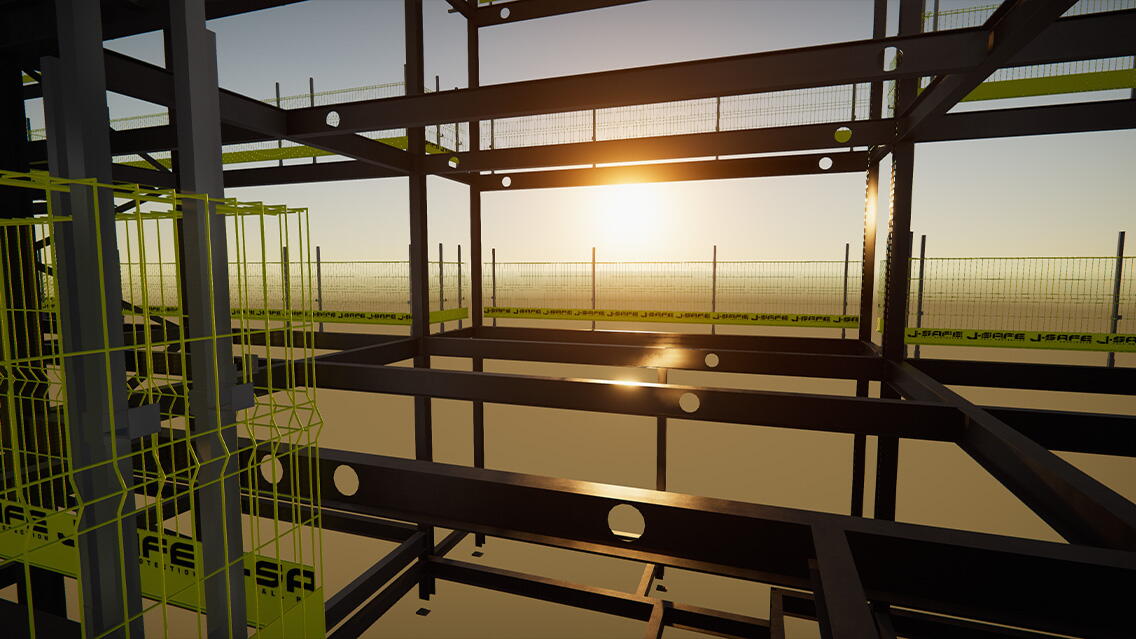

This project stemmed from a realisation that the application of specific rules governing edge protection could be streamlined through coding. A demonstration was initiated and communication was established with J-Safe, a specialist edge protection hire company reliant on detailers for its system implementation.

This project, conceived by Double Check Engineering Ltd, was refined through collaboration with J-Safe Edge Protection Hire. Their joint efforts have culminated in the successful implementation of this system across multiple projects to date, and is reusable for any location.

