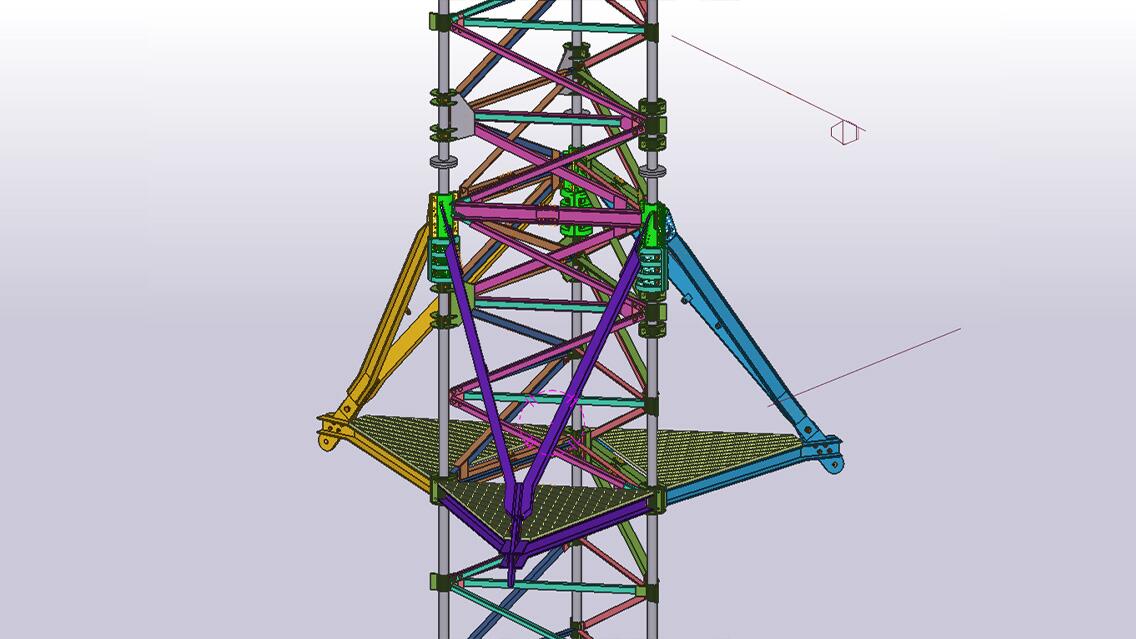

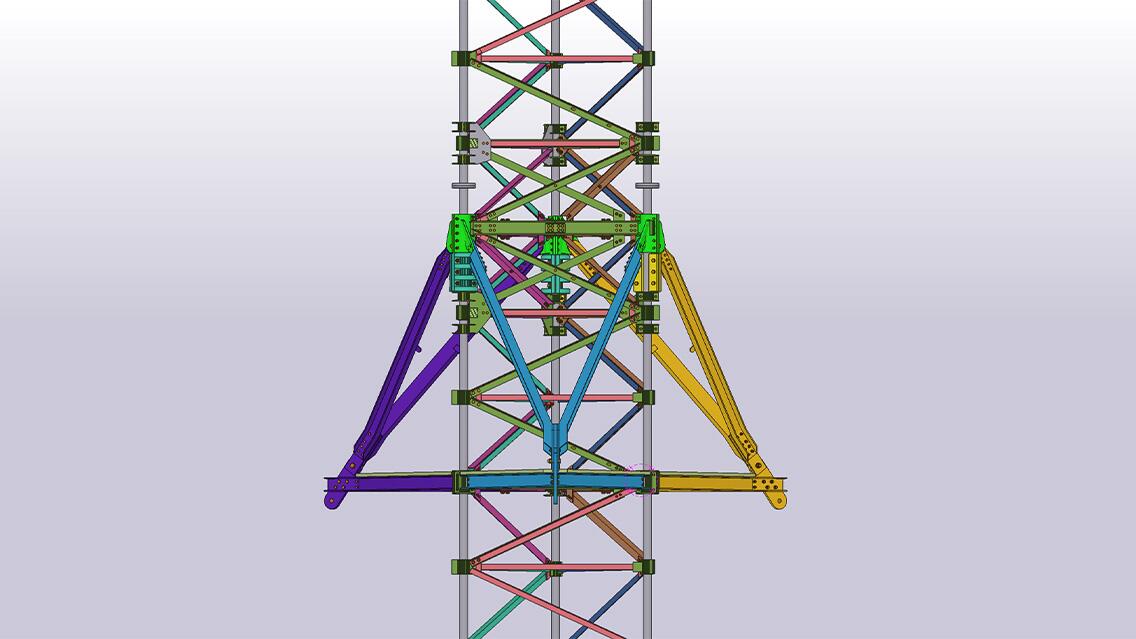

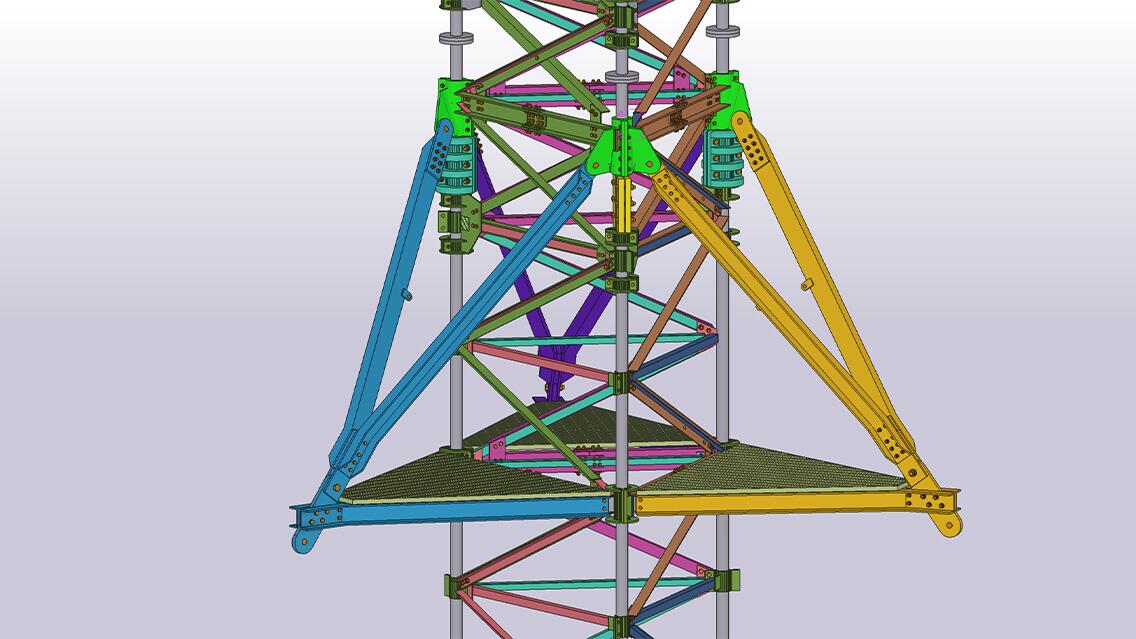

The stay landing was moved on the mast column to improve the bending moment in the mast.

On the new location, a fully triangulated frame has been used to avoid bending moments in the members which helped avoid the need for heavier sections and also to improve the ease of erection as well as improved transfer of the stay forces to the mast body. All stays on the mast are landing on stay frames because the stay lines are not aligned with the mast legs.

Overcoming work at great heights

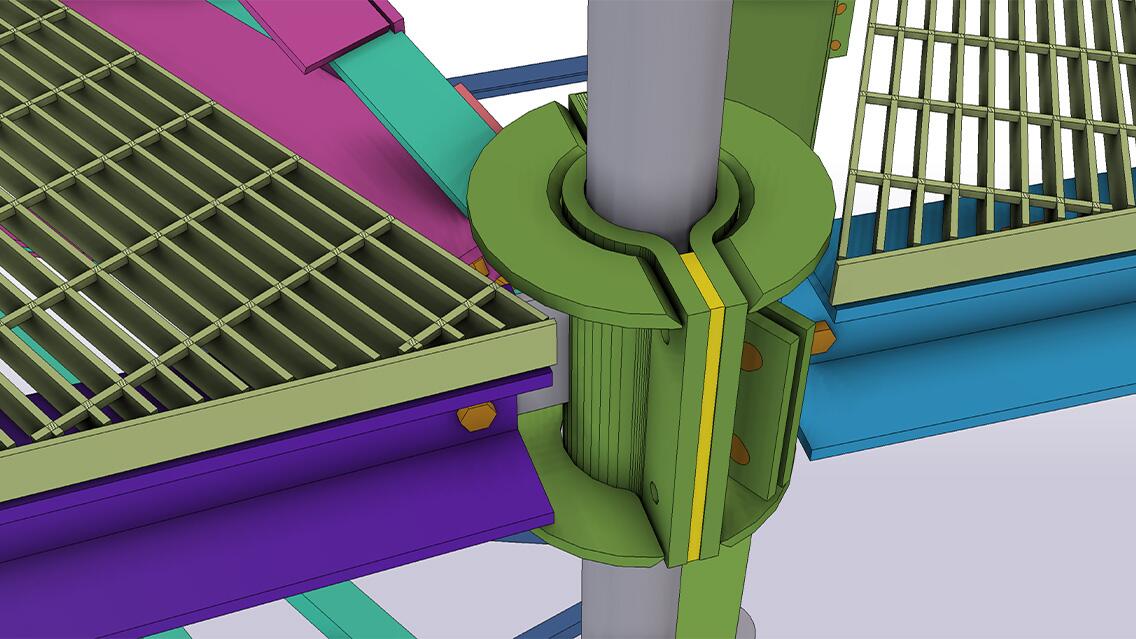

The client's design meant we had some very bespoke pieces to fabricate. Some required a casting because of their shape and parts welded to them to make the finished product. This was due to angles of the stay frame coming onto the new clamps on the legs, which resulted in the parts needing skewed bends. Using Tekla we were able to work out the exact skewed bend required and model accordingly to create a casting for a connecting plate to fit to attach to the new frame.

The design was clamp based so we had to create numerous bespoke welded parts containing small intricate bent pieces, which if we were using 2D software would have taken us weeks to figure out. Having a 3D model helped us save time detailing and enabled us to show the fabricator 3D models of the required castings so that they could create casts to create the parts from, which ensured we were right first time on fabrication.

Using our old imperial drawings from the 1950s we were able to model the existing mast which enabled us to model the new steel precisely and run accurate clash detections to ensure nothing could go wrong during the install as it was 184m above ground. We had to be right first time with everything as down time on Antenna Masts can mean outages for 4G,5G and broadcasts. It goes without saying that working at such heights takes a lot of planning and risks!

Important points or benefits:

- New frame: 184m above ground

- Cast items: 6

- Parts: 150

- Bolts: 480

- 4.7 tonnes of steel and bolts