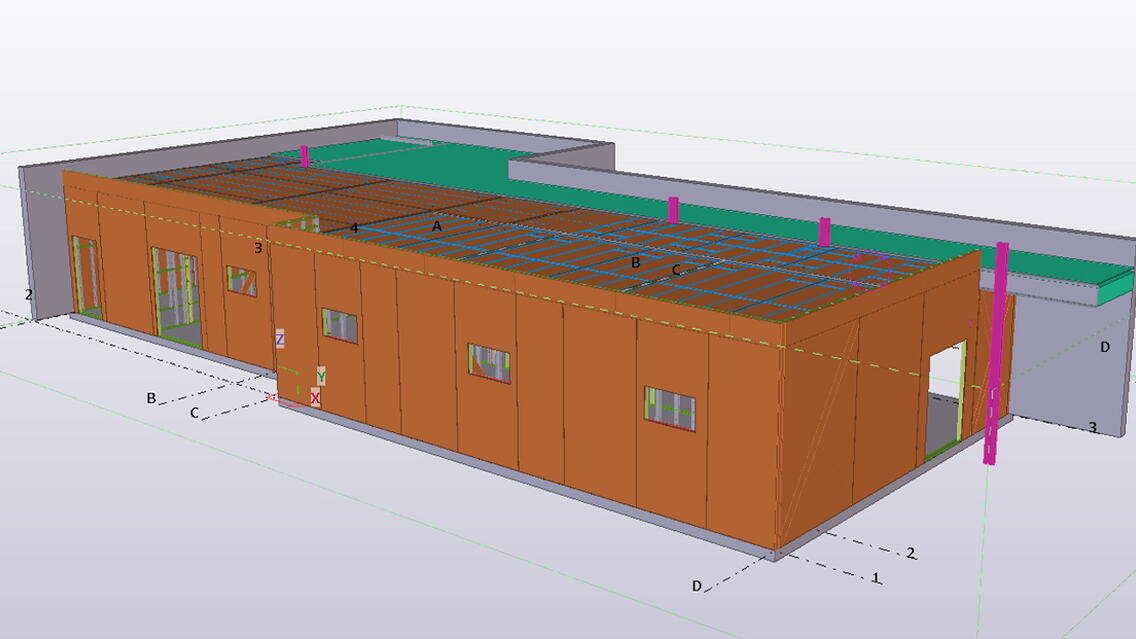

The new facility, which has been procured under the new NHS Shared Business Services framework, will be installed on the hospital’s existing car park and comprises of 21 Clinic Rooms, a 4 bed Infusion Bay, an X-ray Department and Ancillary Accommodation.

It was extremely important that the new facility was a standalone building completely separate from the main hospital. This was due to the nature of works that were to take place within the Outpatients Department. As it treats day patients only the Trust wanted to minimise, if not completely remove, the possibility of secondary infections. If the department was situated within the main hospital, this would increase the chance of secondary infections to day patients.

Time was of upmost importance to the Trust as the current Outpatients Department was being refurbished into an extension to the Accident and Emergency Unit. Therefore, the new modular facility was fast-tracked and completed in just 9 weeks from receipt of order; Work commenced with design works at the beginning of August 2018 and these were completed by the end of the same month.

What were the challenges and what made the project successful.

As this was an extension to an existing building, the main challenge was keeping disruption to a minimum whilst the building remained open for use. Ambulance access had to be maintained at all times. Providing pre-panelised, pre-boarded frames reduced the work onsite by doing offsite at our factory.

