Situated in Manchester city centre where BBC North West was located, the site is now being transformed into a new neighbourhood known as Circle Square. The £750M mixed-use development will offer office space, retail outlets, serviced apartments and private residential accommodation as well as communal spaces open to the public.

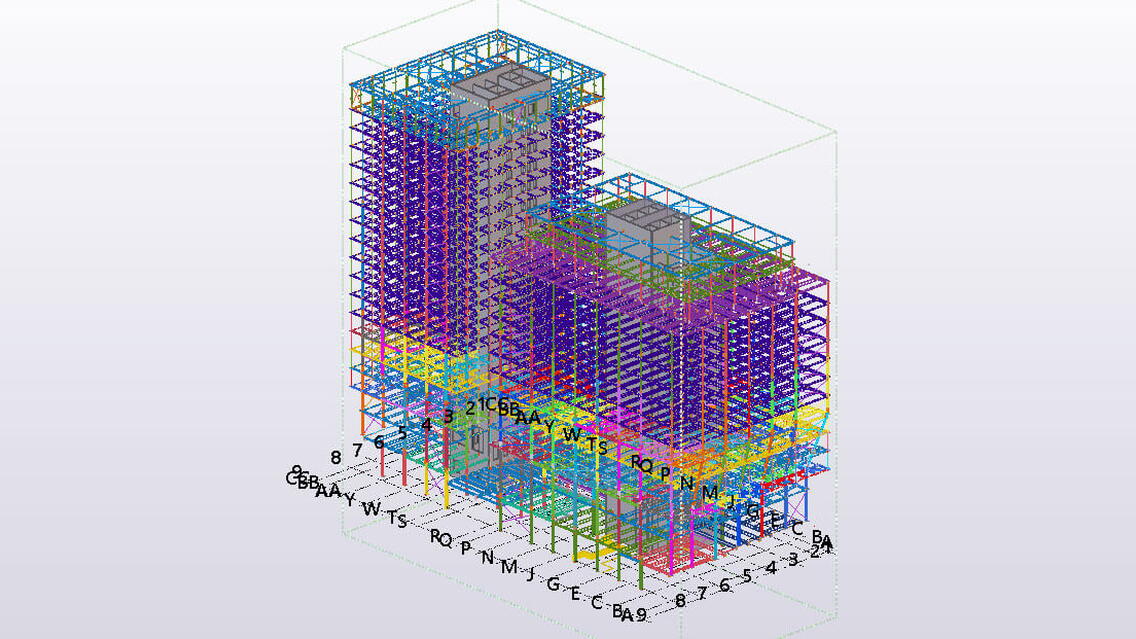

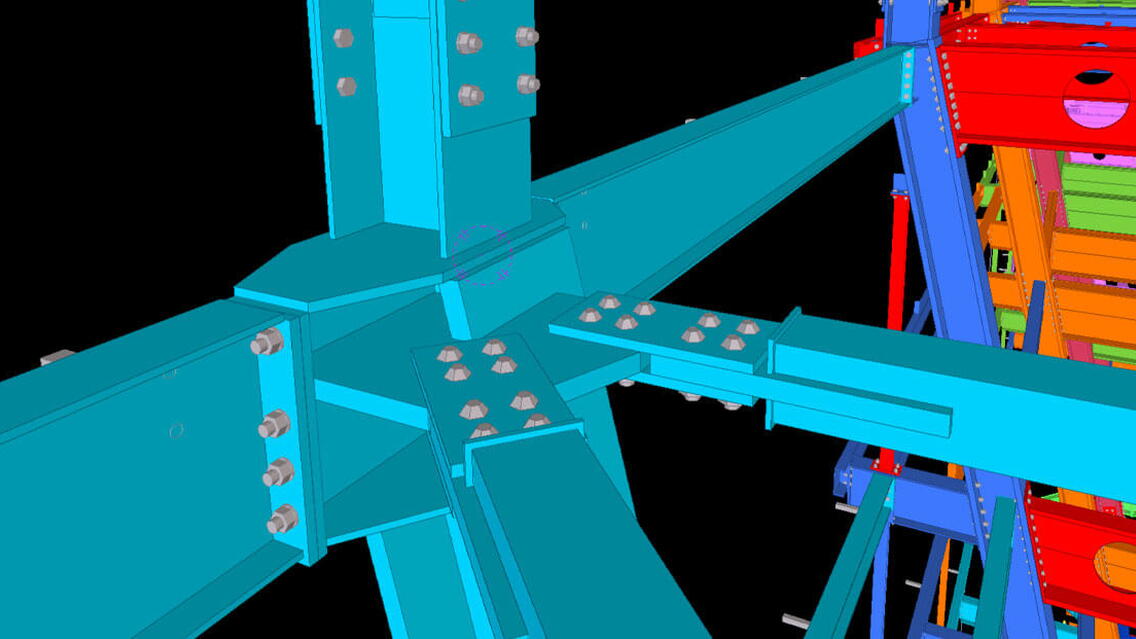

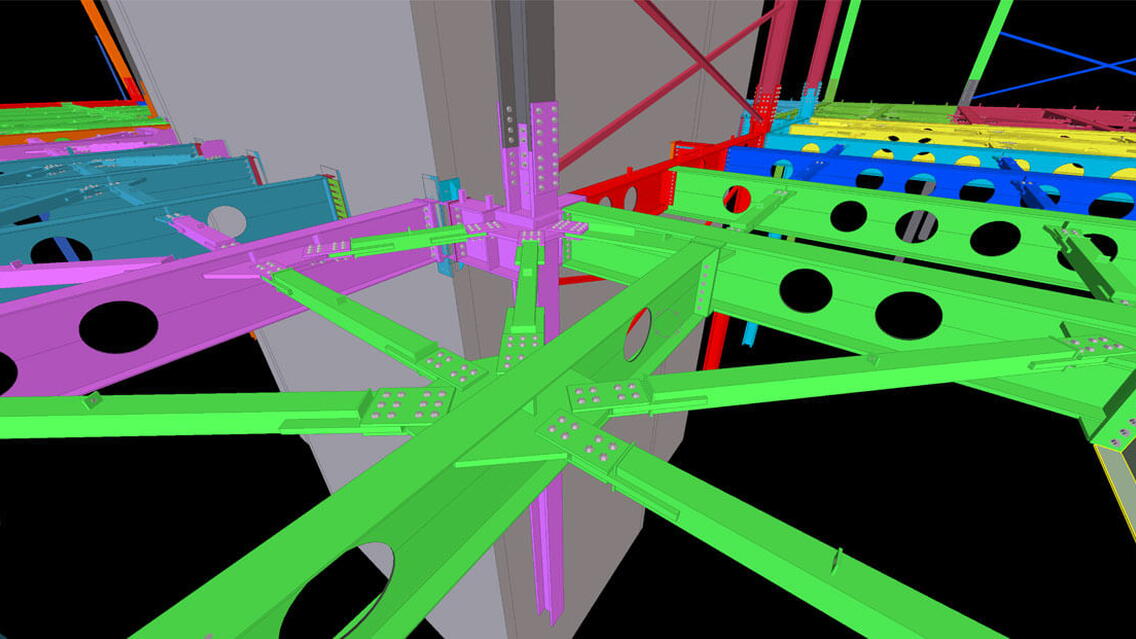

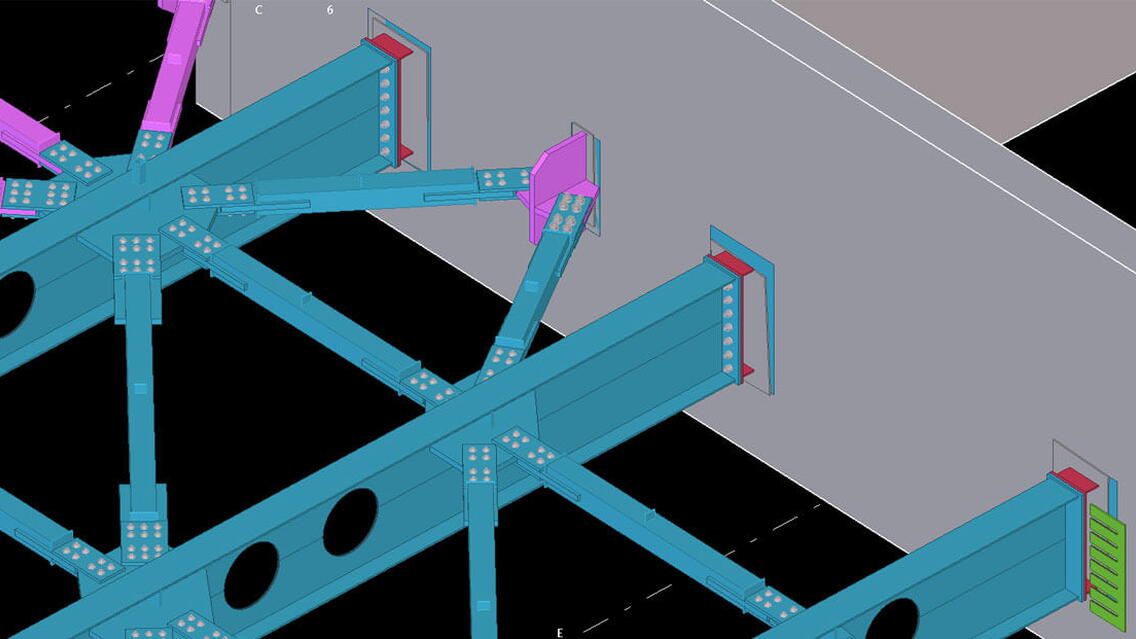

Due for completion by early 2021, the first phase includes two residential blocks and two adjacent commercial buildings which will be 17 storeys and 13 storeys. Circle Square 2 & 4 commercial buildings are steel-framed structures, compositely designed with steel beams supporting metal deck flooring and a concrete topping. The beams are all bespoke plate girders containing fully co-ordinated web holes to accommodate the services within their depth.

