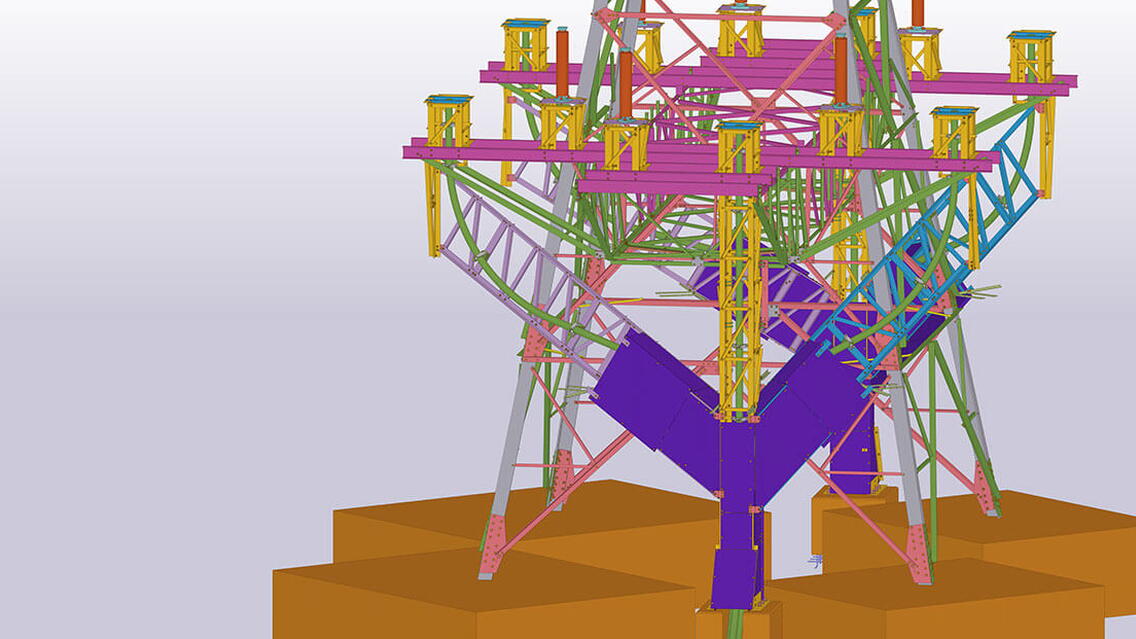

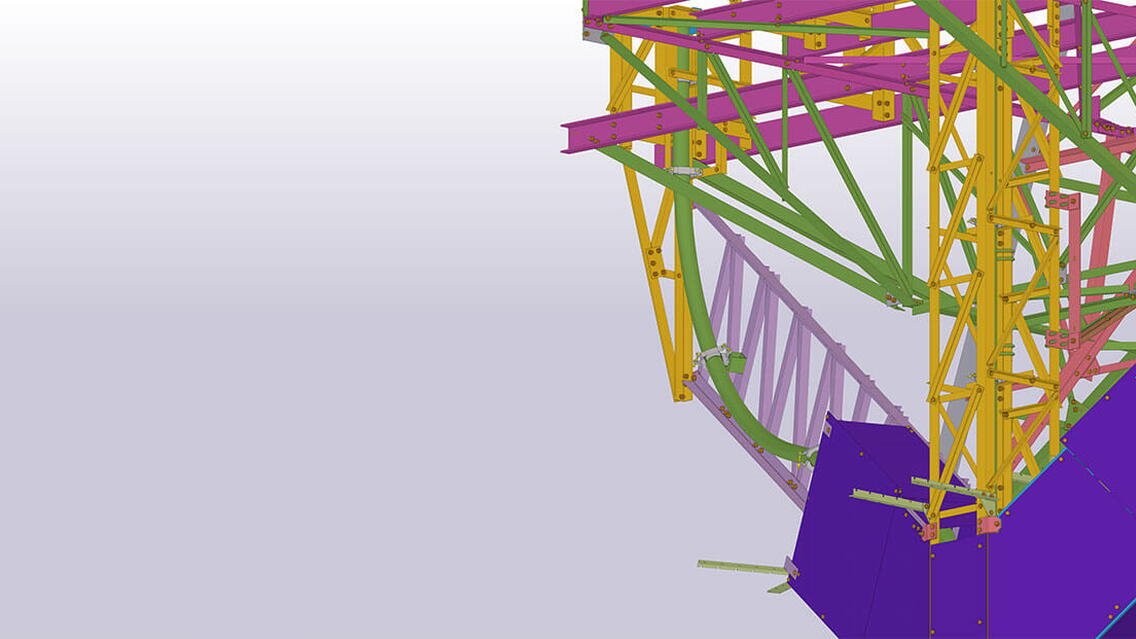

We had to come up with a trefoil ladder design where the 105dia cable could bend and not clash with any of the existing steelwork which proved very tricky with a min bend radius of 2.6m.

