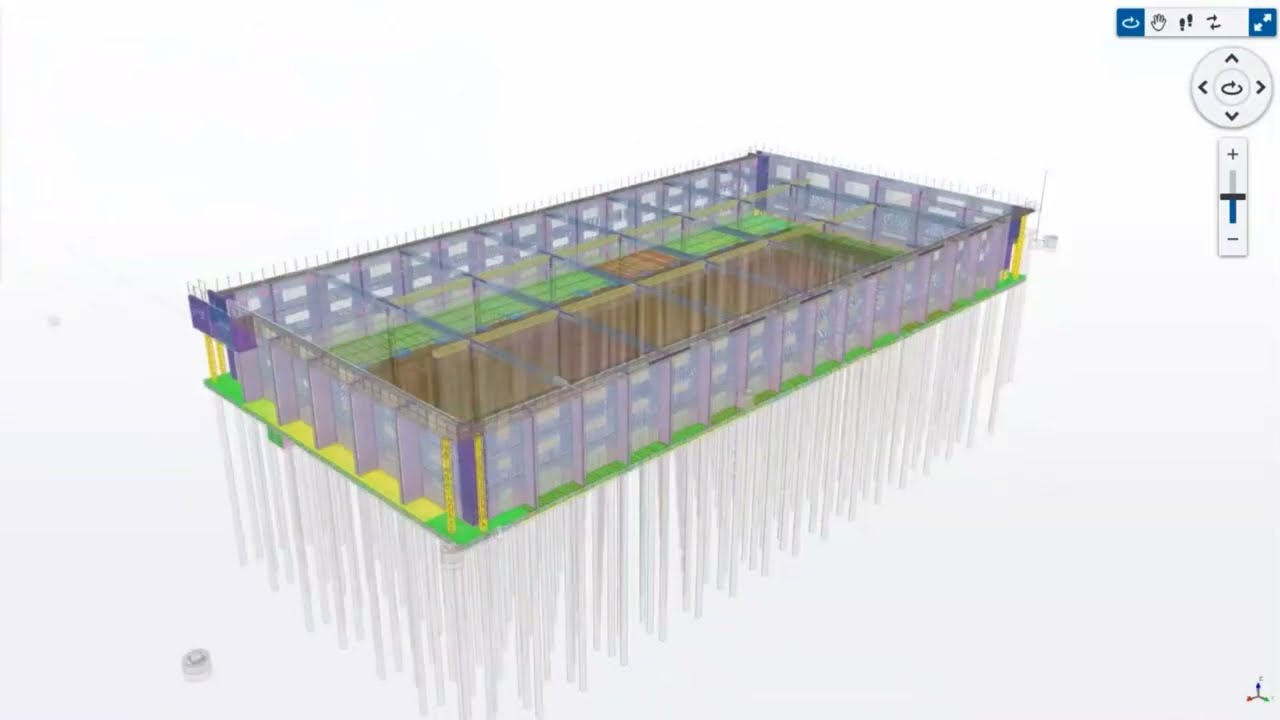

This project consists of a £123 million upgrade of the existing Beckton sewage treatment works, the largest in Europe. The first works were built in 1864 by Sir Joseph Bazalgette.

