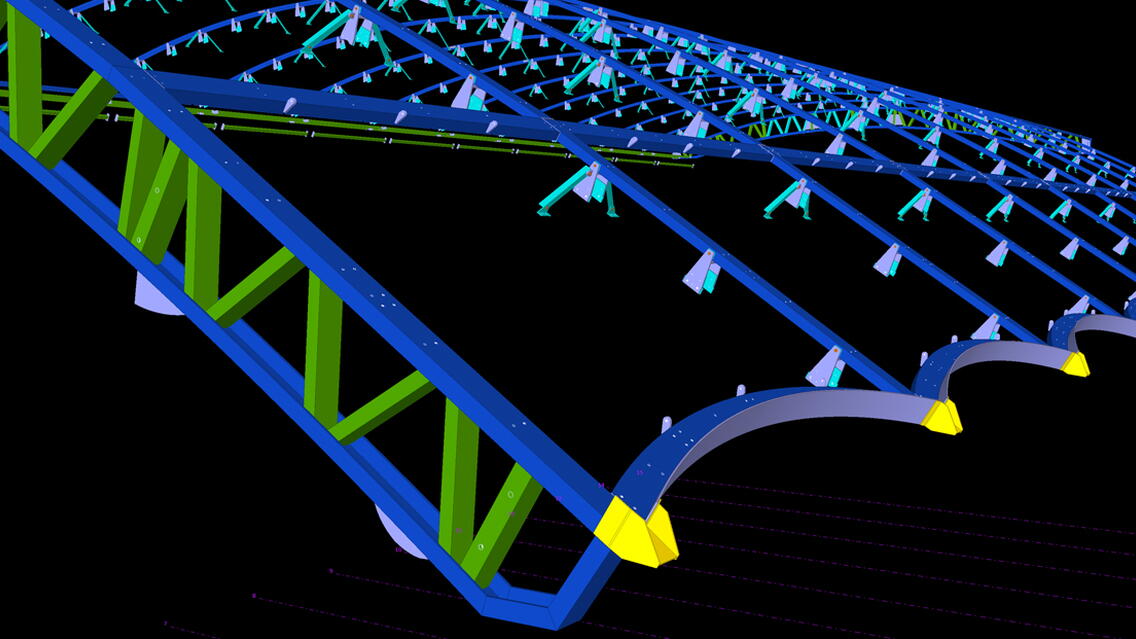

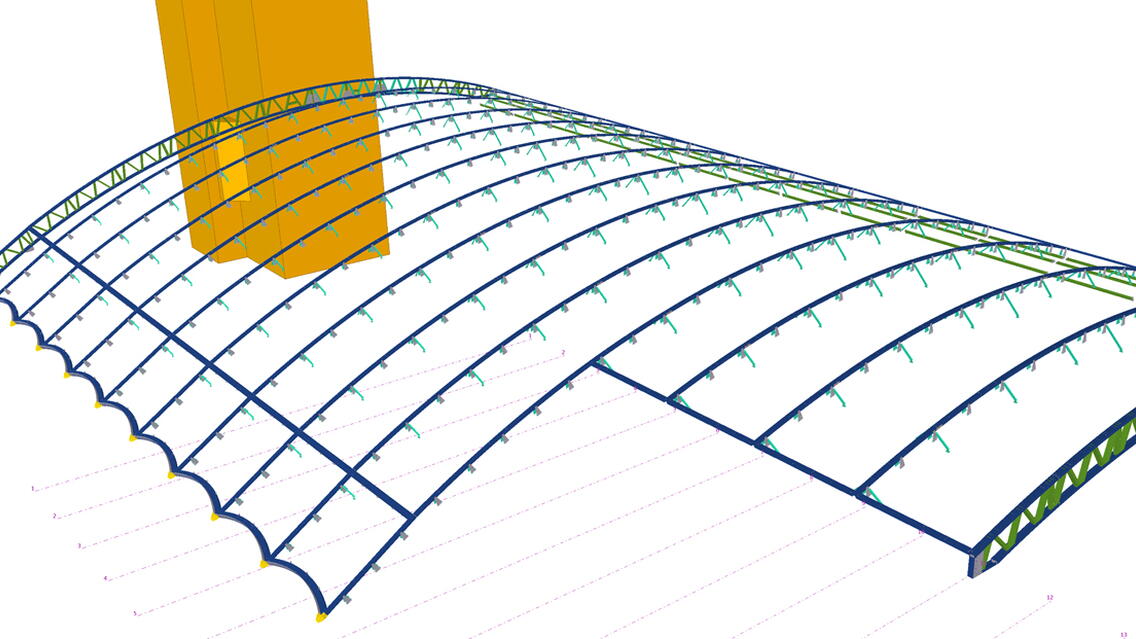

CambridgeHOK main scope of works was to replace the existing gable glulam rafters which was damaged due to severe rot. They have been replaced with a multi-radius curved tapered lattice truss (Steel). All intermediate glulam rafters have been bolted with curved PFC to allow the roof height to be raised to suit the new ETFE system.

CambridgeHOK was instructed to detail, fabricate and install all structural steelwork on the project ready for the installation of the ETFE system by Access North Ltd.

What were the challenges and what made the project successful.

