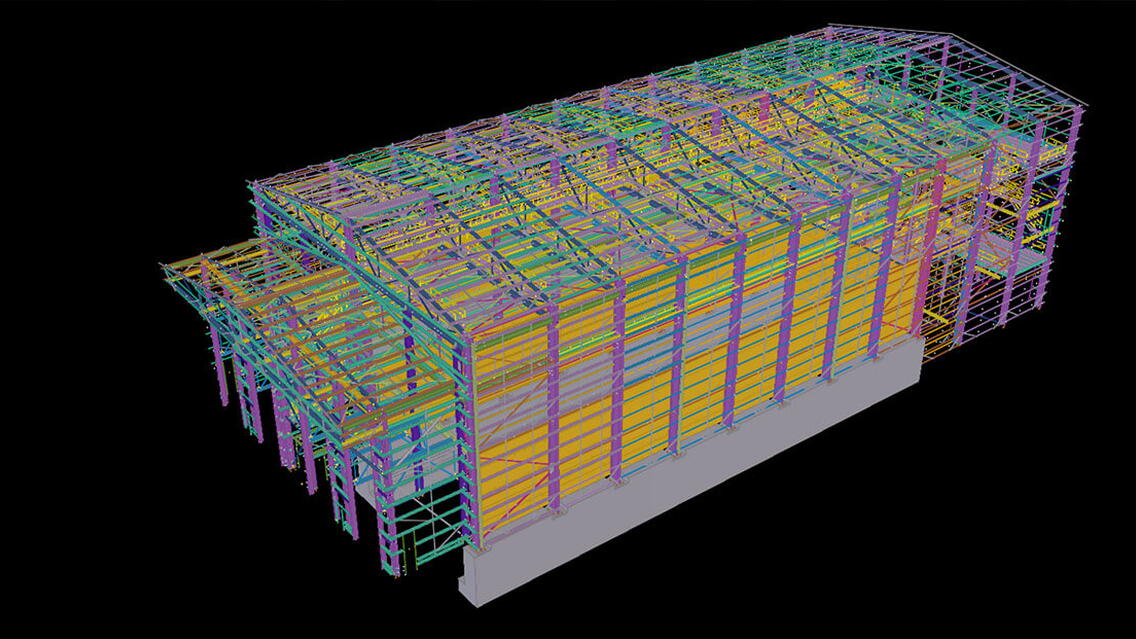

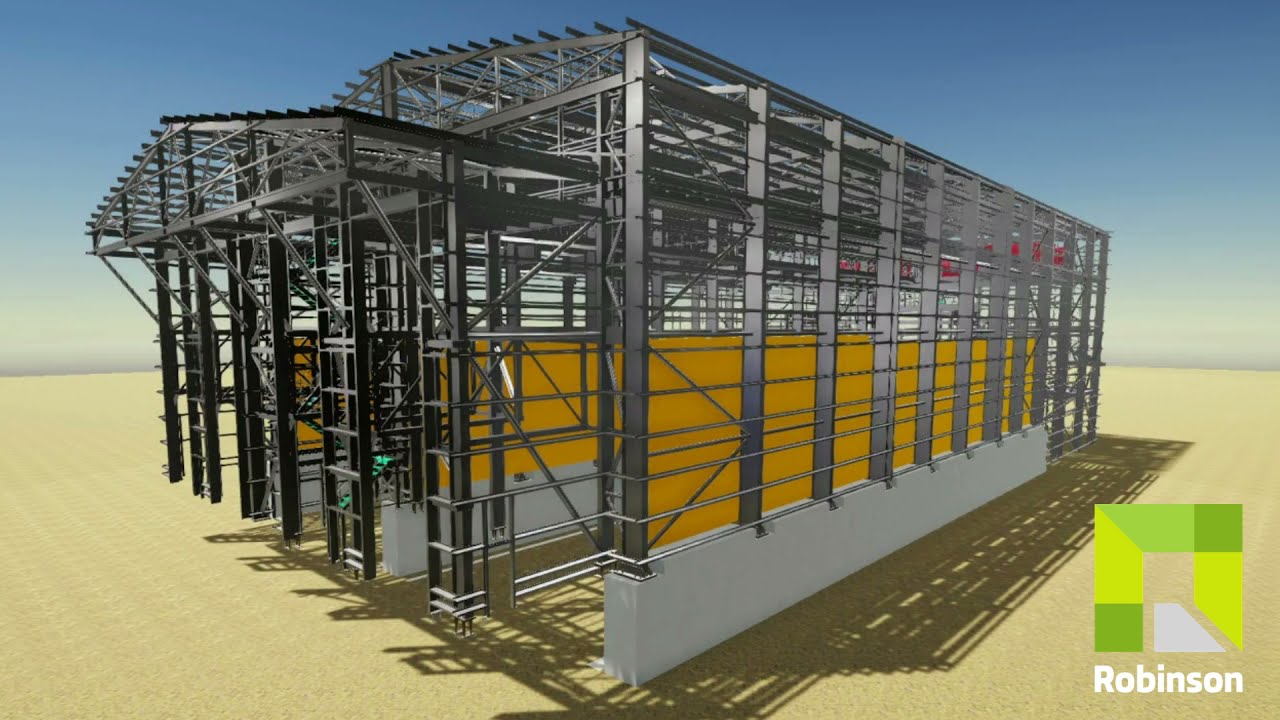

A large single span processing plant for Cemex at Rugby. The new building enables Cemex to expand their facilities for the production of concrete materials and also supplies them with a new storage building.

