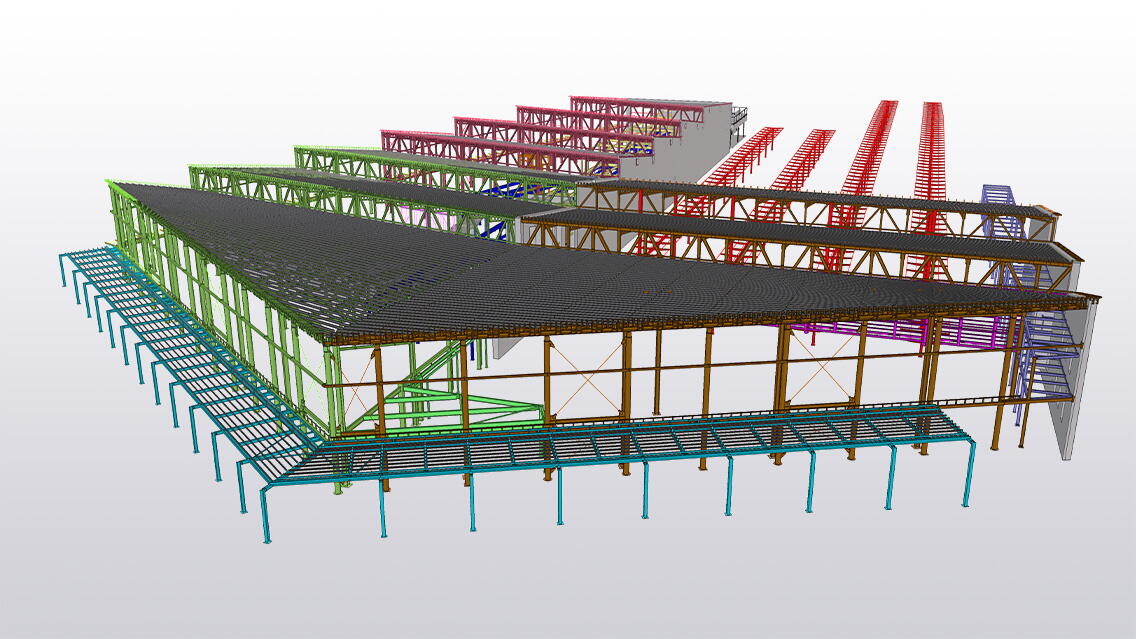

The Belfast Grand Central Station project is currently the largest infrastructure programme in Ireland, comprising a £200m Translink train and bus station and is situated in the centre of Belfast.

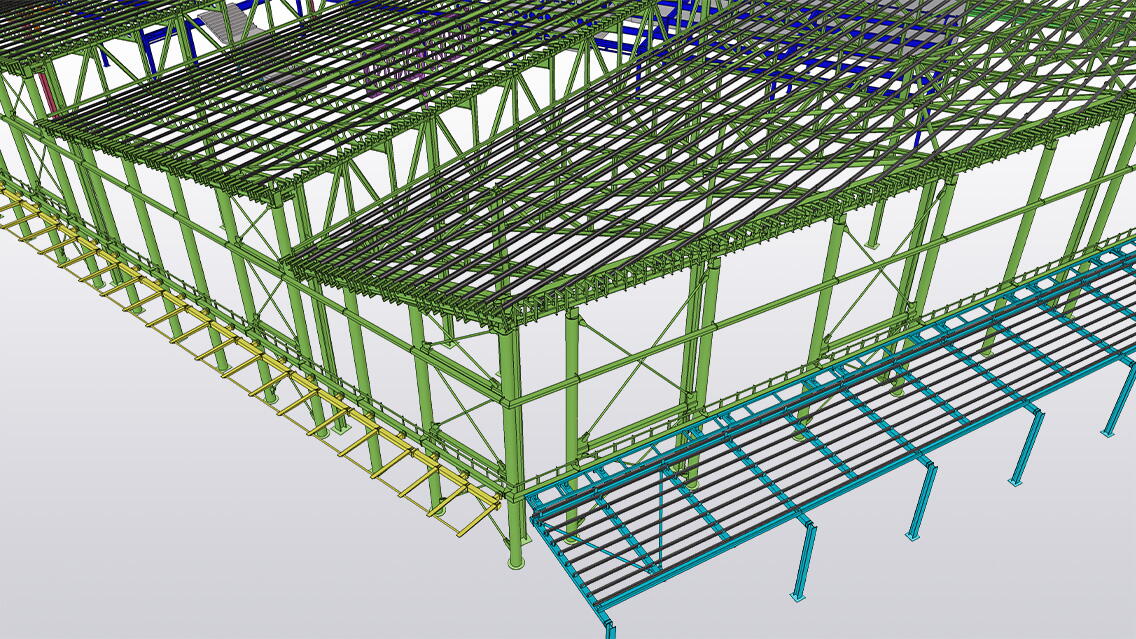

Walter Watson Ltd was the steelwork subcontractor for Farrans Sacyr on this project; they fabricated, delivered and erected the full structural steel package, including hot-rolled and cold-rolled steelwork. Arrangement drawings, fabrication drawings and full erection drawings were detailed using the Tekla 3D model.