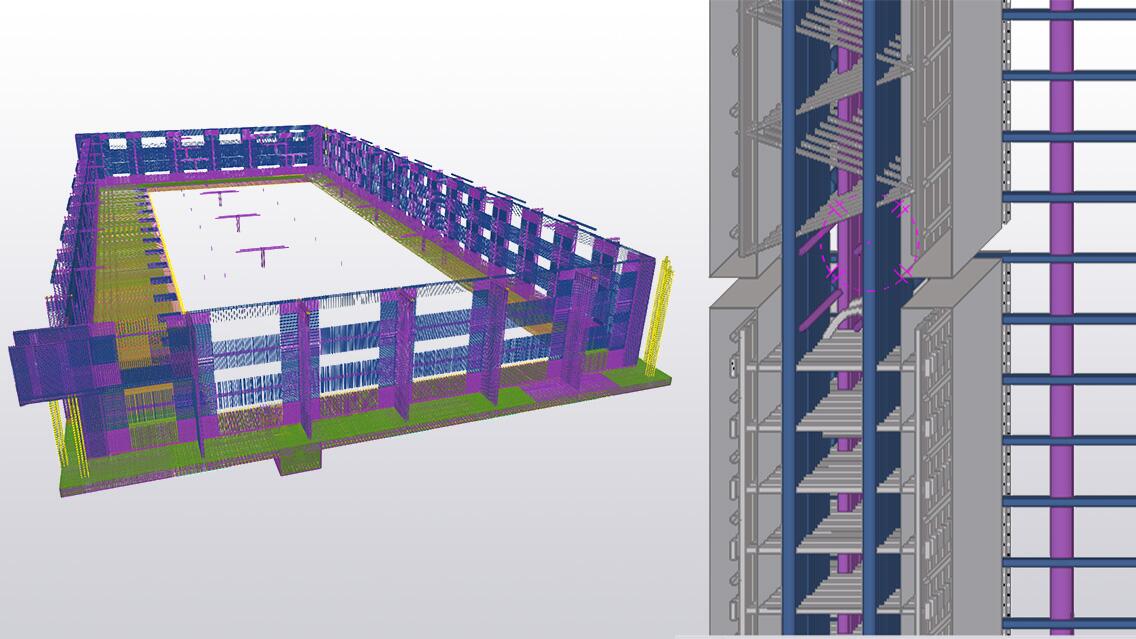

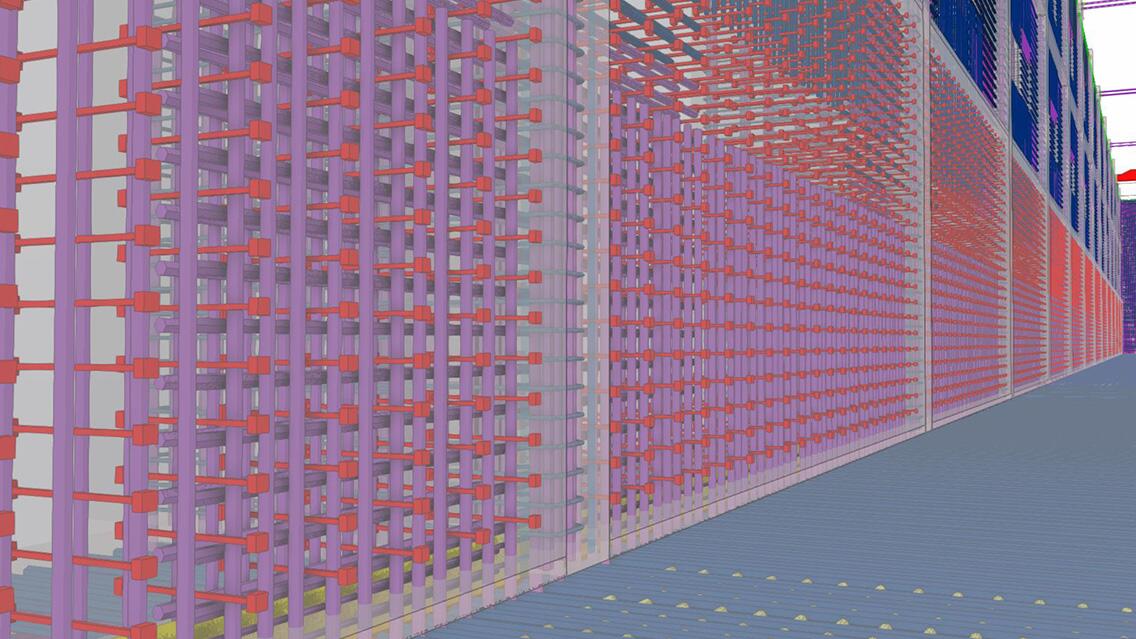

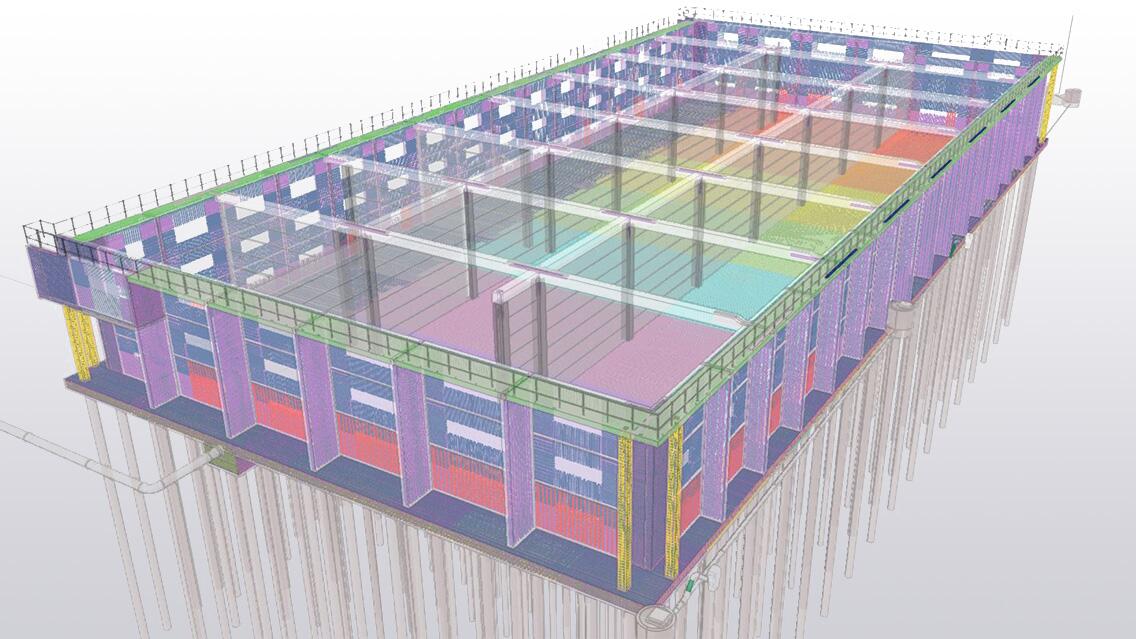

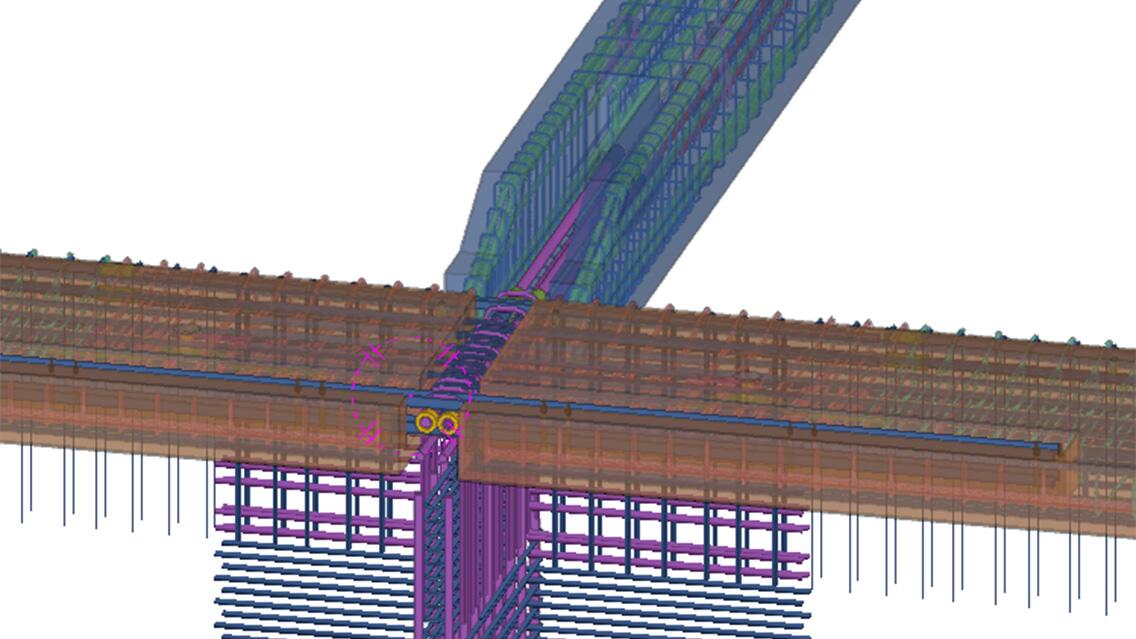

To increase the capacity and cope with London's growing population, a number of buildings and structures were delivered by Laing O' Rourke and Atkins across the site, including two aeration lanes (21 & 22), four settlement tanks and a completely new inlet works. Both Laing's and Atkins were keen to maximise the use of digital engineering and off-site manufacture to enable DfMA. This digital drive culminated with the successful installation of over 380 twin wall systems fabricated off site for the aeration lanes 21/22, which is now to going to be used on future sewage treatment works, such as Guildford, given its huge benefits in cost, time, and efficiency.