- The building consists of a single span braced steel building with roof trusses, multiple floor levels, cranes & basements.

- The building is approximately 32m in span and 21m high to eaves from the lowest level.

- Some of the columns are supported on concrete walls at a raised level whilst others are supported on concrete pad footings.

- There are multiple mezzanine floors to one of end of the building and a smaller canopy area to the opposite end. The canopy is full width of the building and approximately 14m to eaves.

- The building is stabilised utilising vertical and roof bracing. There is also bracing to the lower chord of the roof trusses.

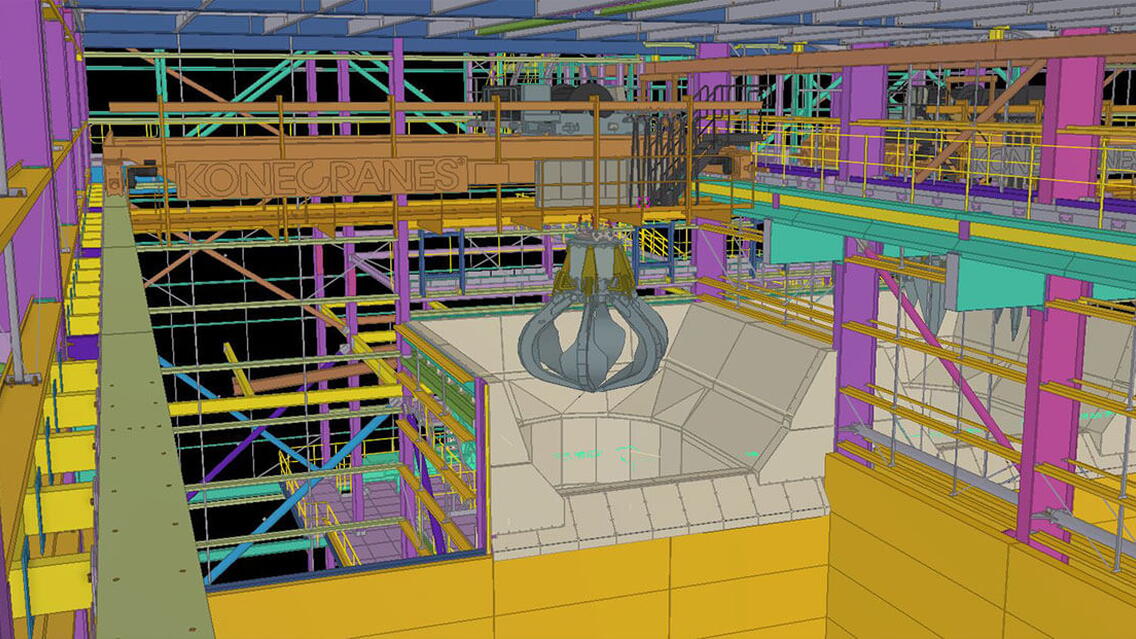

- The main part of the building is divided in two along its length by a dividing concrete wall with steel sheeted wall above. Each side of the building has an overhead crane running along the length.

What were the challenges and what made the project successful?

