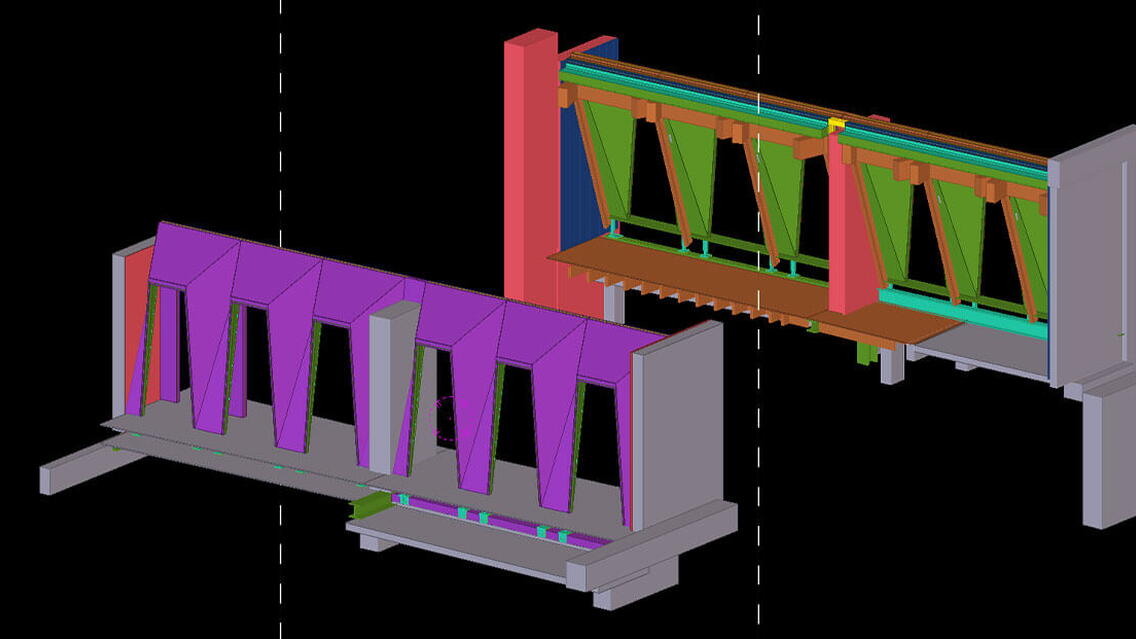

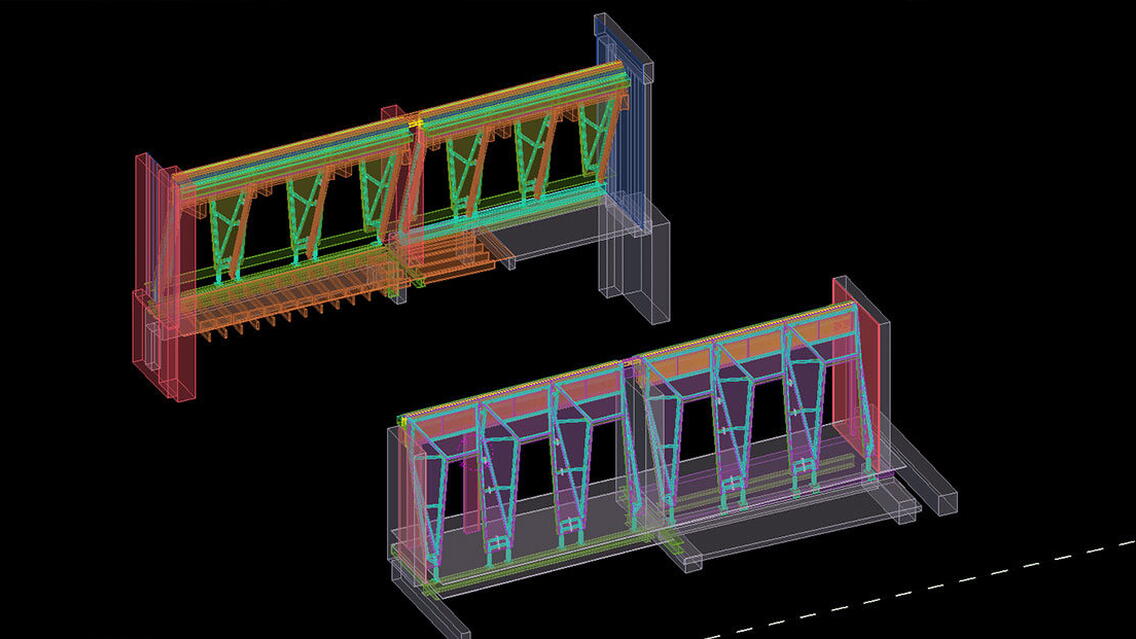

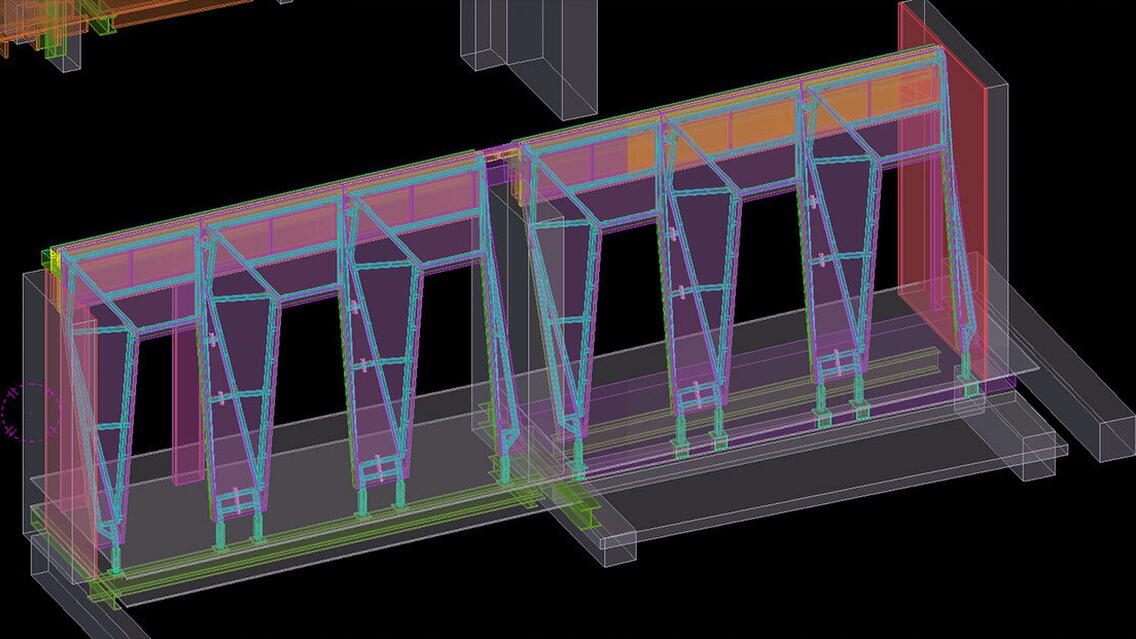

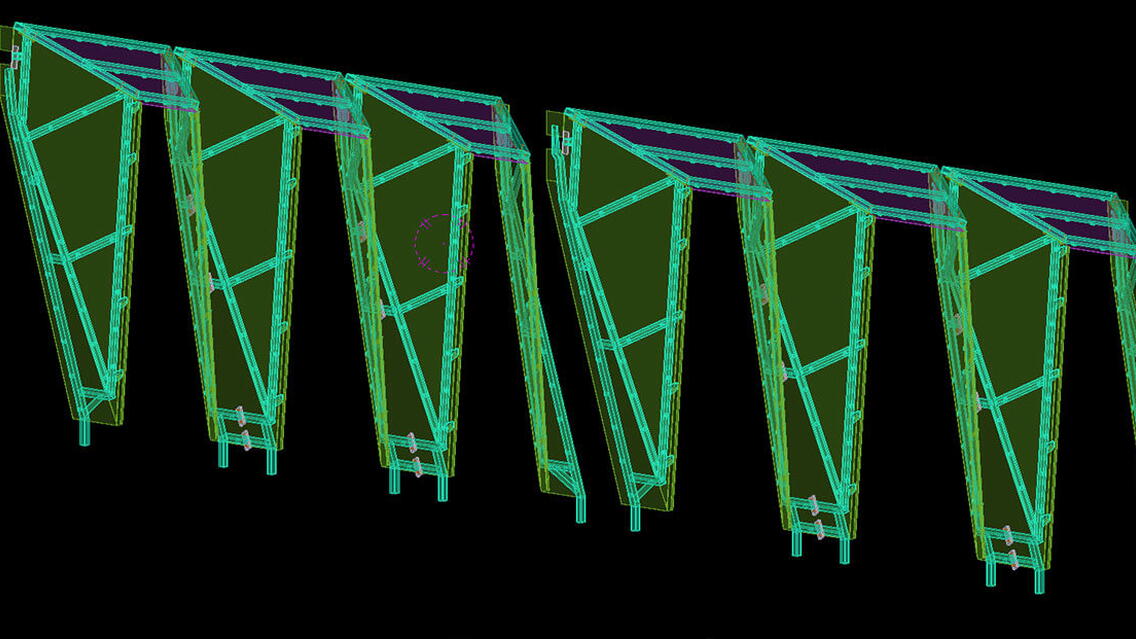

To design a folded metal roof/cladding for 12no. openings. Each got different opening size-wise; therefore, the design was not typical. This consist of a metal frame, a 5mm plate for the external cladding, a 3mm perforated sheet for the internal and a fascia support.

The project was started middle of the year 2020. We faced uncertainties throughout the design process and came to finish by end of 2020.

The cladding plates were very light, and any welding would cause major distortion to the plates, so we had to come up with a way of attaching the plates to the steel structure without welding brackets to the plates and it worked.

We always had to keep in mind Architectural intention as it was not straight forward. So, we had to then propose different types of design solution and come to an arrangement which can work for both requirement and British standard.

What were the challenges and what made the project successful?

The cladding plates were very light, and any welding would cause major distortion to the plates, so we had to come up with a way of attaching the plates to the steel structure without welding brackets to the plates and it worked.

We always had to keep in mind about Architectural intention as it was not straight forward. So, we had to then propose different types of design solution and come to an arrangement which can work for both requirement and British standard.

The project in numbers

- Total cost of the project: £340,000.00

- Steel Tonnage: 35 T