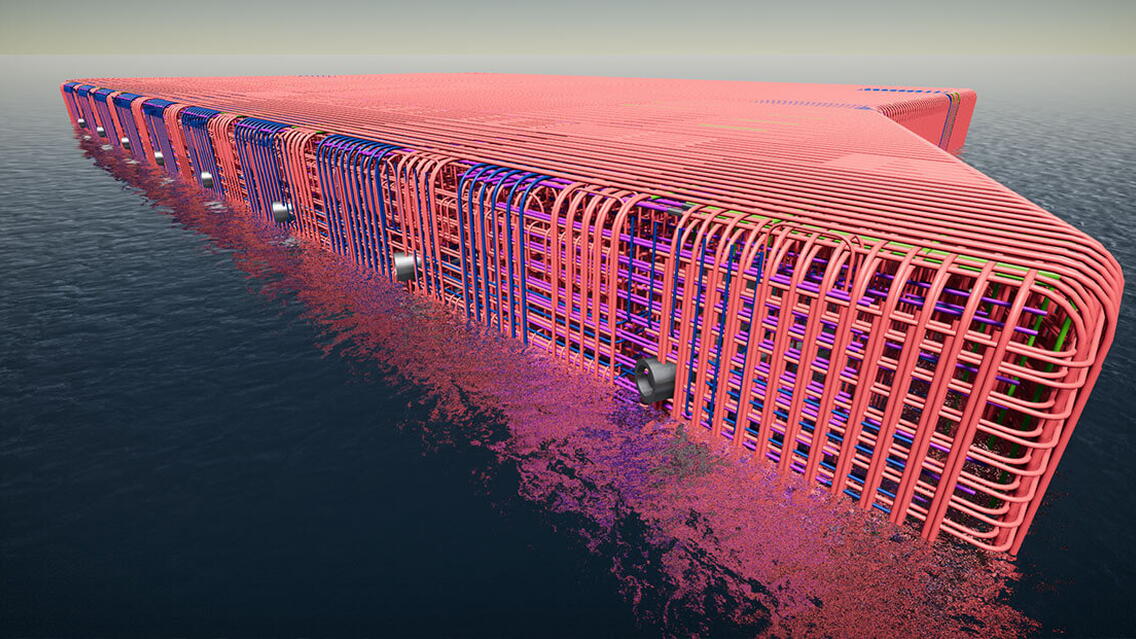

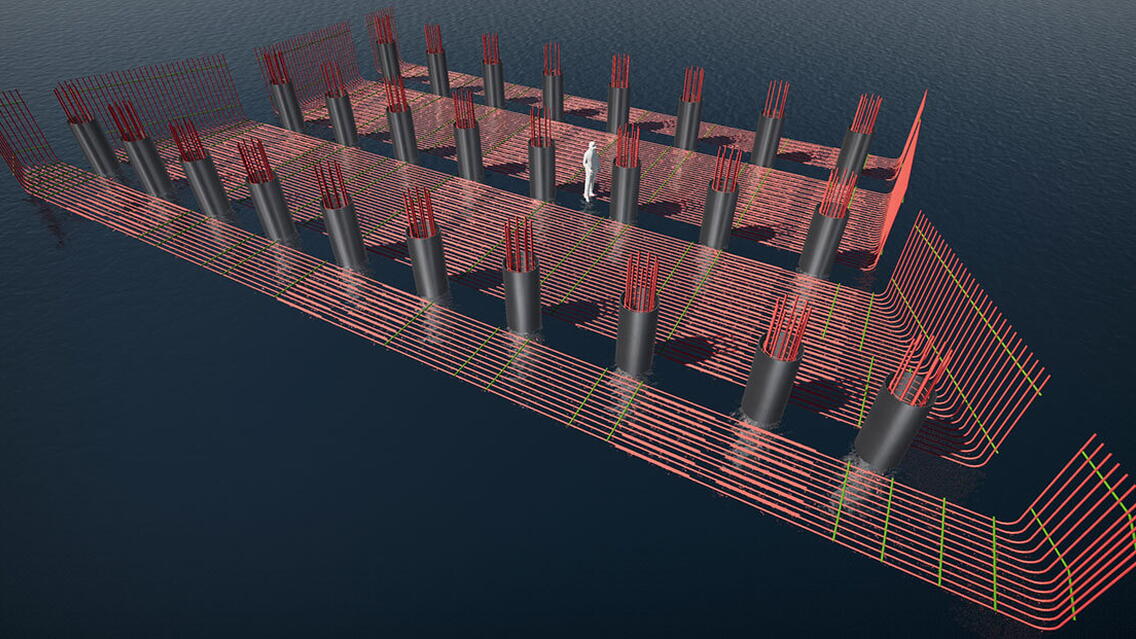

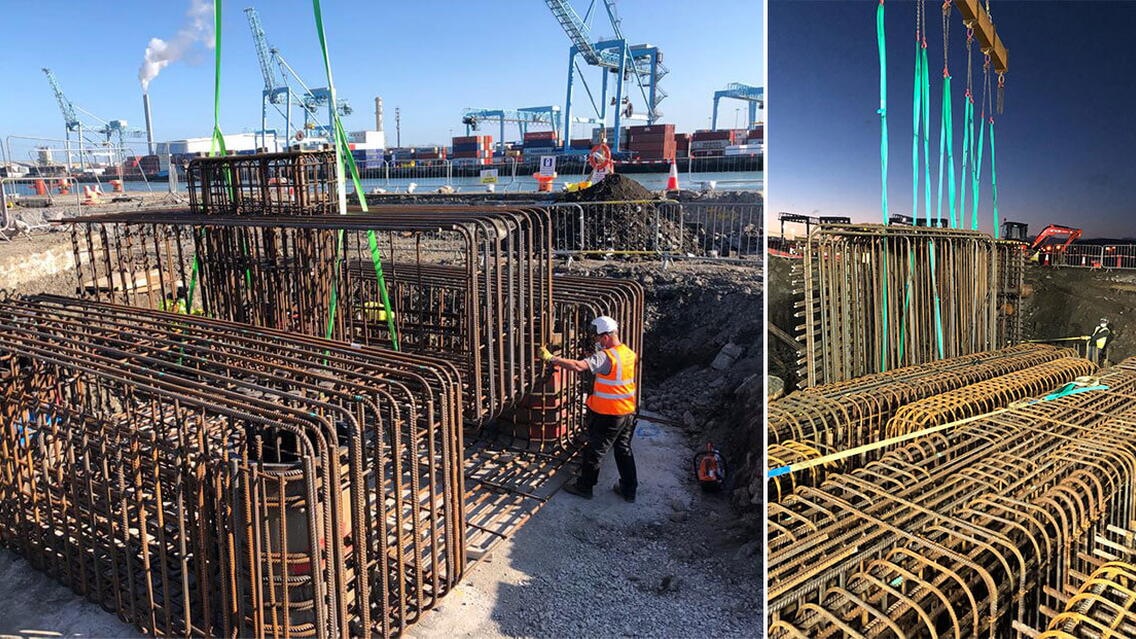

This raft slab is to act as a counterweight for the new docking area at Dublin Port. The 29m long, 16m wide and 3m deep slab had a total of 285 tonnes of reinforcing steel all detailed using Midland Steel’s FasterFix Modular Rebar process. Detailed, delivered and installed modularly, this large raft slab was installed, backfilled and poured in 8 working days saving between 4-6 weeks on the construction programme in comparison to traditional steel fixing.