One of the key features of the scheme occurs in Building 4, where the main support columns to 3 sides of the building rake out from Level 2 and up to Level 5. This creates extremely large overall compression forces at Level 2 and tension forces at Level 5. It was considered by the Structural Engineer that these forces were too large to be catered for by a traditional composite concrete deck floor diaphragm and hence significant and highly loaded plan steel floor bracing occurs at these 2 levels to transfer the forces into the concrete cores. Due to the requirements of M&E distribution, Billingtons had to ensure that the bracings and their significant connections were to fit within a limited space within the overall floor zone. More manageable tension forces at Levels 3 & 4 are dealt with via concrete floor diaphragms.

What were the challenges and what made the project successful?

The design development programme was very condensed at the start and still ongoing when the steel contract was awarded. In particular the unusual structural form and highly loaded nature of the braced floor plates at levels 2 and 5 meant significant co-ordination between Curtins and Billington Structures was required to arrive at practical and sufficient solutions for bracing nodes and cast in plate fixings to the core, that satisfied the various design constraints of the building, and to allow on programme supply of cast-in items for the core construction.

What benefits did utilizing BIM and Tekla software bring to the project?

The entire fully detailed steel structure was modelled in 3D using Tekla Structures, allowing full co-ordination with the Architectural and Engineering models, together with easy clash checking both visual and otherwise.

The project in numbers

Billington Structures have provided over 3,700 tonnes of steel in total across 2 individual structures. The structures are expected to achieve a BREEAM ‘Excellent’ rating and will offer 21,300m2 of floor space in No.2 and 14,000m2 in No.4.

- Size = Two buildings, 13 and 17 storeys high with connecting podium structure at low level

- Steel cost = £8.5m (approx)

- Tonnage = 3,760t in total

- Piece count = 49,000 (approx)