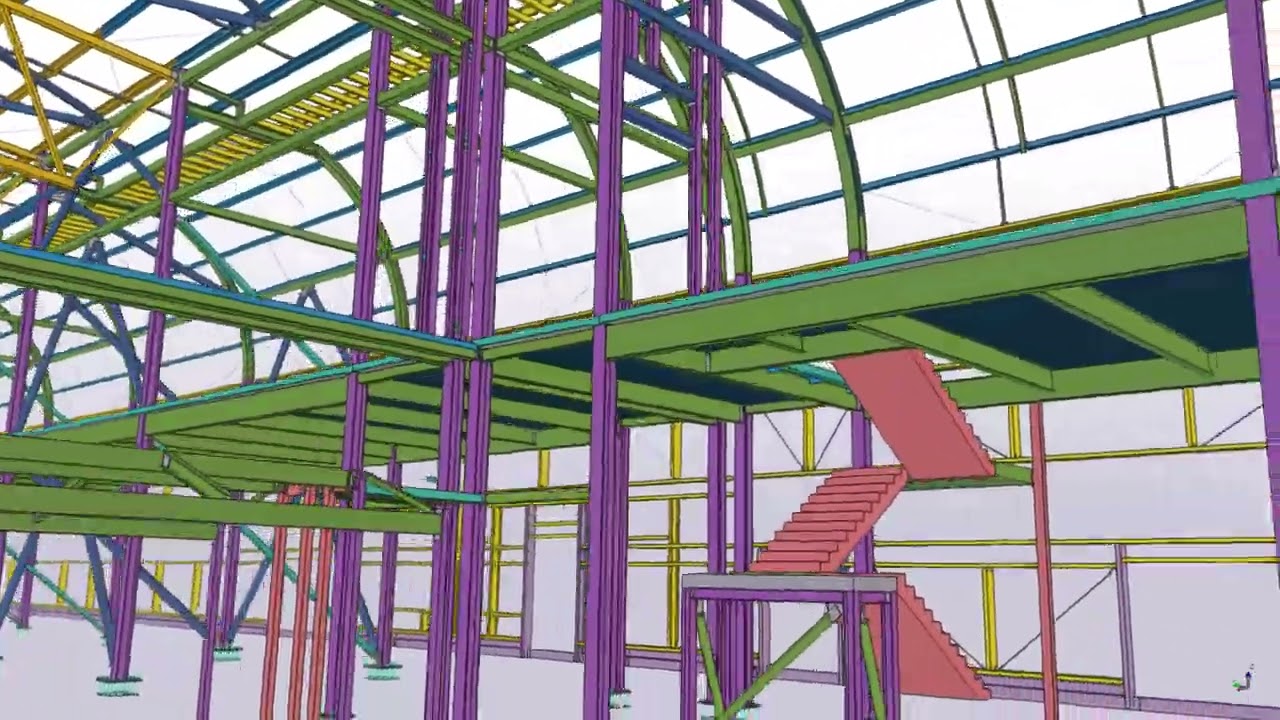

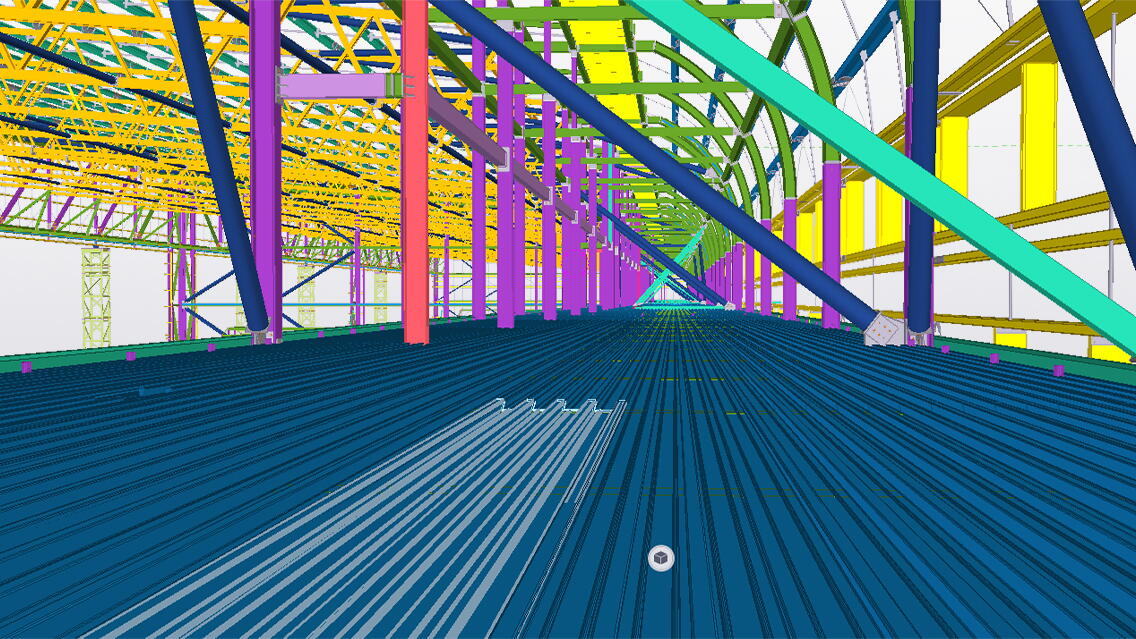

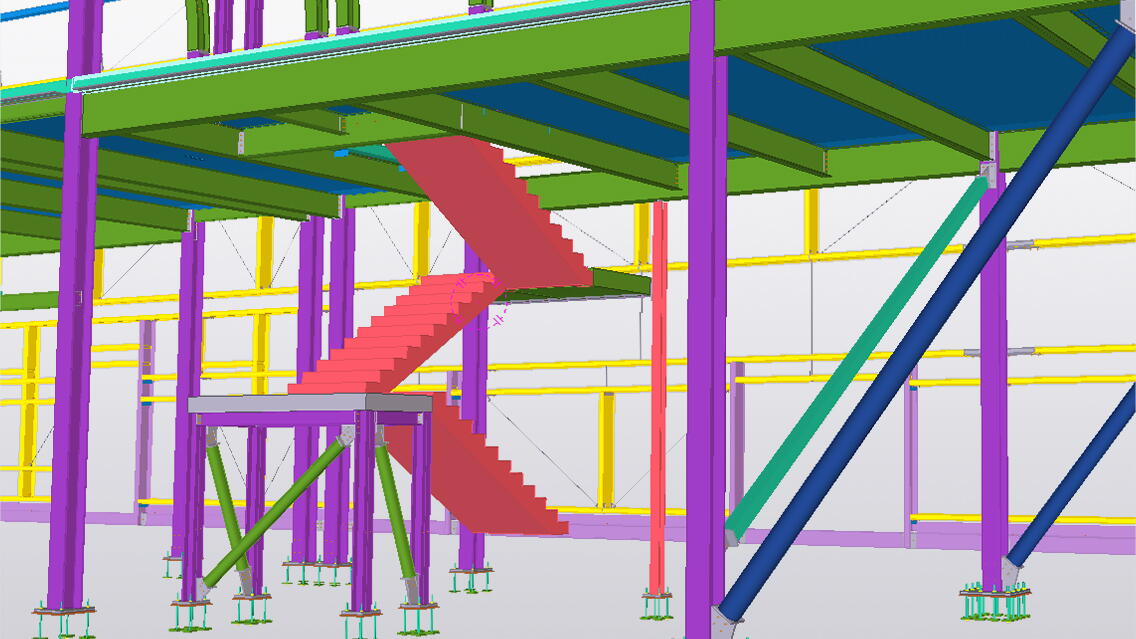

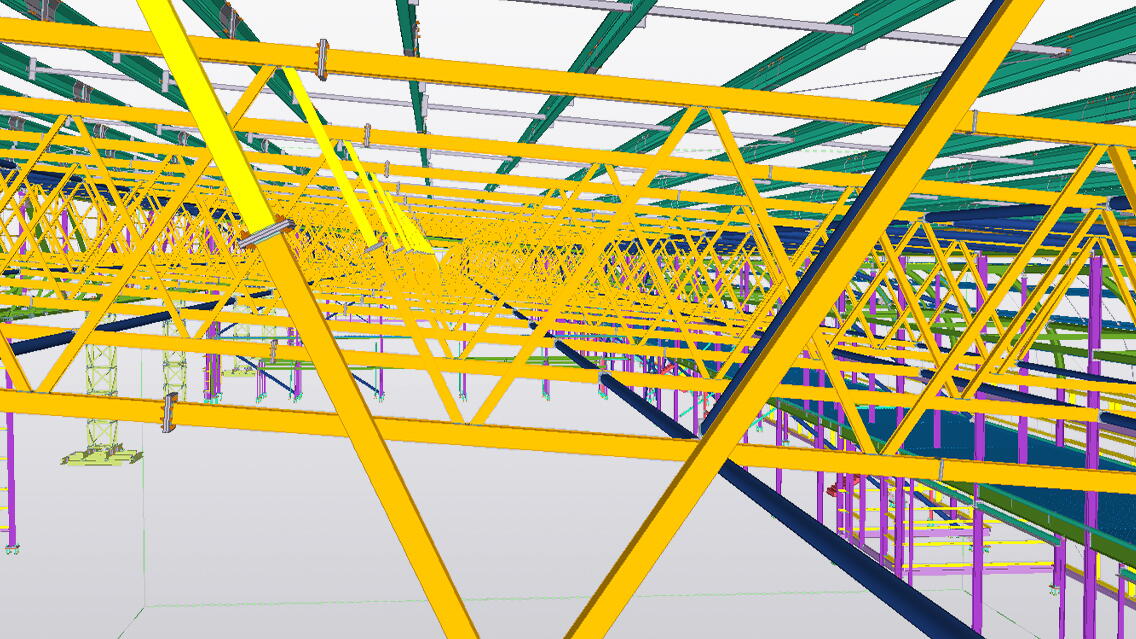

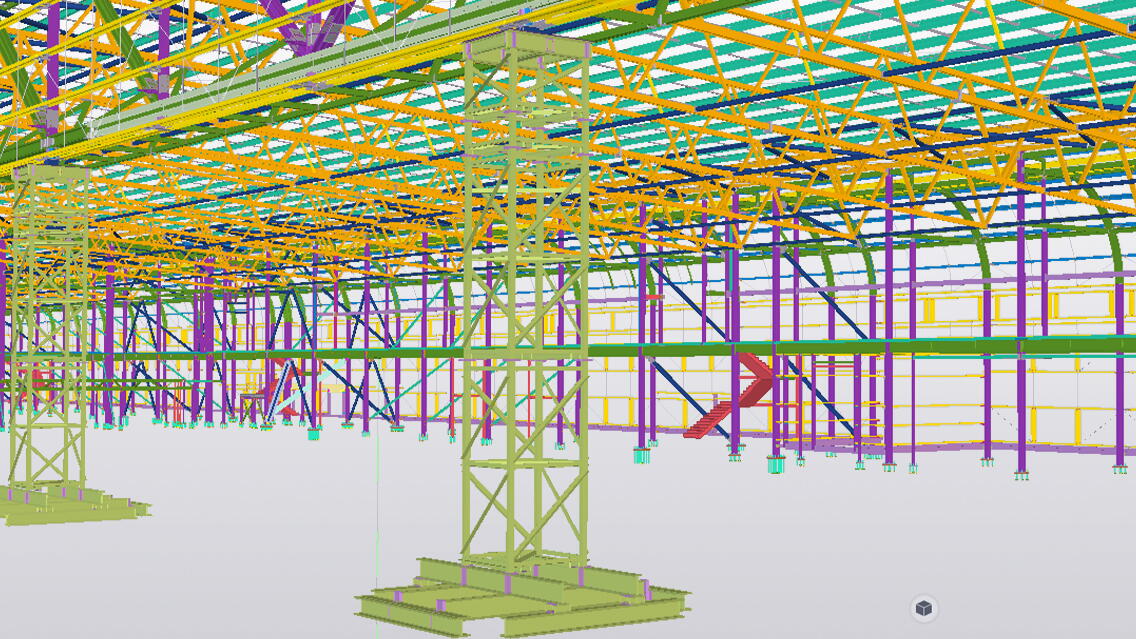

Farnborough Airport's latest development includes an aircraft maintenance hangar designed to meet the luxury flight services and aircraft servicing needs of the airport. The hangar features a spacious interior, achieved through large primary trusses spanning over the hangar doors and supported by numerous secondary trusses for roof support. The project's unique aspect lies in the impressive size of the hangar doors, boasting clear openings of 10 meters in height and 70 meters in width. The structure's design, including the curving lower eaves, reflects the luxury services offered by Farnborough Airport.

Challenges

The project encountered significant challenges in coordinating various aspects such as: structure, cladding details, doors, and louvers. However, incorporation of these aspects into the Tekla model enabled problem-solving during the design stage, eliminating surprises on-site.

Achievements

- Using Tekla Structures for accurate detailing and generating CNC data, including torque wrenches for TCB connections.

- The use of Tekla's API played a crucial role in automating tasks, such as: steel validation, hole checks, custom pop marks, lifting hole creation, and erection drawings, streamlining the entire fabrication process.

- The coordination of temporary works, specifically propping and jacking of primary trusses during construction.