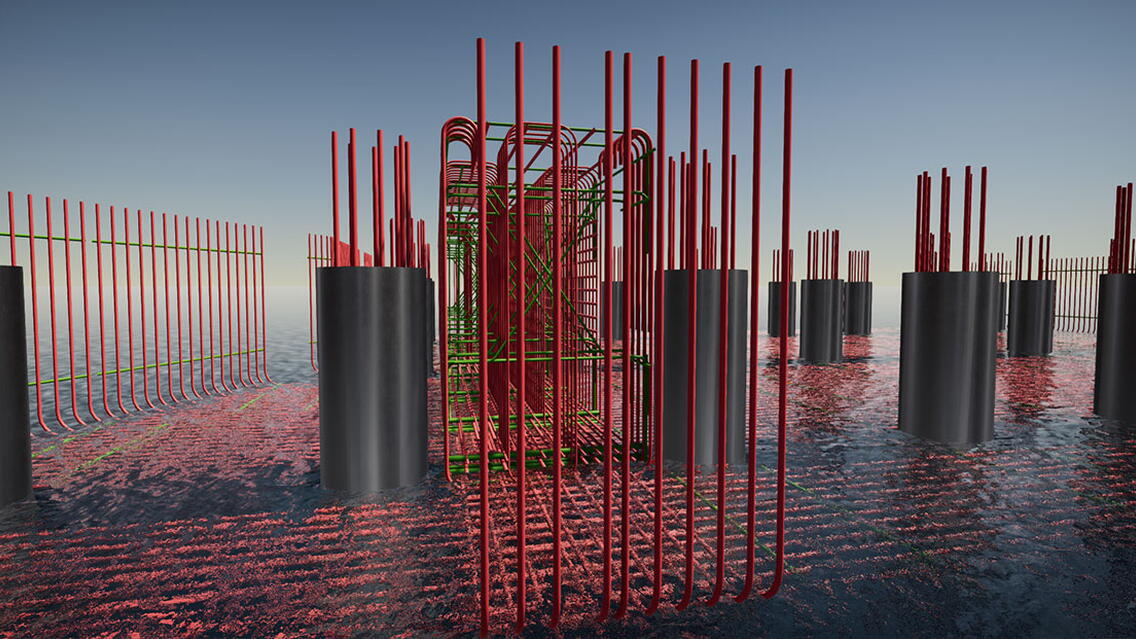

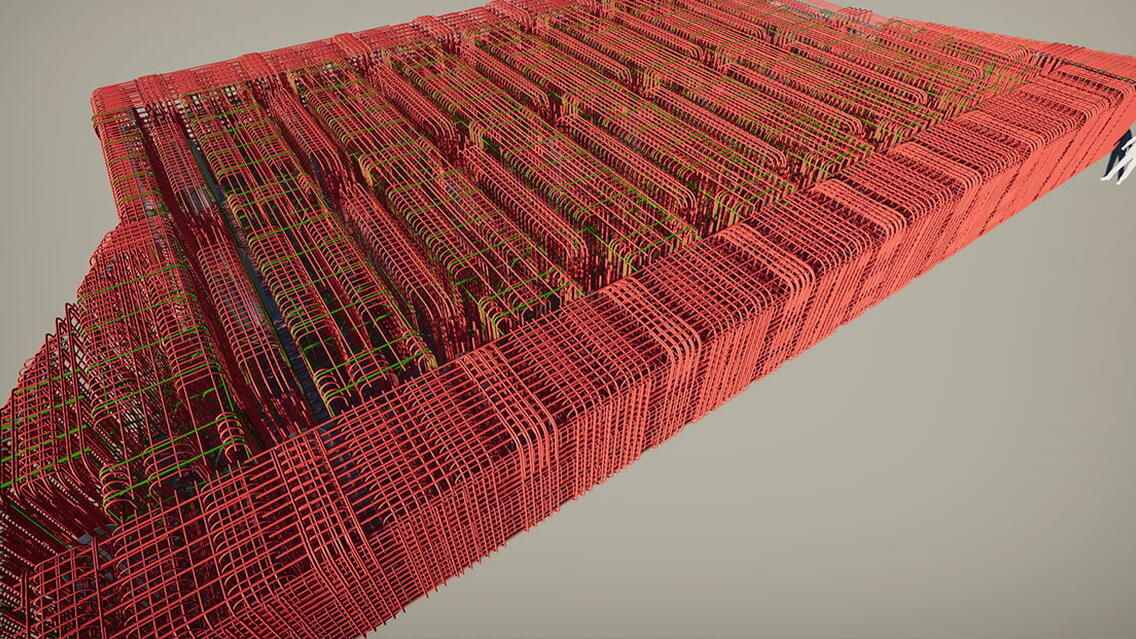

Due to the design of the reinforcing steel and the strict timeframes of working with the tide level, this project has been identified as an impossible task to complete using traditional steel fixing methods within a workable timeframe. The bottom layer of the raft slab consisted of 6 layers of 32mm rebar with 4 in the top layer with 32mm rebar also. The entire slab was detailed into cages ranging from 1 tonne to 26 tonnes with temporary works all provided by Midland Steel. Through modularising the process with Midland Steel’s FasterFix approach, 75% of the onsite labour was eliminated resulting in a controlled and safe installation process onsite.

What made this project special was the use of Tekla’s feature to mimic the water level height in the 3D model. This feature enabled for the exact times the modular reinforcing steel cages could be placed by using the tide height data and then replicating this data within the model. Without this feature, all planned concrete pours would have been estimated and presumptions would have been made. Tekla software allowed for the entire reinforcing steel installation phase to be visualised and matched with times to plan the working times for this project.