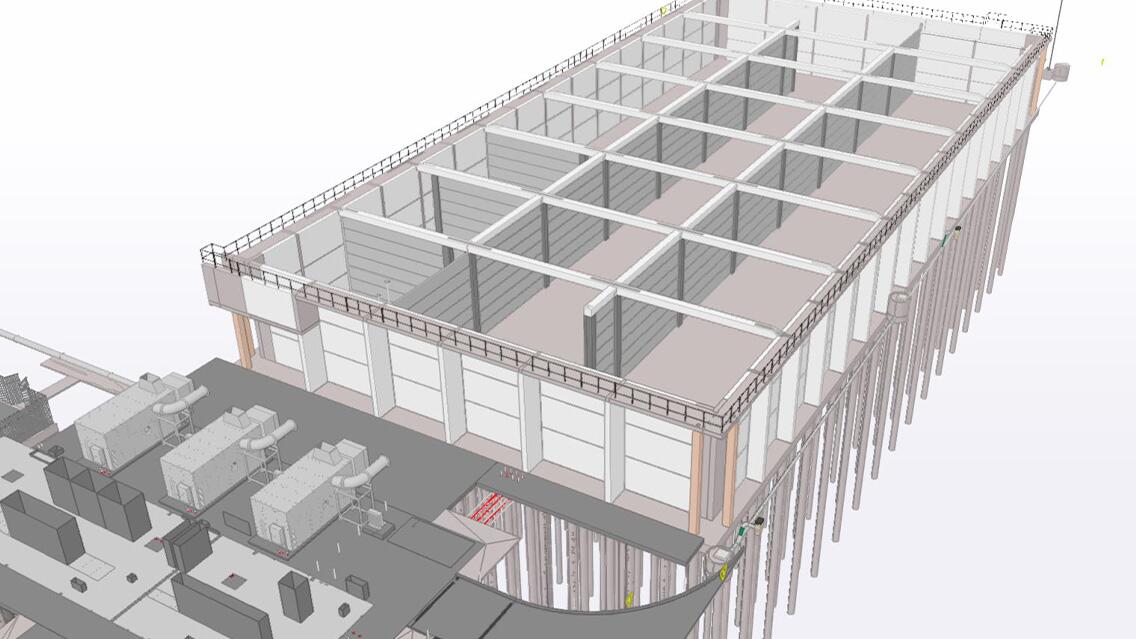

Off-site fabrication for maximum efficiency

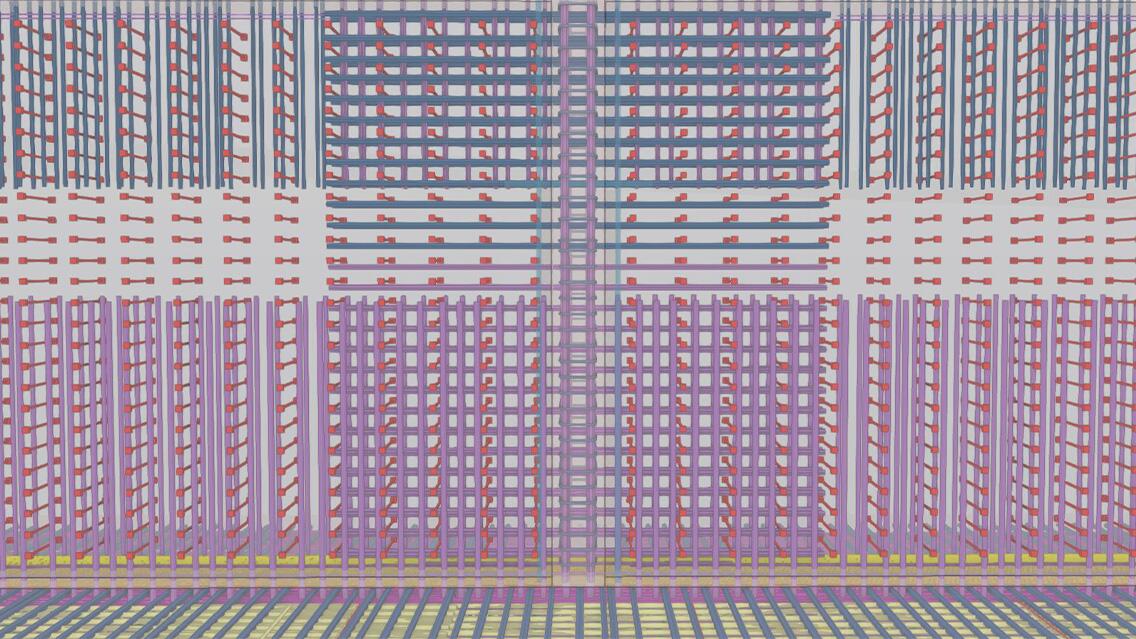

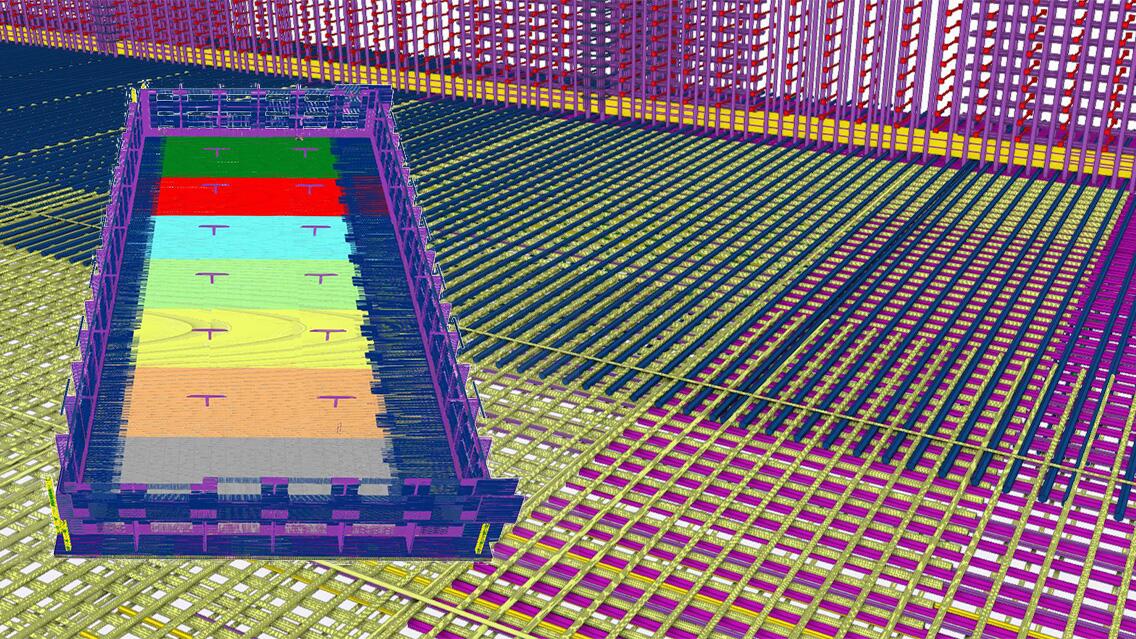

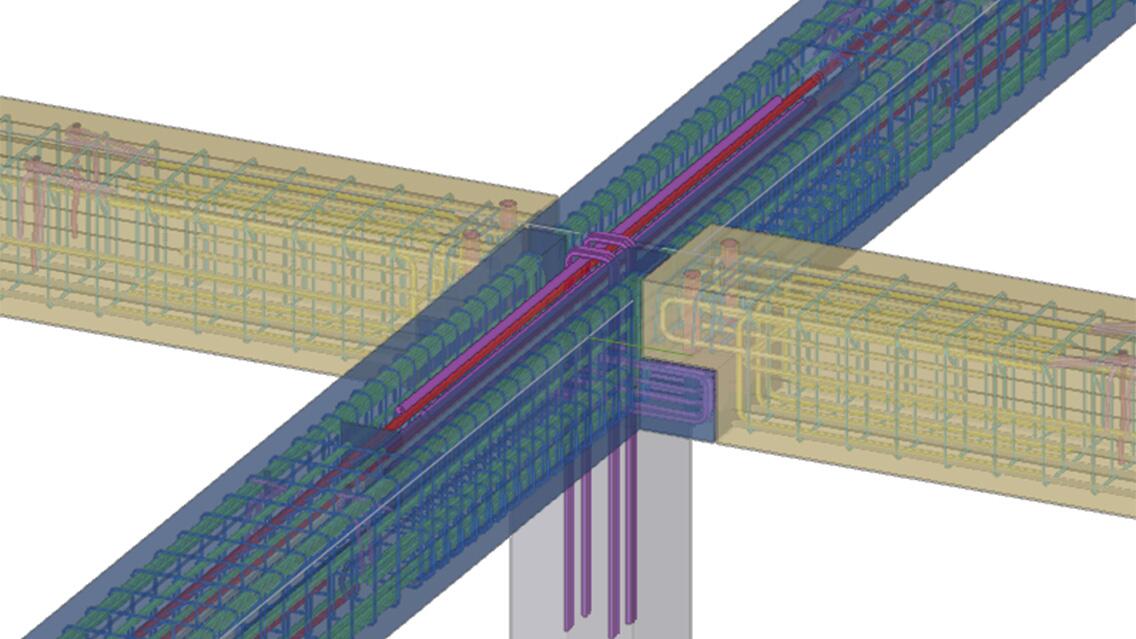

The biggest challenge of Lane 21/22 was the large amount of interfaces that required coordination (Roll matt systems, pre-cast elements, beams, columns, twin-wall systems, raft and wall 3D reinforced concrete models, walk-way elements and complex geometry) due to the promotion of DfMA across Beckton. Using Trimble Connect and Tekla software, we were able to successfully federate and understand all interfaces. Allowing off-site fabricated elements, such as the 191 no. twin wall systems, to be installed with maximum efficiency to ensure DfMA benefits were realised.

As a result of this, the short construction time for the building is the resounding success of this project. Some of the key benefits realised during this construction and utilised across Beckton are listed below:

- Successful replication of Lane 21 building utilising Tekla for Lane 22, saving cost, time, and standardising construction methods.

- Utilisation of 3D RC models on site by Laing O' Rourke and manufacturers for all works, promoting digital engineering, Tekla and paperless construction.

- Utilisation of Trimble Connect and Tekla allowed successful contributions from Atkins India Office, enabling easy communication during QA and design process.

Important points or benefits:

- Building dimensions: L=85.2m, W=41.1m H =9.15m

- Piles - Number of bars: 56619

- Weight of bars: 413,4 tonnes

- Volume of concrete: 2728m3

- Volume of pre-cast concrete: 1390m3

- Number of pre-cast elements: 62

- Number of Twin wall systems: 91

- Couplers (headed, transition, standard): 1147 no.

- Non-standard shape codes utilised: 8 no.

- Time to produce Lane 22 due to replication: 5 days