Challenges and achievements

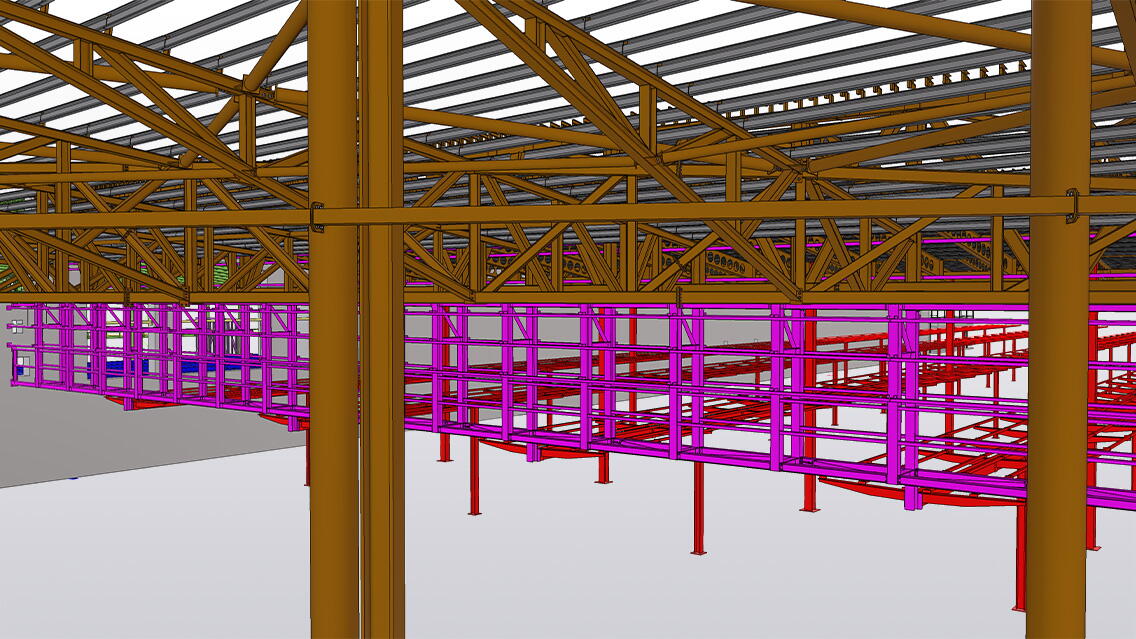

The main roofs of the Belfast Grand Central Station sloped in two directions, as well as being curved to form sloping bowl effects. The subsequent challenge to connect straight purlins to these curved roofs was made possible through sharing IFCs between the Senior Draughtsman and the design team within Walter Watson Ltd.

Tekla was used throughout both the preconstruction and construction processes, importing IFCs and DWGs from the main contractor and other trades respectively to ensure that all works were coordinated accurately on site. Using the DSTV export feature, NC files were generated and sent for cutting and drilling the steel members and fittings, ensuring accuracy directly from the 3D model.