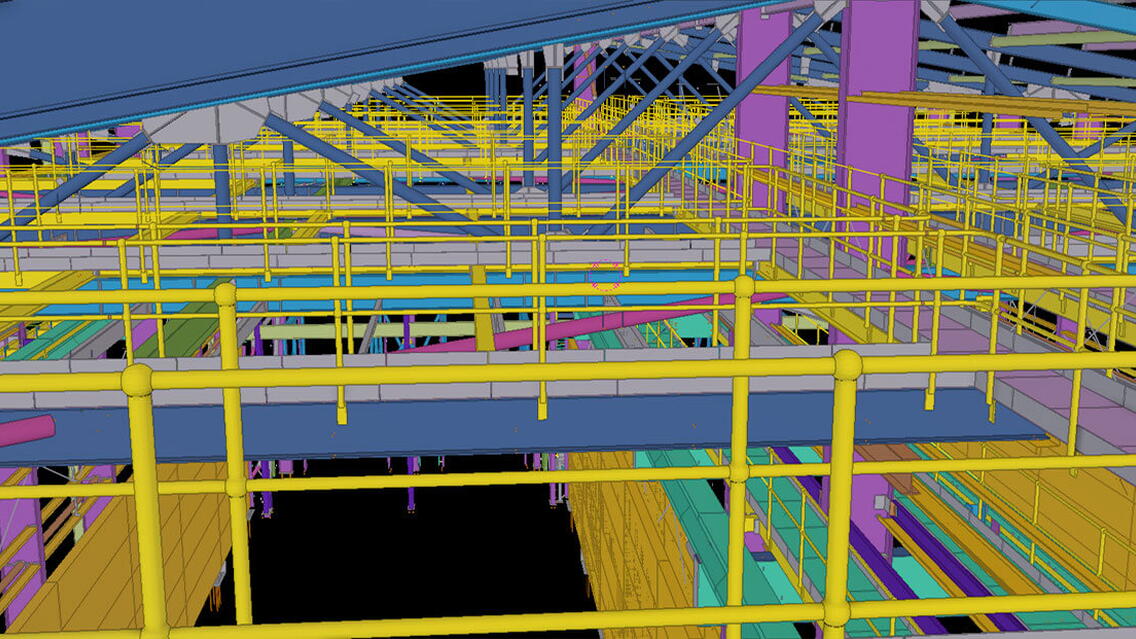

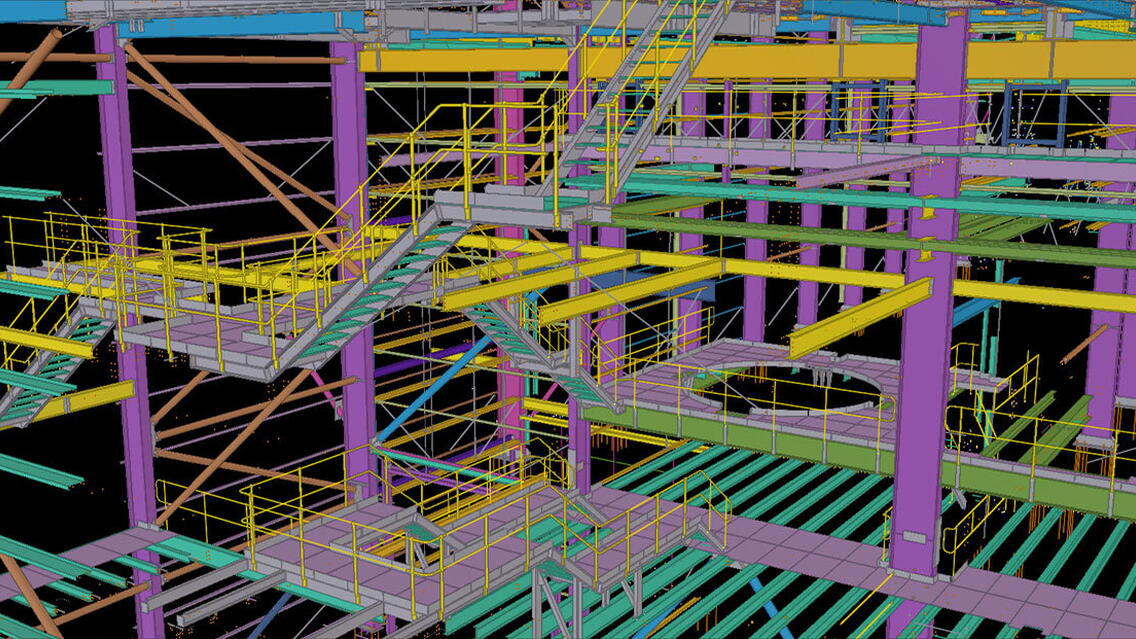

This prestigious project was a highly complex structure, multi-level design to accommodate various plant and machinery as well as an extensive truss structure to create an open space within the storage area of the building.

All aspects of the project from the main steel through to stairs, handrails, mesh and chequer plate flooring were completed in sequence utilising both in-house and external drawing offices through model sharing.

As part of Robinson Structures work there was a requirement to lift the hoppers, and conveyor machinery into place during the course of the steel frame erection, this entailed a tightly sequenced steel erection programme for this scheme to ensure that the main structure and secondary steelwork was at the correct stage for this to happen working alongside Cemex sub-contractors. The use of client BIM models for the plant uploaded to the steel frame model was invaluable in completing this activity.

What benefits did utilizing BIM and Tekla software bring to the project?

The detailing programme was as orderly sequenced as the erection phase to ensure that the main structure, secondary steel and the pre-cast concrete panels were issued in the correct sequence to ensure a smooth erection programme with a total of over 70 nr deliveries required to co-ordinate. We collaborated closely with Cemex sub-contractors utilising BIM methods by integrating the 3d models of the various hoppers and machinery into our steelwork model to run clash checks and help coordinate the works.

Utilising the Tekla Structures model sharing platform enabled Robinsons to work on the different aspects of this project whilst achieving the detailing programme.

Our contract department used Tekla Trimble Connect software to establish an erection sequence and this then allowed our site manager to keep track of the project progression during the erection programme phase and check installation details of complex connections.

The project in numbers

- Cost £3m (approx)

- 32m span x 78m long x 21m high

- 700t (approx)

- 192 Pre-Cast Concrete Panels

- 1250m of Handrailing