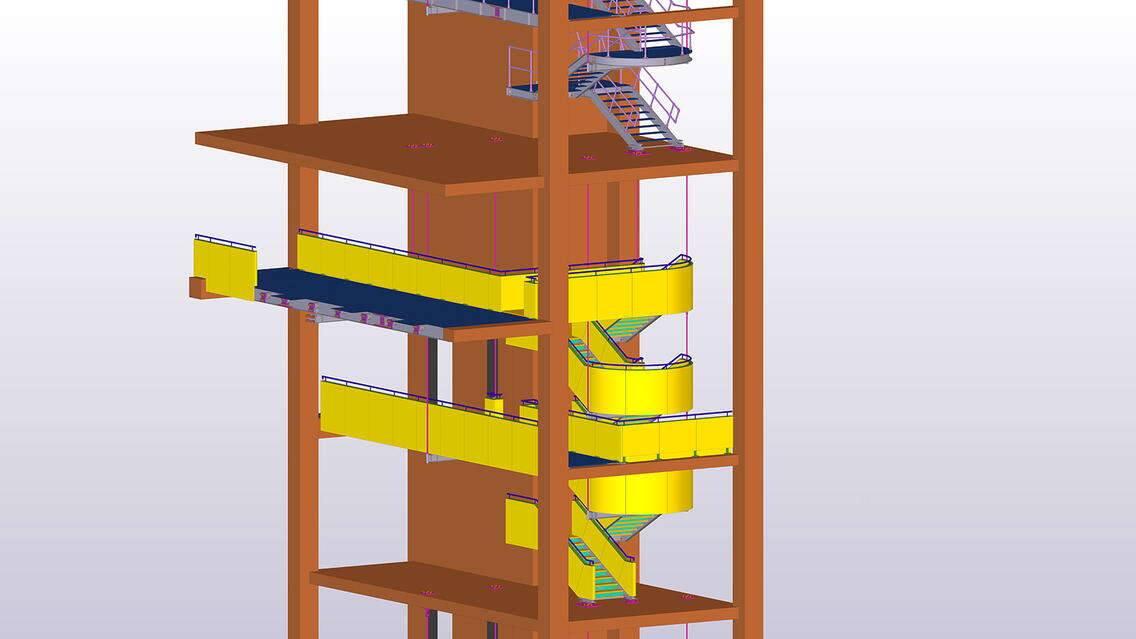

Atrium stairs for new Guy’s Hospital cancer treatment centre

TDS undertook the modelling of five atrium stairs to each 'village' at the new cancer treatment centre at Guy’s Hospital London. Each 'village' relates to a patient’s particular need - chemotherapy, radiotherapy, one-stop clinic and so on with access to each village via lifts.

Once in the required ‘village’, the patient navigates through the non-clinical space on the bridges and staircases. All the stairs to the public areas follow a similar design of a steelwork skeleton clad with birch ply - including treads, finished with stainless steel handrails and glass risers. The stairs are supported from the concrete floor above on tie wires and fixed back to the bridges.

How we used Tekla

Using Tekla we modelled the structure accurately from a number of materials using classes, object representation and surface treatment to create the correct differences in items. One of these points was to differentiate between left hand and right hand threads on the tie wires. We used object representation to change the colour of the left and right hand threads whilst both items were modelled the same, had the same numbering prefix and same class. Using 'left' or 'right' within user phase we could apply these settings and give the items separate numbers.

All the stairs and bridges have been clad in birch ply. Using surface treatment we ensured that panels were handed and orientated correctly so that the face and direction of the grain of the ply ran on each panel. This eliminated any manual notation on panels and ensured we didn’t get any errors with the birch ply - an important factor given the lead-time on these items.

3D PDFs aided architect’s client communication and on-site logistics

Using Tekla we were able to show the architect true visualisations of key details as we developed their design into a workable solution. They were particularly happy with having 3D PDFs provided to them of stairs so they could orientate and discuss with the hospital trust to ensure the client was happy with the stair design. We also used the same process to help other trades – namely M&E services which had to run their items through the bridge structure.

Using a common datum we provided IFC copies of our model to the main contractor so they could ensure the co-ordination between the stair and the concrete lift shafts, which had anchors cast into the walls. This process was then repeated when we were provided with an as-built model of the anchors. At this point we discovered some anchors were out of tolerance and we were able to adjust our fixing back to the concrete detail. To do this at the drawing stage rather than on site demonstrated the benefits of sharing models between trades as schemes are developed. It certainly helped to minimise any site complications or difficulties.

Due to the low strength of the surrounding structure and slabs we had to be careful during erection not to overload any of the supporting structures. With Tekla we could co-ordinate with the site team easily to provide lifting weights of individual beams and bolted assemblies including centre of gravity so that they could ensure they had suitable lifting equipment positioned in the optimum position.