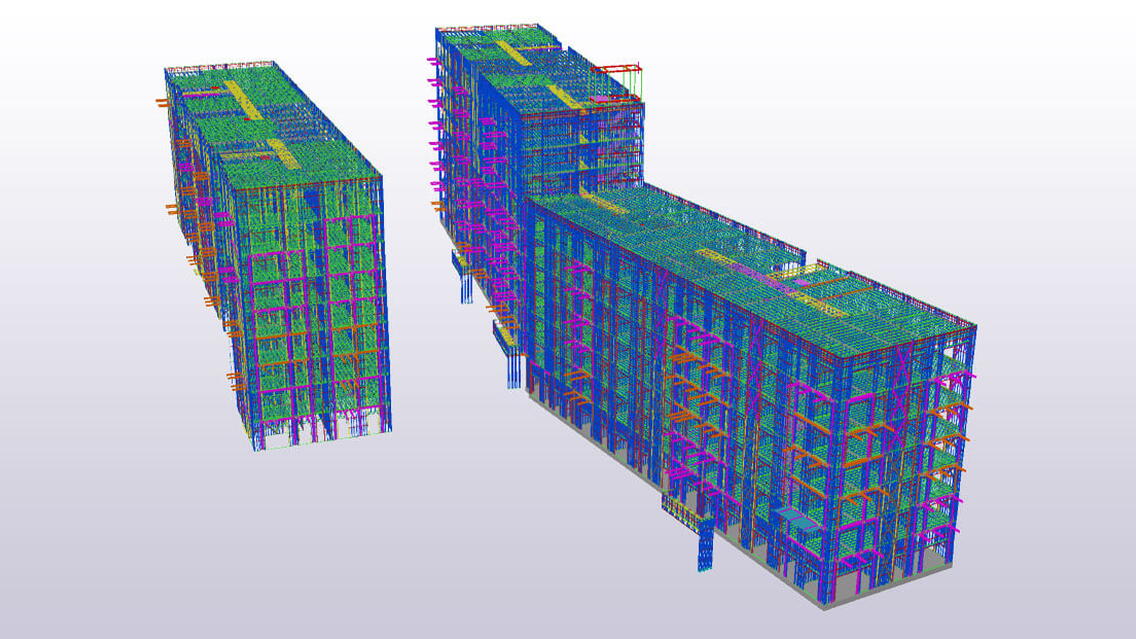

Brent House, the construction of 248 apartments and c.6,000 sq. ft of retail space, around a new landscaped public plaza.

This development is in partnership with Henley Homes and Notting Hill Genesis Housing Association and consists of demolition of the existing building (a former council office building sited in Brent between Wembley Stadium and Wembley High Road on a 1.9 acre site) and construction of 248 apartments and c.6,000 sq. ft of retail space, around a new landscaped public plaza. This development is finishing in phases from late 2019 to early 2020.

