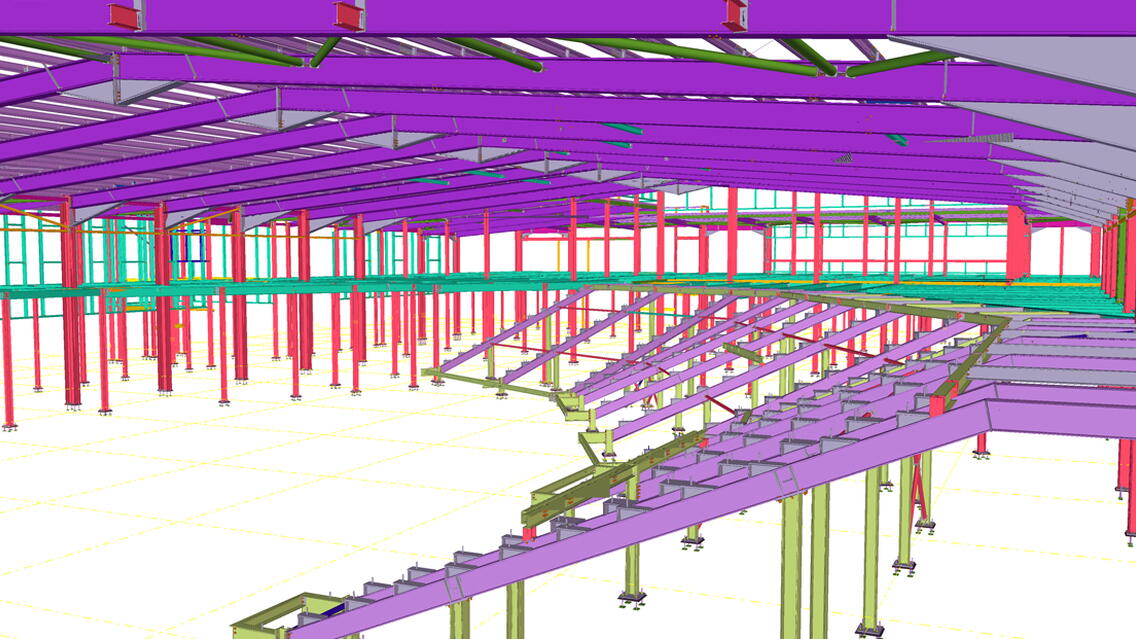

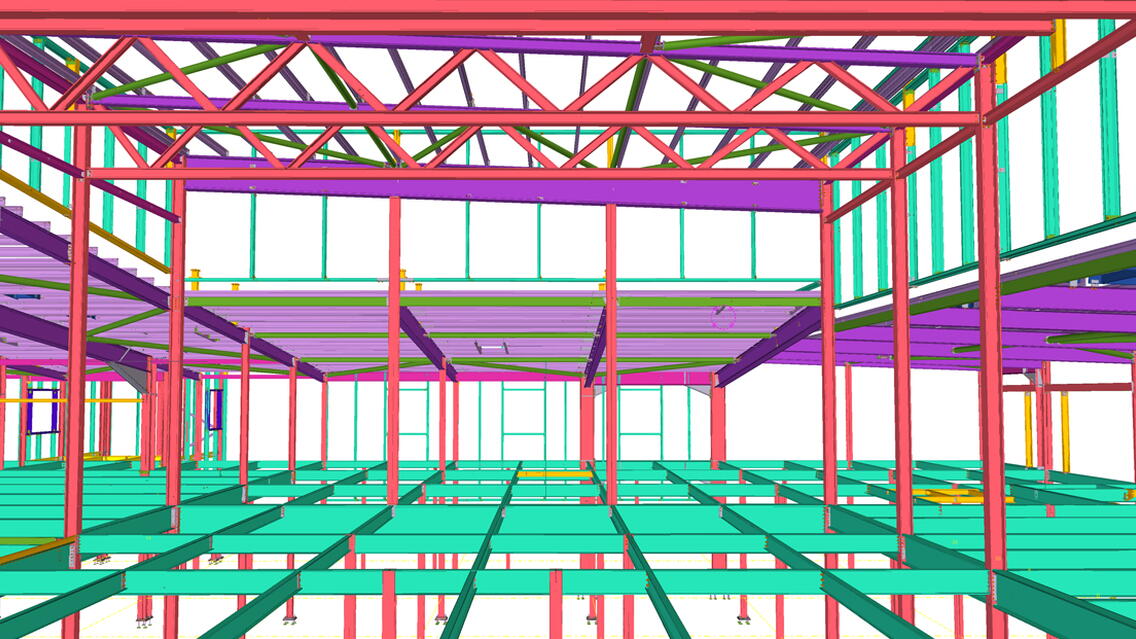

The Green Pastures development will have a church, business park, training centre, social and student houses, a nursing home, and retail premises. The steel framed building will include a state-of-the-art 1650 seat main auditorium, as well as many exciting community facilities including a gym, children’s indoor play area, fully equipped sports hall, café, restaurant, informal meeting zones, specialised youth facilities, and a Wedding & Reception Venue.

