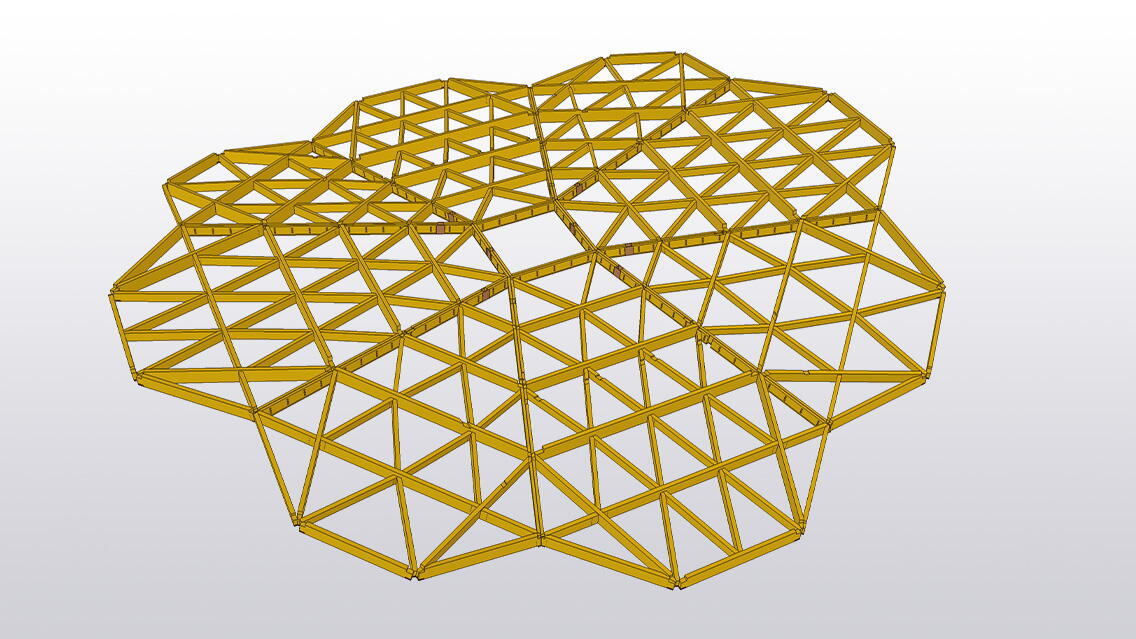

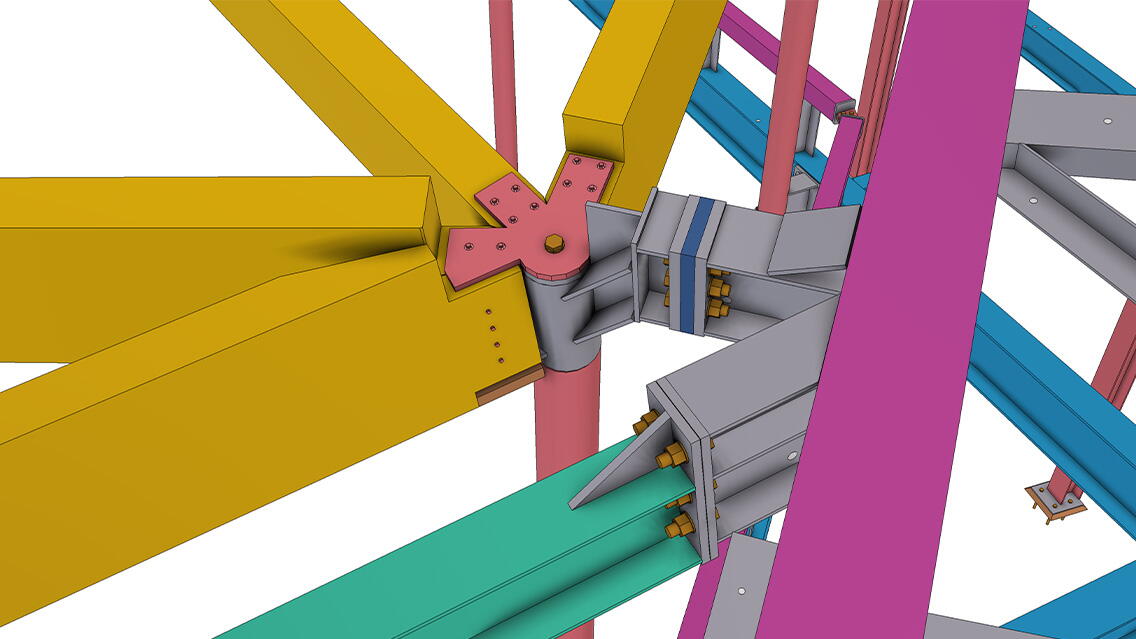

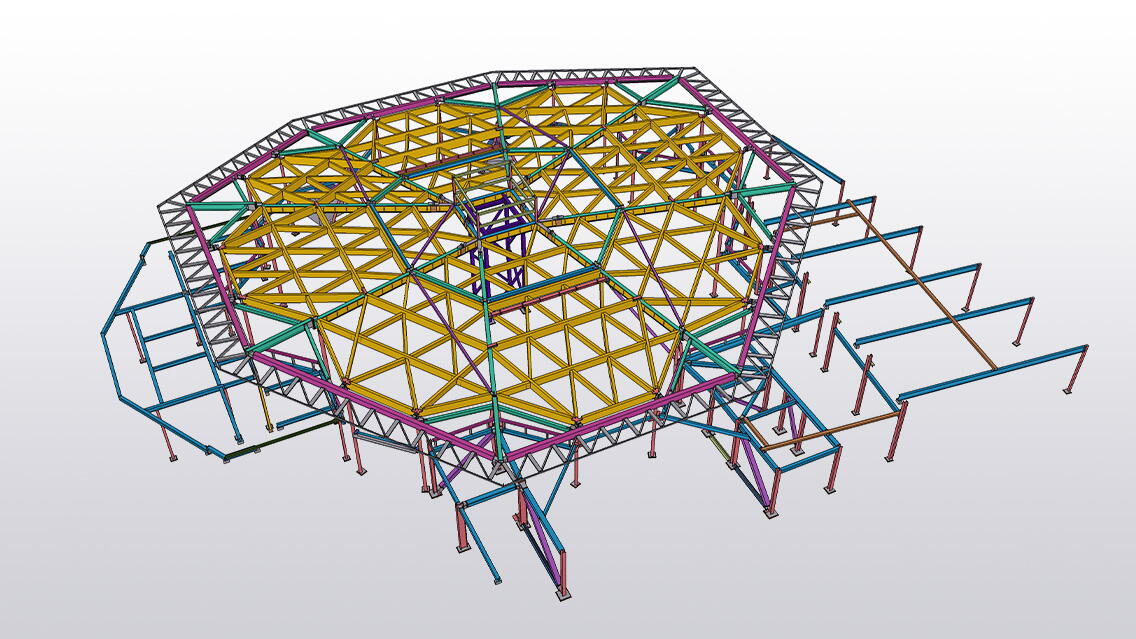

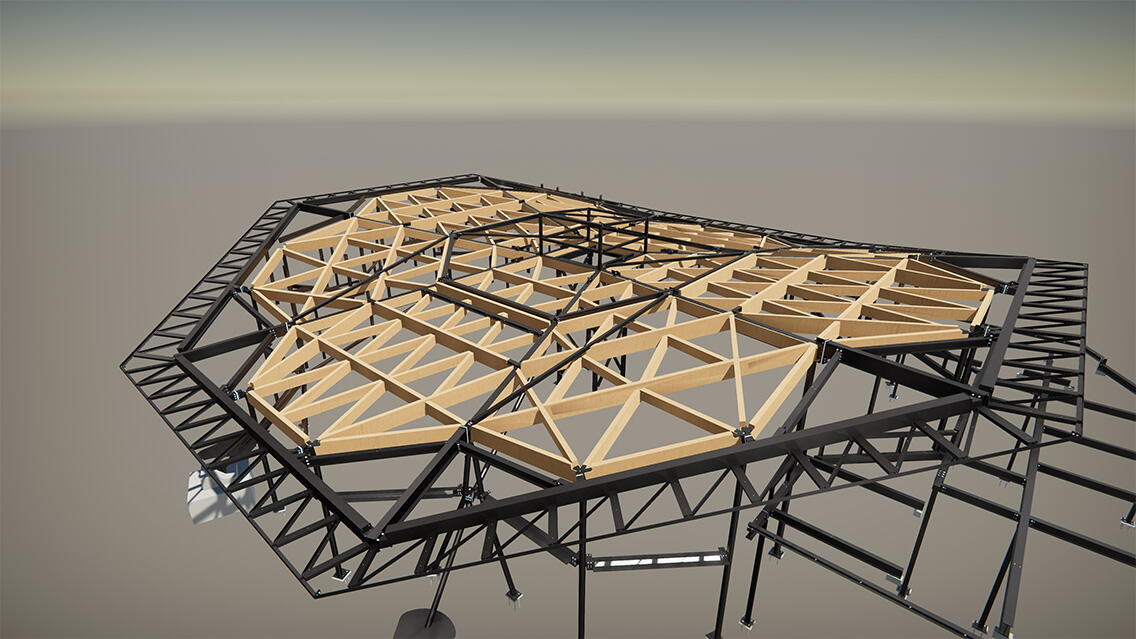

Beech Court Pavilion at Abingdon School is a stunning new catering and hospitality space, designed to be a new hub for school life and enhance the student experience. Developed to integrate the existing school and theatre, the Pavilion is a striking timber structure. It features a complex steel canopy frame and feature glulam diagrid roof, utilising innovative connection design and close collaboration from the detailing to the manufacturing stages to create the unique geometry of the exposed timber and structural elements.

Challenging fabrication, design and erection of the major trusses and diagrid roof required thorough planning and collaboration from start to finish. Key consideration was given to the tight site access and maintaining a live construction site during term time which was overcome through careful planning and an innovative logistics plan. The canopy was delivered on site in only 8 weeks. A key driver for the client was designing the pavilion to maintain a connection to the outside landscape, and as such exposed structural timber was an ideal solution.

The use of a feature glulam diagrid roof ensured students benefit from the biophilic qualities of the natural materials, and the pavilion has green views in all directions. The space has been designed to facilitate changing functions throughout the day, acting as a dining room, a café, a study space and even a theatre spill out area. It also includes a sedum roof, raised beds and a tree lined approach which allows the pavilion to fit sensitively into the landscape within a garden setting. Overall, the new dining pavilion at Abingdon School is a contemporary and dynamic space which exemplifies the striking contribution timber construction can bring to the education sector.

