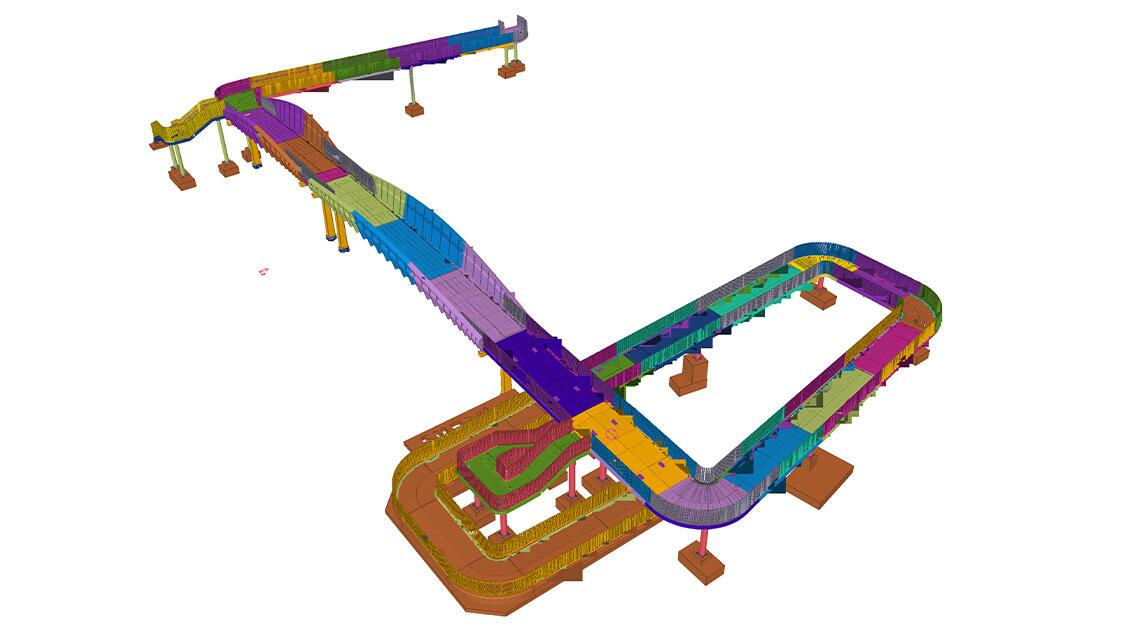

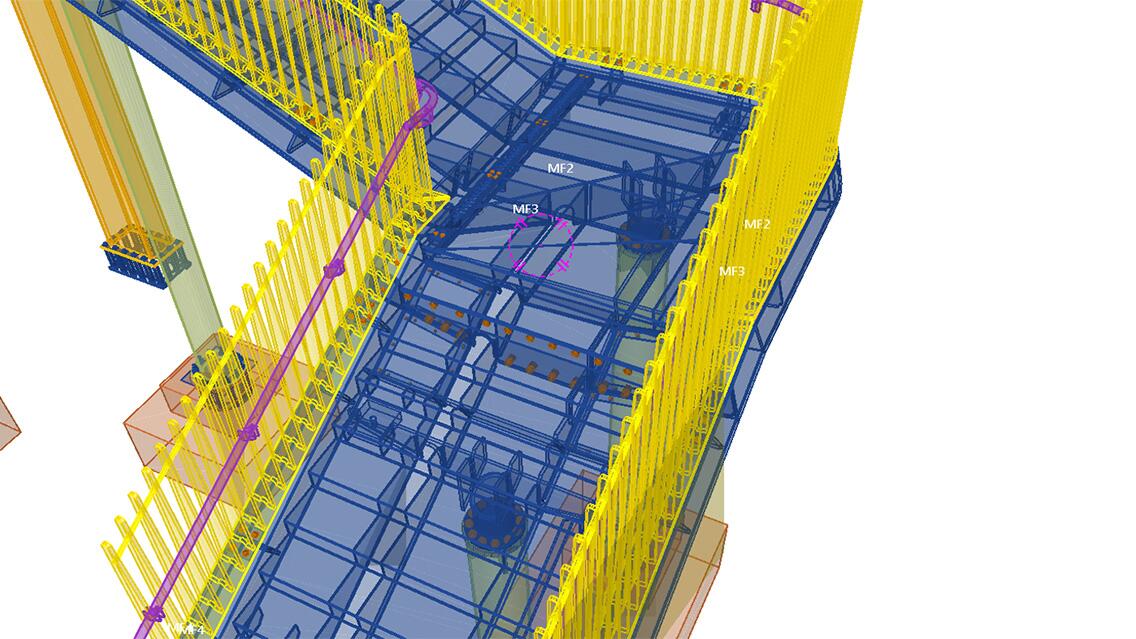

New footbridge, ramps, and stairs for Newport Railway Station. A structure made out of plated material, with complex geometry, difficult fabrication techniques, and restrictions on erection.