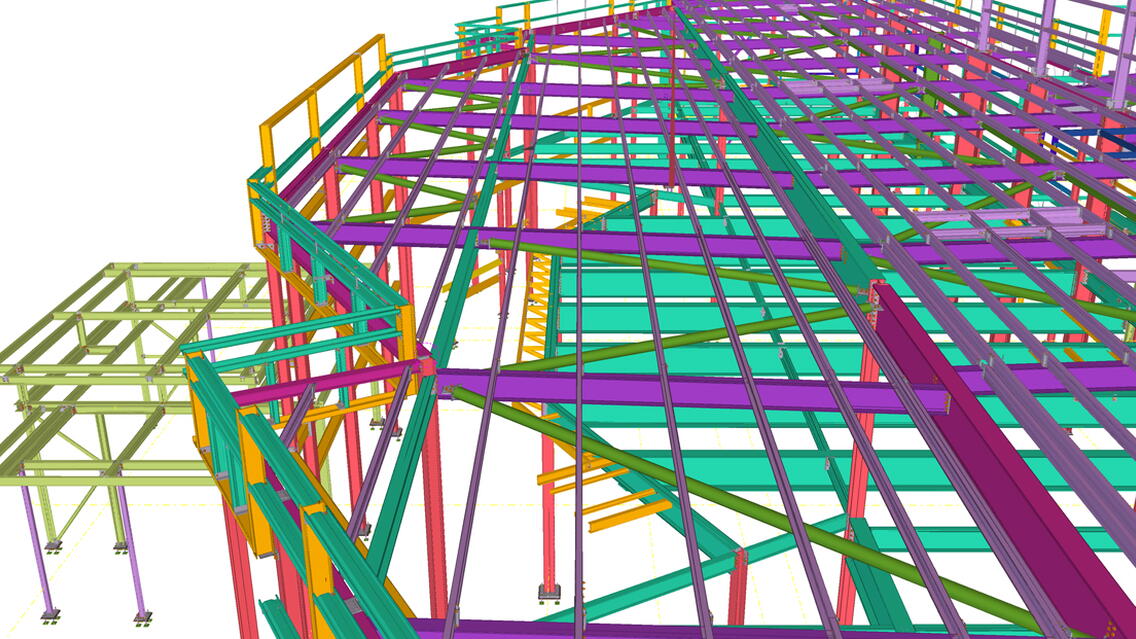

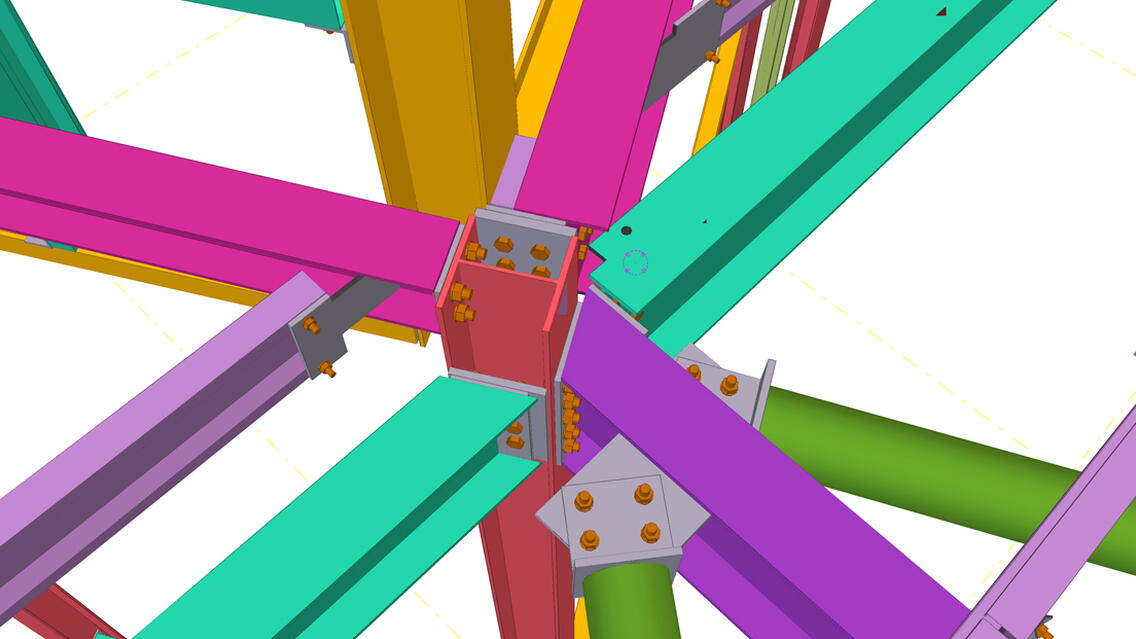

The project was split into four main phases with each phase divided into two sub-phases to suit the erection schedule. AMCA Structures Ltd. was responsible for the modelling and detailing of the steel frame (hot rolled and cold rolled members) as well as issuing general arrangement drawings to the Design Team, fabrication drawings and relevant documents required by the Steelwork Contractor as well as all the necessary steelwork erection drawings.

All of the project's structural steel was erected by end of March 2018. The project is planned to be completed by end of 2019.

What were the challenges and what made the project successful.

The main auditorium roof is formed by a series of 23m long rafters, spliced together at mid-point, to create an overall 46m clear span. The double height sports hall is formed with a series of 18m long by 2m deep trusses. Complex geometry and the very long spans as well as the variable heights of the perimeter parapets and different cladding specifications required excessive coordination between the steel detailing team and the Architect's / Structural Engineer's team throughout the duration of the project. The detailing team was involved not only on the modelling / detailing process but also on any design issues that would arise due to the building's geometry.

What benefits utilizing BIM and Tekla Software brought to the project.

IFC models were used from start to finish in order to ensure that the steel structure would combine without any issues with all the architectural features. IFC models issued by the architects / precast contractor were compared with the IFC for the steel frame thus making it easier to identify any problematic areas.

The project in numbers

Total hot rolled members tonnage: 705 tn. Total cold rolled members tonnage: 39 tn. Longest continuous member: 23m. Heaviest member: 7tn.