Challenges and achievements

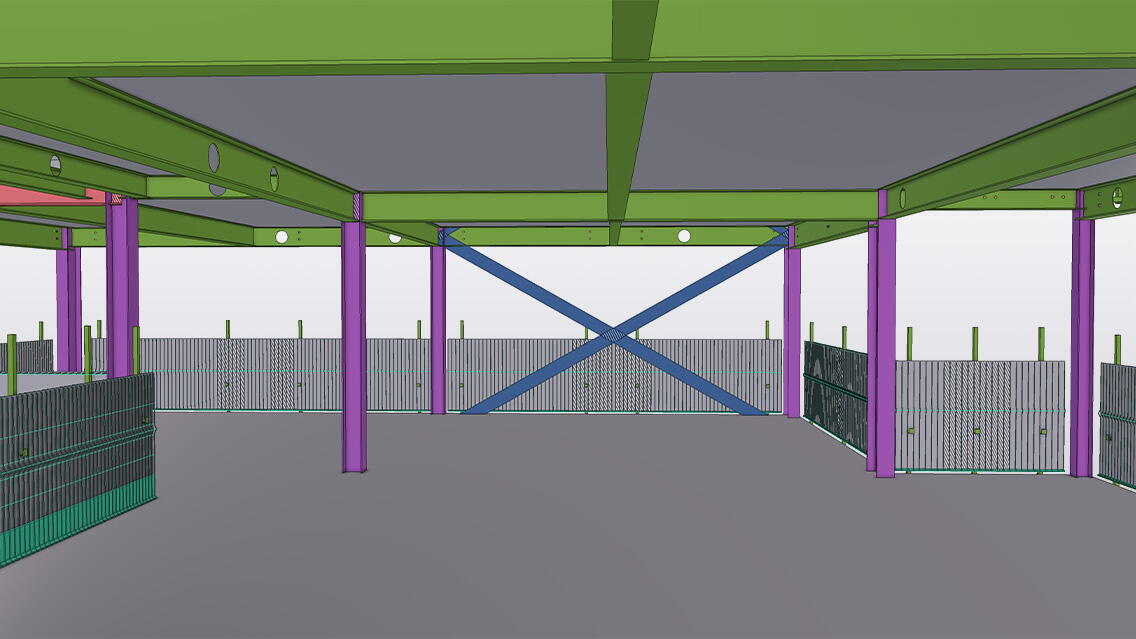

Initially perceived as a straightforward script, Double Check Engineering Ltd recognised the need to create a versatile script capable of being adapted to different architectural configurations.

Given that the building models are provided by external sources, the team had to make the orientation of the system not reliant on the orientation of the beams to which it was applied.

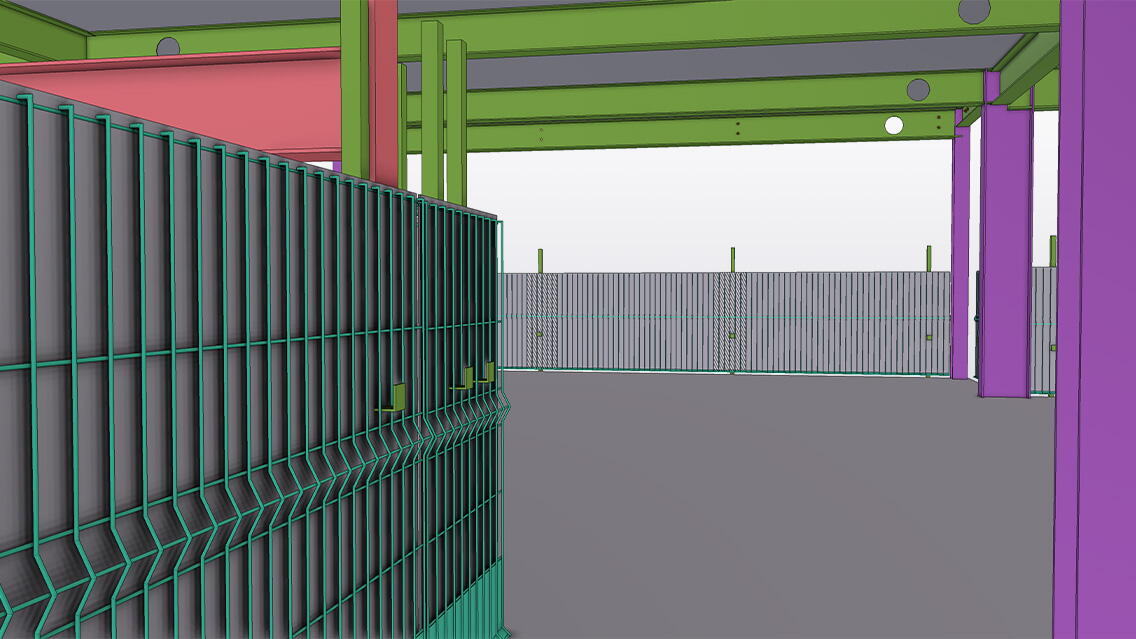

The streamlined process significantly reduces detailing time from several weeks to mere days for application, verification, approval, and issuance. This not only enhances productivity for Double Check Engineering Ltd clients but also alleviates bottlenecks within their workflow, thereby increasing their operational capacity. This increase in speed has also removed the need for job overlapping.

Using Tekla software

- Custom components were used to create the bolt groups and to model the mesh panelling.

- Double Check Engineering Ltd utilised code within a UDA to tell the script how to apply the system to different beams, sizes, and orientations.

- All approval has been undertaken via Trimble Connect.