Independent Design House were engaged by Prosteel Engineering, who were working for the principle contractor, Alun Griffiths, for, and on behalf of, Newport City Council to produce a fabrication model for a new access ramp and footbridge at Newport Station.

Accurate complex shaped plates

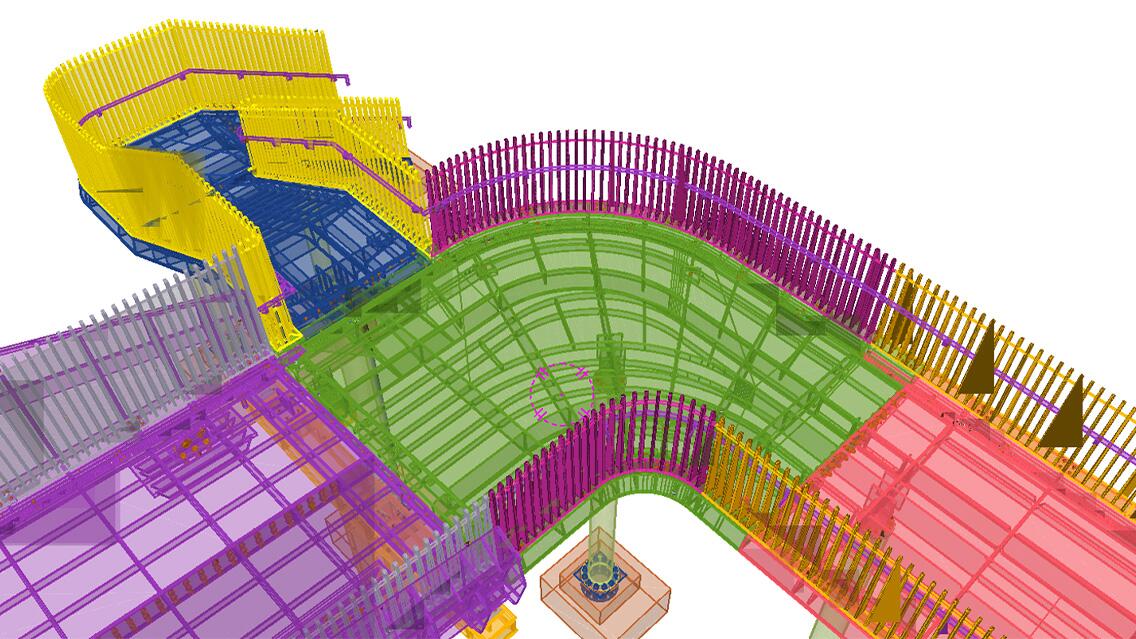

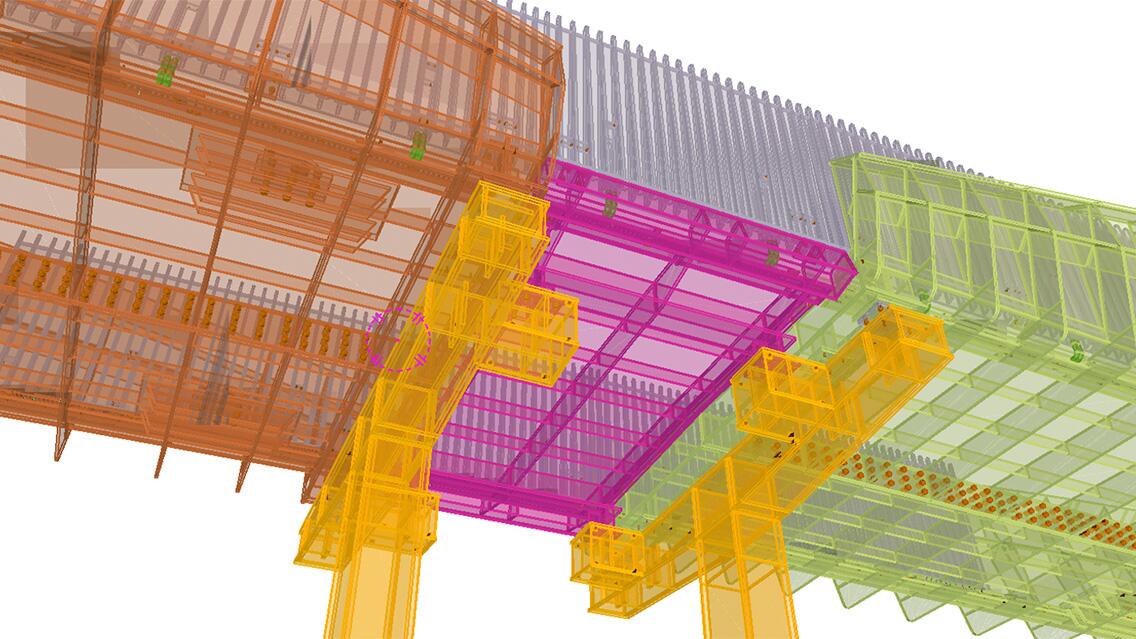

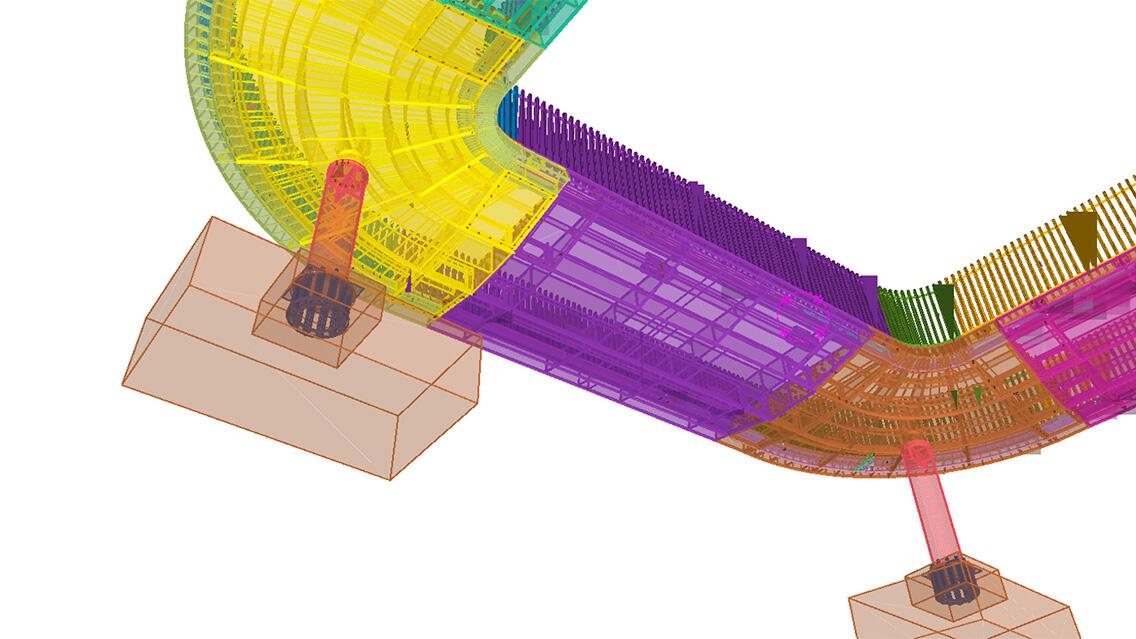

Comprised of over 15000 individual plated parts with an extremely complex geometrical setting out, which included curved plates that were arcing / sloping in two directions, meant a challenge for setting out via traditional 2D drawing methods. By using design reference models supplied by the consulting engineers, CASS Hayward, we were able to accurately detail the geometrical data for the model and easily share models for review .

A big advantage was the ability to use the "lofted plate" option in the Tekla software, for creating accurate complex shaped plates which we were then able to unfold using the “triangles generation” macro coupled with the “unfold surface macro. From this, the IDH could then pass on the NC data to ProSteel, who were then able to work with flat sheets of steel, forming the final shape in the workshop. This would not have been feasible using more conventional options for modelling the bent and curved plates.

The Tekla Structures program dealt extremely easily with the many problems encountered in this challenging project!

Important points or benefits:

- Individual steel parts: Over 15000

- Bolts: 6400 bolts

- Tonnage: 460t

- Custom components were created for the parapet steel