Challenges and achievements

The design of the roof structure was particularly intricate and complex, requiring close attention from the B&K Hybrid Solutions drawing office to the setting-out, the individuality of the connections and aesthetic requirements from the client. This required close coordination from all parties - including follow-on trades and other subcontractors – to achieve the tight site programmes, further restricted due to the building’s location on an active school site. Trimble Connect was used in the workshop to view the 3D model during the fabrication process, and to visualise the complex fabrication for the ‘3-legged’ columns. This ensured a successful assembly of these members which otherwise would have been difficult to show on 2D drawings.

The design required a central support tower that could be removed when the building was complete, allowing the roof structure to be self-supporting on completion of the erection works. From a design perspective, the frame analysis needed to be accurate, with deflection of the roof - a critical item once fully complete. From a build perspective, the temporary works review of the installation method was equally challenging and required the roof to be built in quadrants before this temporary frame could be removed, to allow the roof structure to support itself. Challenges were well considered throughout the design stage, enabling a flawless onsite phase in which the structural works were completed in only eight weeks.

The final visual result at Abingdon Beech Court is the key point of pride for the whole B&K Hybrid Solutions project team: the exposed diagrid glulam roof is visually impressive and showcases the aesthetic benefits timber construction can bring to an education setting. From a drawing office perspective, the steel fabrication and glulam connections were particularly complex, and the accuracy of the final outcome is something to be proud of.