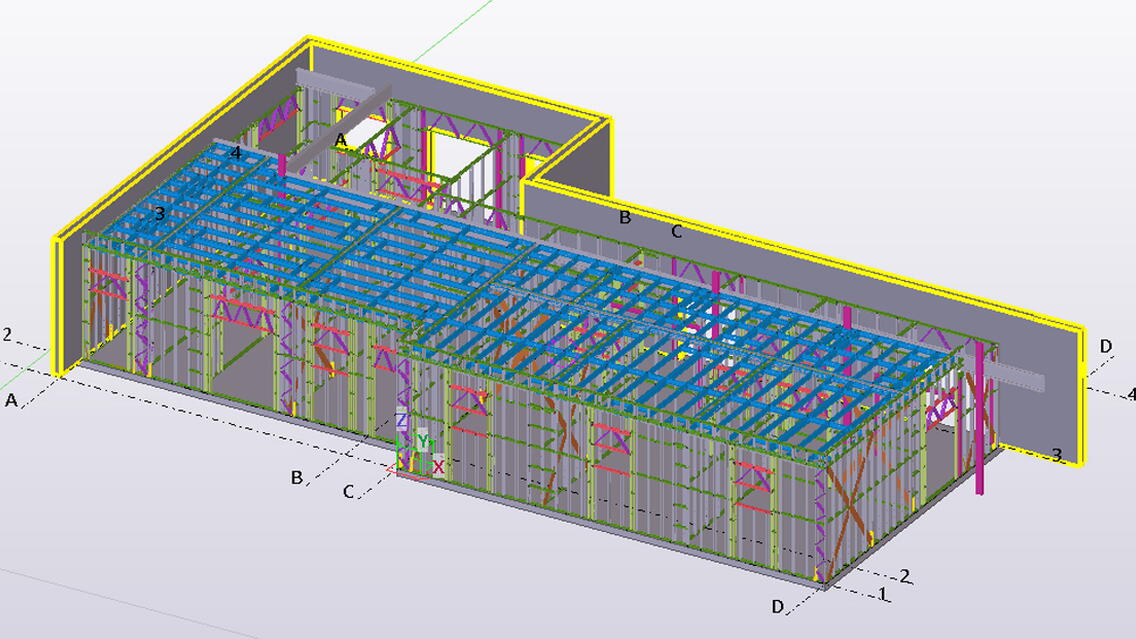

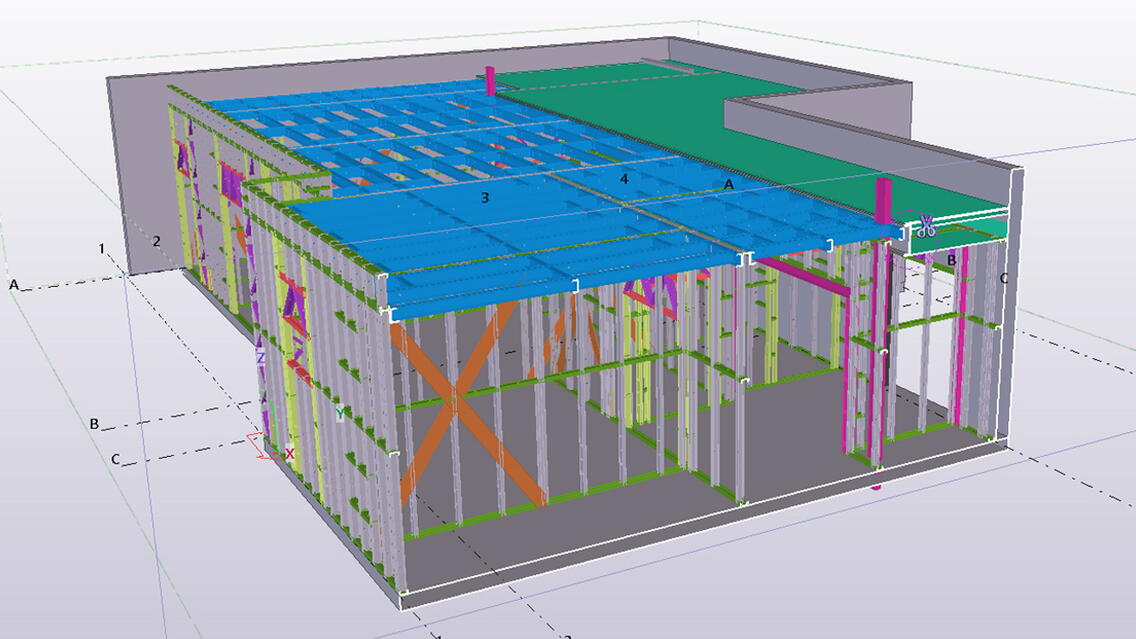

Due to the time constraints on both design and manufacture, it was highly important we were able to utilise Tekla combined with the knowledge of our designers to ensure a positive outcome was achieved. To enable this to happen the phasing tool within Tekla was used to its full potential to help reduce deliveries. This ensured efficient batching of deliveries in coordination with site access and construction sequence, allowing for quick, efficient and flexible installation, co-ordinated closely with the hospital.