What were the challenges and what made the project successful?

The initial challenge presented was the multiple layered design required on both the bottom and top layer of reinforcement. In a traditional setting, this challenge would have been a dangerous and almost impossible task to assemble the required rebar detail in situ.

Solution: BIM. Through the use of Midland Steel’s FasterFix and BIM process, Tekla software was used to detail this raft slab. With visualisation and animations, the assemble process was clearly presented to all project stakeholders before any steel was fabricated. This allowed a full safety review and feasibility test to take place both digitally and at Midland Steel’s production facility. Due to the congestion of bars on both layers of the slab, the clash detection tool was vital for productivity. Not only was productivity increased, but health and safety concerns and potential accidents have also been avoided on this project by using Tekla software due to identifying risks before any bars have been fabricated. Assessments of how the modular cages could be assembled had been in constant review during the detailing phases with multiple brainstorming sessions using the BIM model to visualise and plan the assembly process.

The next challenge was working with the tide. The site conditions and strict timelines would have proved an almost impossible task by using traditional methods.

Solution: Modular reinforcement. Midland Steel has been using Tekla software for over 10 years to detail modular solutions. By following the FasterFix process, a modular solution was detailed to incorporate the number of layers of rebar required into cages and one-way meshes. With a pump running 24/7 to keep the foundation from flooding, the installations had to be optimised at low tides with concrete pours planned as soon as the last cages had been positioned. What made this schedule more complicated was that the Christmas shutdown period was approaching meaning if the foundation was left un pumped, wet clay would have settled at the base around the reinforcing steel cages resulting in an impossible task to remove it all with the rebar in position. The planning of this installation and pour was the most critical part with the Tekla visualisation allowing a full hour-by-hour schedule as to when the cages could have been dropped into position and working safely on.

Midland Steel Reinforcement Supplies are proud to have contributed to this project from the detailing right through to the installation. With early involvement, our BIM and prefabrication experience assisted this project in the installation of the anchor block raft slab at Dublin Port. Our proudest involvement in this particular project was reducing the constriction programme by an estimated 4-6 weeks by using Midland Steel’s FasterFix Modular Rebar process. Over the last 10 year, Midland Steel has built a strong technical team that uses Tekla software daily to detail our ideas and solutions for the Irish and UK construction sector.

What benefits utilizing BIM and Tekla brought to the project?

This project would not have resulted in the success witnessed without the use of Tekla as agreed by Midland Steel, the consulting engineer and the contractor. The visual aspect allowed an enormous amount of preplanning to take place. Our production team was able to assess how the cages could be assembled in our factories and how they could be loaded/delivered. Our detailing team was enabled to visualise how the modular units could splice together and how they could incorporate the tie rods (Which would have been another onsite manual intervention but was incorporated during the detailing phase to work with the modular solutions) and the onsite team was able to plan the installations due to the visual representations of the tide level.

Overall, Tekla enabled a vision for a modular solution for this project which turned a 5-week program into 8 working days. The precision we could work with was mm perfect with one particular site video illustrating this. With pile plugs underneath the reinforcing steel cages, the installation of these cages had to be mm perfect to fit around the pile plug’s starter bars. The video can be found in the supporting link in the Animations_Video Clips folder.

With the 6 layers of 32mm rebars on the bottom and 4 layers on the top layer, the clash detection tool was a must-have for this project and without it would have caused cartographic delays onsite for these bars were to be fixed manually. The interaction with the model allowed for immediate awareness of what would and would not work and highlighted many issues before any cages were assembled in our factories. Using the Trimble Connect app, it made it very easy to check the cages in our factory as they were being made with the use of an iPad. All cages were approved by the Site Engineers in Midland Steel’s factories before being delivered as the time schedule was so strict. The Trimble Connect app played a vital role to allow this approval to take place.

The project in numbers

- Anchor Block - 285 tonnes.

- Dimensions - 16m x 29m x 3m, 1,392 cubic m.

- 26 Pile plugs, 31 prefabricated beams & 56 special meshes.

- Reduced the construction programme from 5 weeks to 8 days.

- 75% labour reduced onsite by using modular Midland Steel’s FasterFix approach.

- By including the tie rods/anchor rods in the detailing and in the preassembled cages saved the contractor 1 week of onsite labour.