Using Tekla software

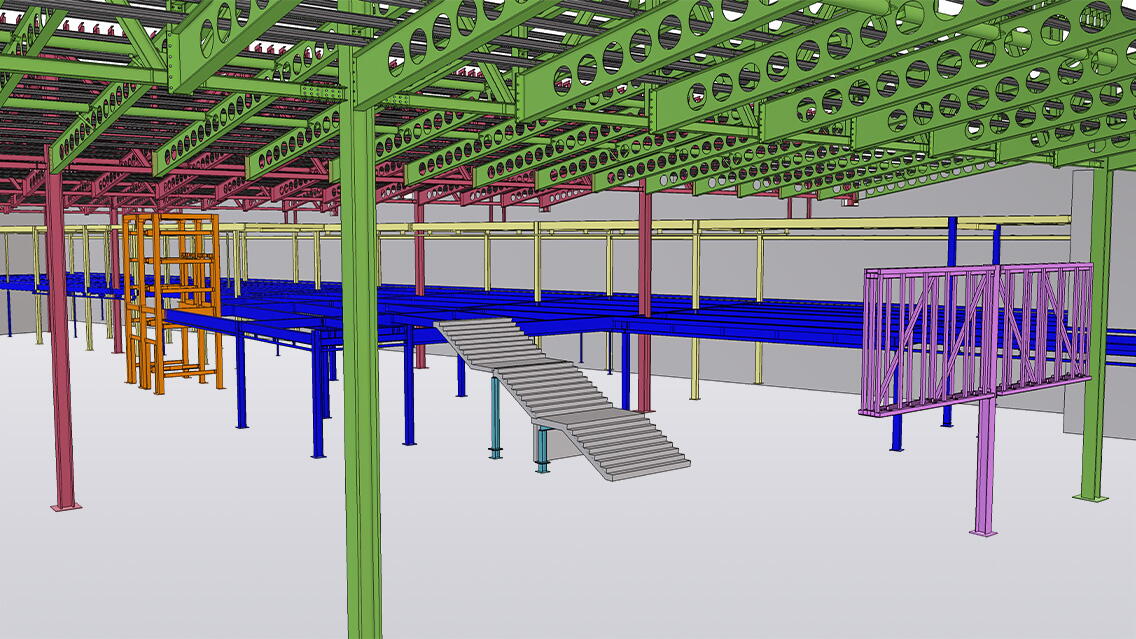

- IFCs were received from the Main Contractor, and DWGs were received from other trades to be imported into the 3D Tekla model for coordination.

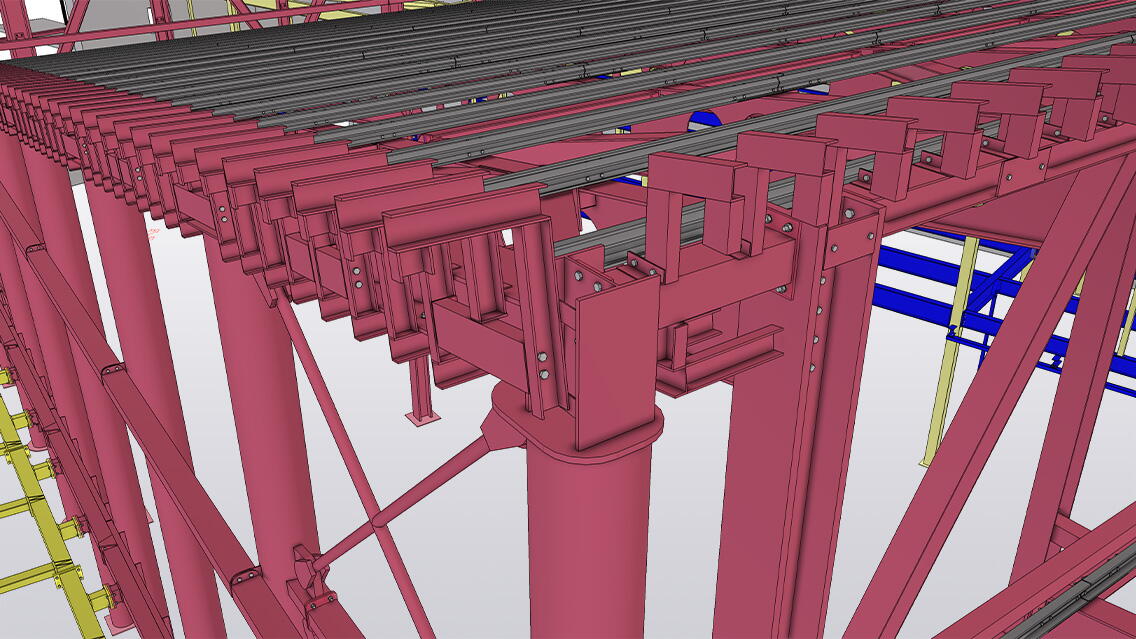

- Custom components were used for a lot of non-standard but repetitive connections.

- UDA fields were used for filtering views and drawings to convey the exact information required by Walter Watson Ltd’s pricing, fabrication and erection departments and also produce information to the design team for approval and coordination purposes. By filtering the views using UDAs, Walter Watson Ltd draughtsmen could focus on specific areas of the model and produce IFCs and drawings.

- STRUMIS files were generated from the Tekla model for nesting the members.

- Updated IFCs were generated and issued to the main contractor for distribution to other trades, for coordination and discussions.

- NC files were generated using the DSTV export feature for cutting and drilling the steel members and fittings.

- Arrangement drawings were issued to the client in PDF and DWG format, which were all generated from Tekla software.

What does Walter Watson Ltd say about the project?

“Building a 3D model helps to get a better visualisation of the components in the structure and how they fit together. Once you're happy with the way they fit in the model you can produce fabrication drawings knowing that the members will fix together on site.”

- Kenny Sturman, Senior Draughtsman at Walter Watson Ltd