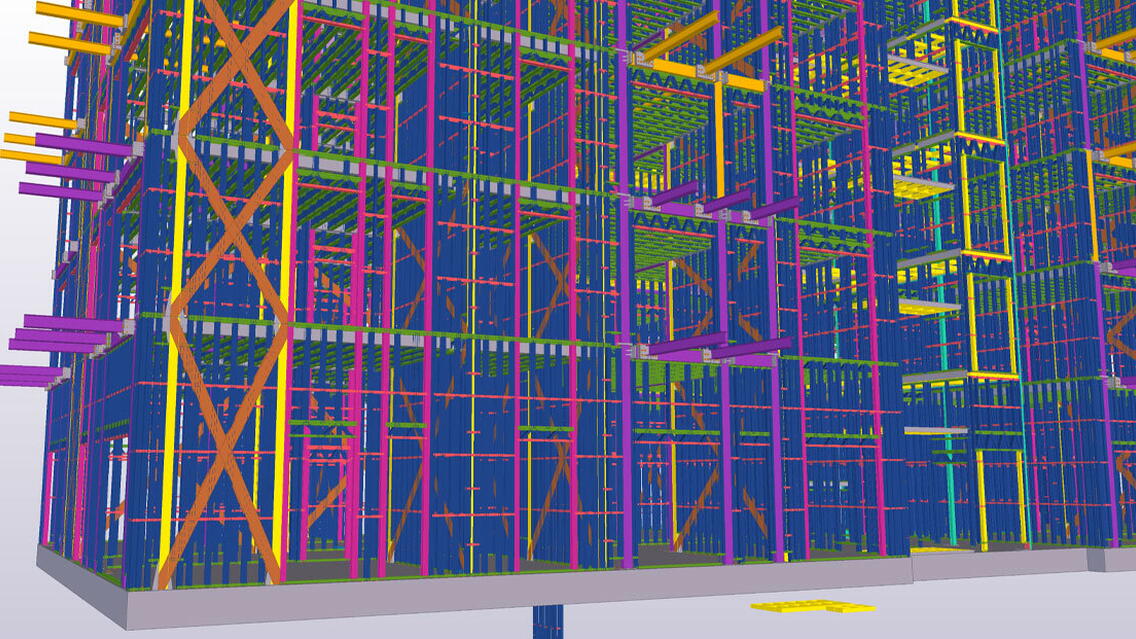

Load bearing panelised construction with lattice joist flooring. Co-ordinated services, stairs, and balconies off podium deck.

What were the challenges and what made the project successful?

Design coordination direct with Henley Architectural team via online portal allowed for improved information flow allowing for early design freeze.

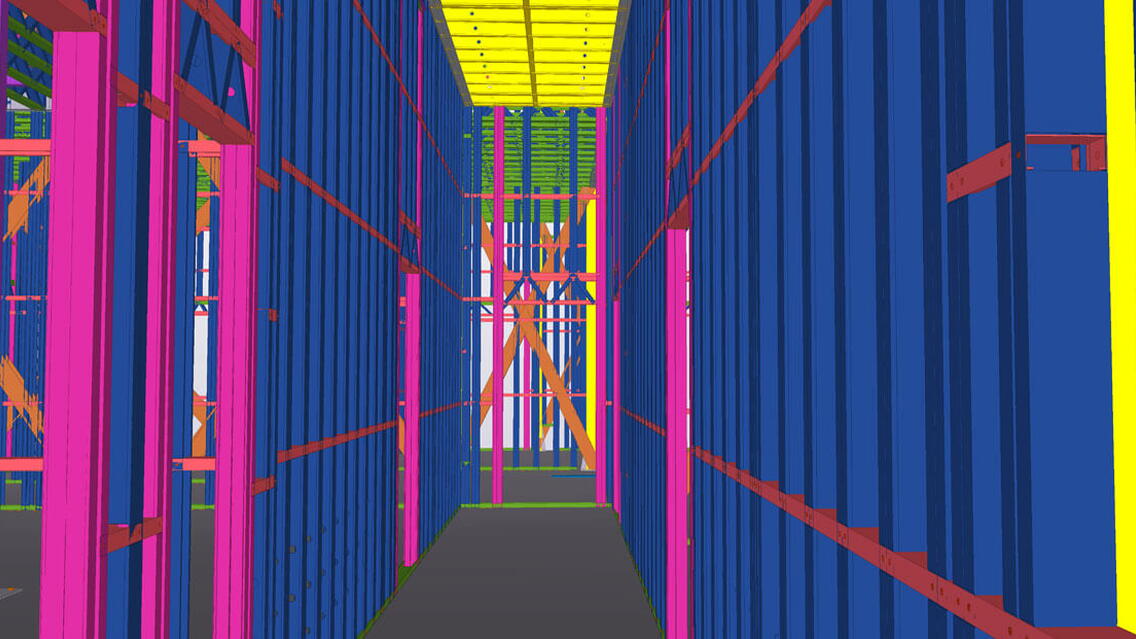

An extremely tight site on a busy thoroughfare to the national stadium meant fully coordinated deliveries was the only option without disruption to neighbours and businesses alike. To enable this to happen the phasing tool within Tekla was used to its full potential to help reduce deliveries. This ensured efficient batching of deliveries in coordination with site access and construction sequence, allowing for quick, efficient and flexible installation.

Also, by phasing elements it allowed us to issue material into manufacture to coordinate with deliveries which ensured all material was ‘racked and stacked’ ready to be issued to site.

Being able to utilise more resource within the same model through the implementation of a model share was also a beneficial factor for this project as we were able to continue processing one block into manufacture whilst finalising the design on the other block, which allowed us to stay within the programme timescales.