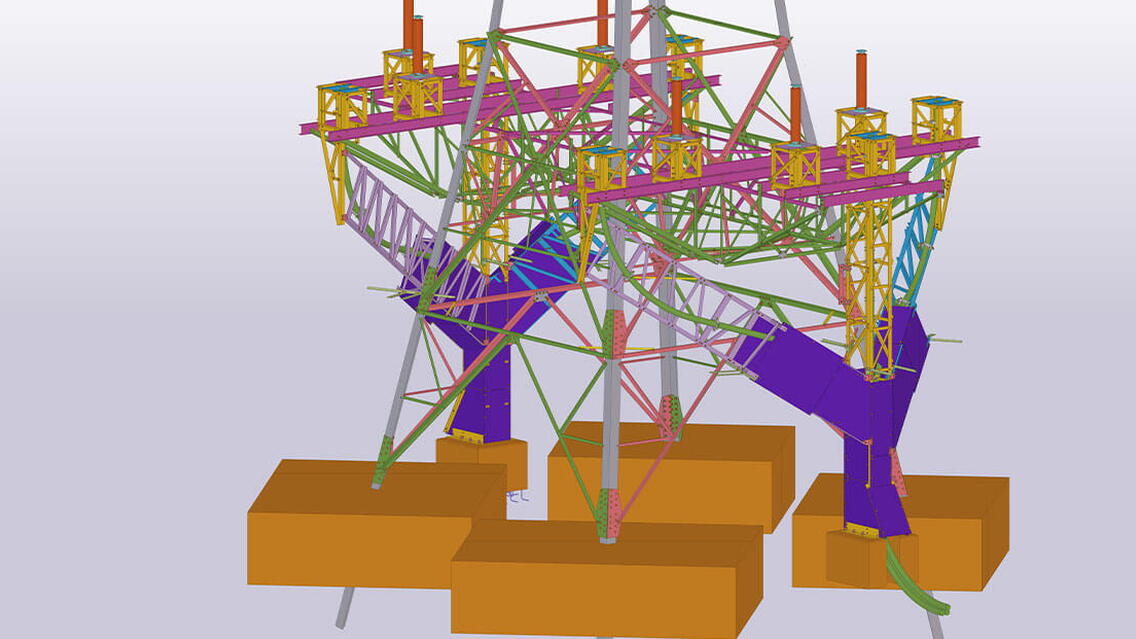

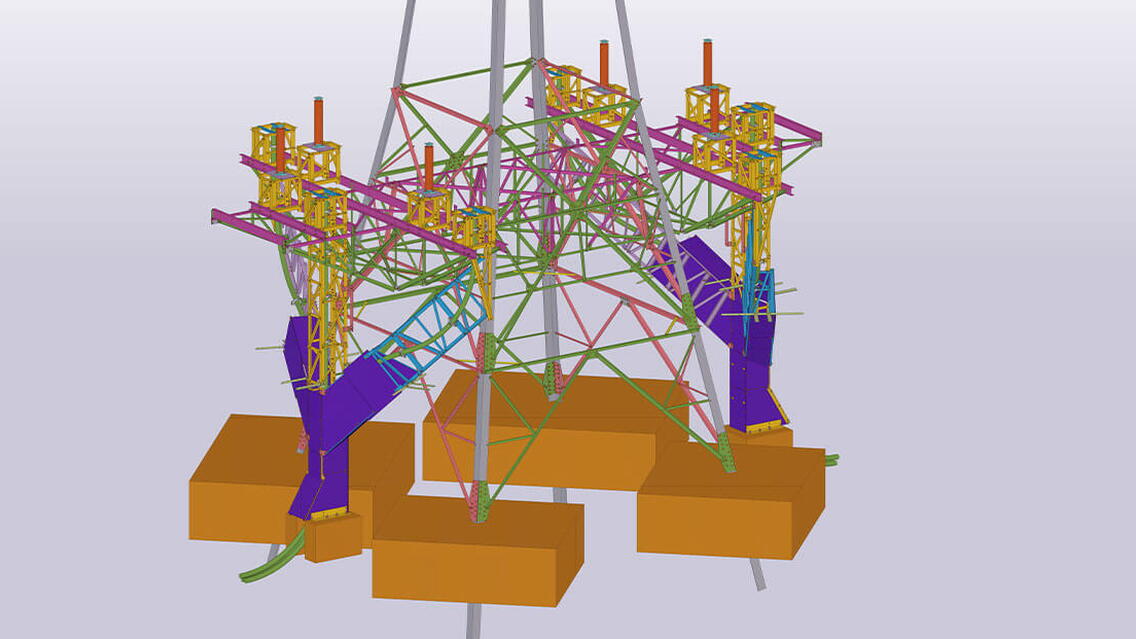

The project was supposed to be a quick replacement on an existing cable ladder with 3 legs for new sealing ends however, after a site visit it was noticed that pad foundations were used & not the normal foundations used. This meant where 2 of the new ladders were supposed to be going couldn't be installed because of the existing pads clashing. A symetrical plan became a problem when clashing was sotted early on so an asymmetric design was used. Luckily in Tekla we could use the polybeam tool to draw out the cable & its min bend radius to make sure we could fit the cable & the new ladder around it. Client specifications also meant we had to create a bespoke anti climbing device & install a box from ground to 2.6m as the tower was open to the public. Working with our cabling team we were able to obtain the cable clamps being used in IFC format & import them into the model again to ensure the cable would fit & we could detail steelwork around this.

We also had to ensure the new foundation also missed the existing pad so using drawings from the 1940s when the tower was installed we managed to do this. the tower is also an old imperial tower so again drawings from 1940s which had been scanned into the system had to be used to model the tower & platform which has its own issues with some parts being unreadable.

We used Trimble Connect a lot on this project with the project team to keep everyone updated on changes & to ensure the design were happy with the proposals. This project is the 1st time we have trailed QR codes on drawings to give site full access to the models for use on site which from feedback we have had has been very worthwhile. The project is due to be built at the end of May 2021.

What were the challenges and what are you most proud of about the project?

Pads used as foundation rather than normal foundations at least 2m underground so we had to use a trefoil cable ladder design. The proudest part for me was using the QR code for the site and project team to see the model and raise any issues they could see with installation and help with installation.

What benefits did utilizing BIM and Tekla software bring to the project?

Using Trimble Connect helped massively, all the team could see the model when they wanted from our link provided that would update every time I uploaded the model. Team meetings because easier as everyone could see the model & raise issues before they happened on site saving hundreds of hours on site & huge cost saving. There were that many bars out of plane in the job that 2D would have nearly been impossible to create drawings for, we would have needed plain bars for site to drill and cut themselves so using Tekla saved on labour on site.

The project in numbers

- Steel and bolts used on new ladders (2 total one on either side) - 4900kg

- Concrete cubic meters - 4.02m³

- Rebar used - 295kg

- 7m tall 8.5m wide

- Detailing hours around 400

- Hours saved because of Tekla = thousands