The collaboration of models between the architect, engineer and B&K Hybrid Solutions as specialist subcontractors meant that the production of drawings with plan dimensions and the setting-out of sloping members was not only achieved successfully, but vastly accelerated. Due to the complexity of the project, production of drawings from all parties would have been far more time-consuming without adopting the BIM route in developing the project. Tekla and collaboration with the client’s design team, using Trimble Connect and snapshots, allowed issues to be raised earlier and resolved more easily. The approval process also benefited from similar time advantages, given models could be passed numerous times between all parties in a relatively short space of time.

Using Tekla software

- To process the steel the B&K Hybrid Solutions team exported NC files from Tekla, which were then imported into Raptor programming software by the production department.

- The manufacturer of the Glulam was sent exported DXF files and IFC models of each lot, then used by the suppliers to manufacture the products.

What does B&K say about the project?

“The photos of Abingdon are fantastic, and have given all the draughtsmen who contributed a great sense of pride in seeing our modelling work come to life. The quality from all involved is evident and the building now looks immaculate, resembling a quality piece of furniture. Having used a number of modelling systems over the last 32 years, there is a reason that Tekla is the market leader in our industry. Incorporation of IFCs, DWGs and point cloud surveys are critical to projects such as Abingdon Beech Court, and Tekla allowed this to be achieved seamlessly”.

- Glyn Hubbard, Drawing Office at B&K Hybrid Solutions