From the initial design inception, the client was given access to the Tekla model, which was used for the coordination of interfaces between the light gauge steel and other construction contractors such as M&E. The user friendly software, compatibility and various visualisation techniques allowed practical integration of other services as a timely cost-effective process. This also allowed the client and other disciplines to review and check the steel frame model against their models to ensure no clashes occurred.

What benefits did utilizing BIM and Tekla software bring to the project?

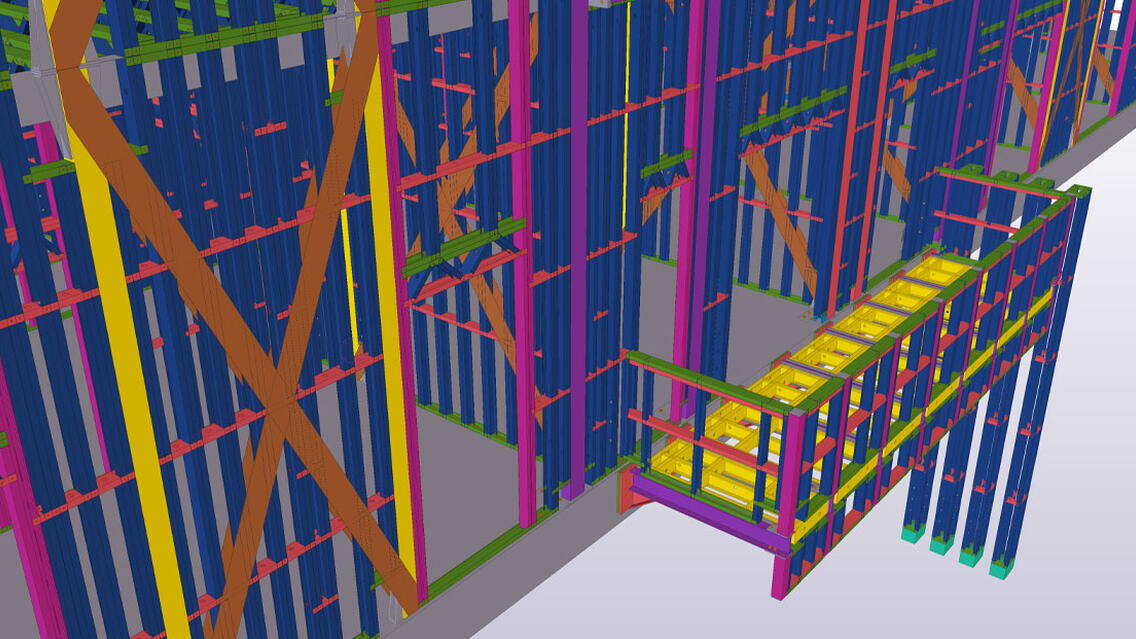

The success of completing design, manufacture and installation all within the required timescales, came from using a highly engineered product, using advanced CAD/CAM techniques. 3D modelling and BIM was used to ensure quality transpired through each stage of the project, from initial design through to efficient, right-first-time installation.

Using Tekla from project inception to create the structure was highly beneficial when it came to delivering accurate models and meeting the client’s brief:

- By importing reference models, the margin for error was reduced. This allowed the design process to flow more easily and ensure the client’s expectations were met with fewer revisions to the design.

- Having the ability to create IFC models enabled quick and easy sharing with the necessary people. This was beneficial as it kept all parties up to date with the current model, enabling effective clash detection and collaboration on any queries or design developments.

- Due to the size of this project, it was important to have confidence that the tools used could cope and manage with the large volume of data – the use of Tekla was key to gaining this confidence. Furthermore, having an element of repetition between floor levels, Tekla enabled us to store and re-use commonly used components saving time throughout the design process.

The use of Tekla as bespoke 3D modelling software and BIM, married with the use of a bespoke CAD/CAM interface to our roll forming machines, allowed the fully detailed design to be exported straight from design to manufacture. The pre-engineered solution was designed, manufactured and assembled on-site with confidence, creating a highly impressive building that exceeded the project expectations of both the client and main contractor.

The project in numbers

- Project value = £76 million

- Cold rolled steel = 720,000 linear metres

- Number of apartments = 248

- Number of storeys = 7 to 10 mixed-use scheme across 5 blocks

- Steel tonne = 1500t (approx)