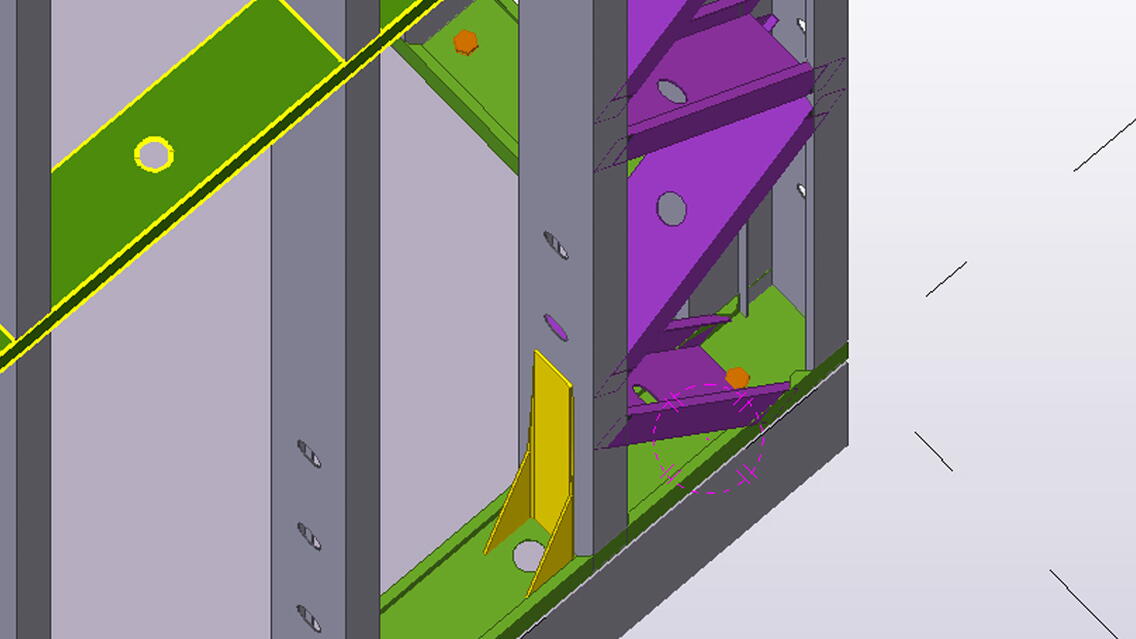

Due to the location of the site restrictions, steel frames were to be kept below a maximum weight, enabling easier manoeuvrability. Being able to easily select a frame using the custom inquiry to provide weights etc became a good advantage from using Tekla. This was also helpful as panels were modelled with the external board on, therefore this weight also had to be taken into consideration, not only did this give the client a visual of the structure to be delivered, but the information was also easily exported and passed to manufacture to minimise factory waste and increase efficiency of material ordering, providing a pre-determined bill of quants of raw material for purchasing and programme optimisation. This also contributed and resulted in an effectively weathertight structure as soon as possible.

Changes to this project were made quite late in the design stage, however due to Tekla we were able to add these into the original model very easily and re-issue showing the amendments. Also, we were able to phase the amendments which made it easy and clear when issuing into manufacture.

What benefits utilizing BIM and Tekla Software brought to the project.

Using Tekla from project inception to create the structure was highly beneficial when it came to delivering accurate models and meeting the client’s brief:

- Having the ability to create IFC models enabled quick and easy sharing with the necessary people. This was beneficial as it kept all parties up to date with the current model, enabling effective clash detection with the existing and collaboration on any queries or design developments.

The use of Tekla as bespoke 3D modelling software and BIM, married with the use of a bespoke CAD/CAM interface to our roll forming machines, allowed the fully detailed design to be exported straight from design to manufacture. The pre-engineered solution was designed, manufactured and assembled on-site with confidence, creating a highly impressive building that exceeded the project expectations of both the client and main contractor.

The project in numbers

Steel Tonnes - 4.899 approx.