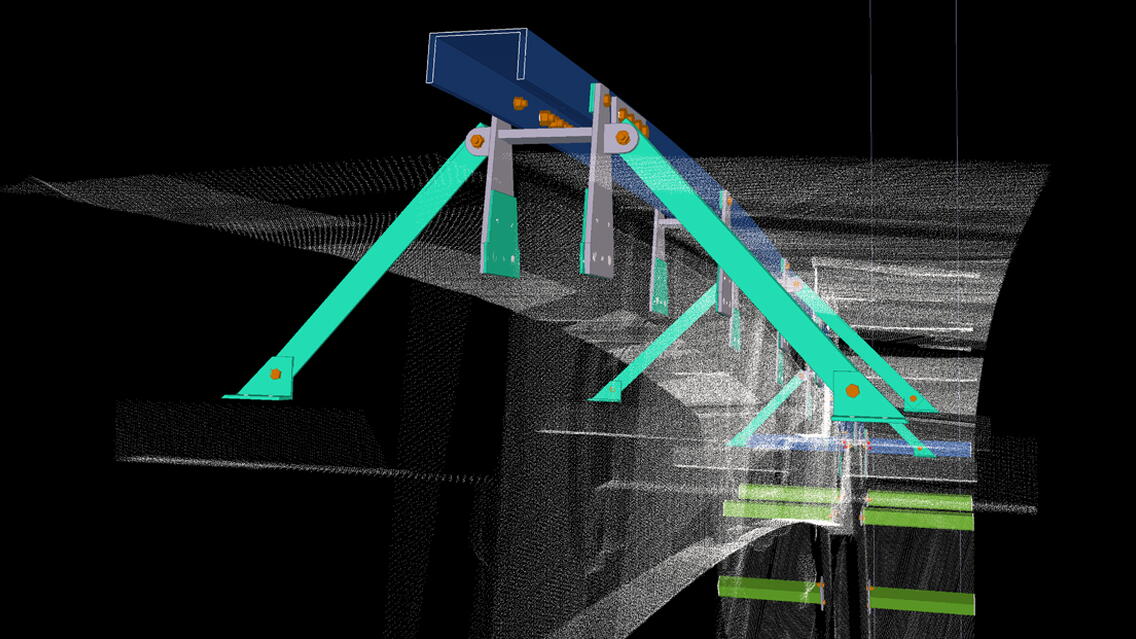

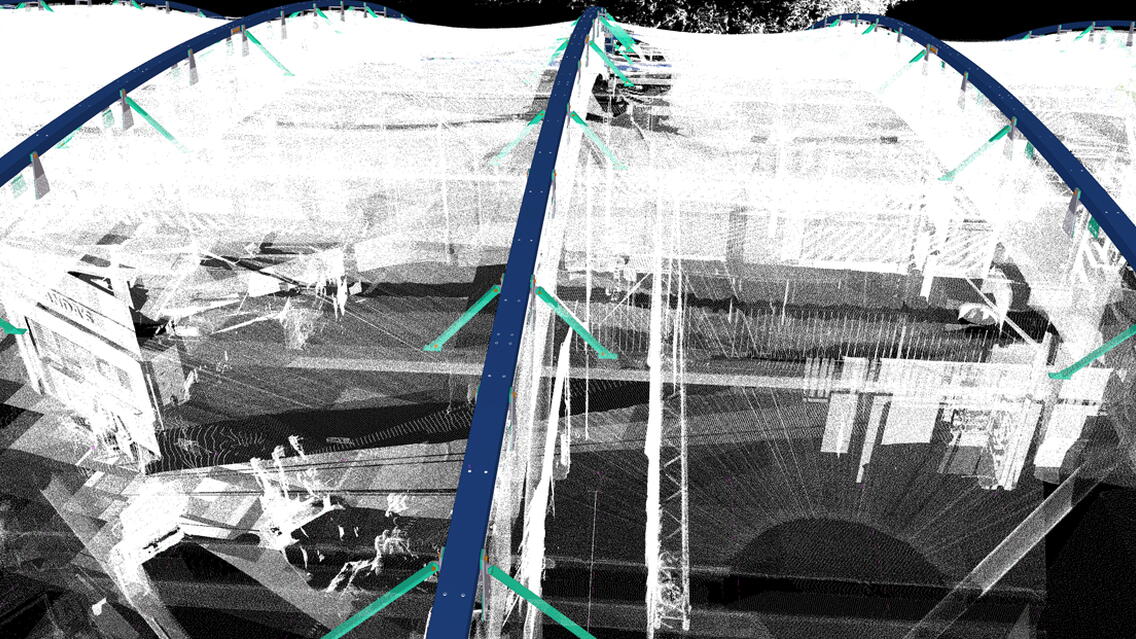

Challenges on the project was to match the existing structure, with each glulam with its own unique dimensions. With no access to the glulams during design stage, we utilised a 3D scan of the site which the design was based on.

What benefits utilizing BIM and Tekla Software brought to the project.

Thanks to Tekla Structures 2018 with its point cloud import feature, this allowed us to import the entire 3D scan into Tekla Structures without purchasing additional software. In addition we was able to model all steel work over the point cloud without having to export to a 3rd party BIM software for clash checking.

The project in numbers

Point cloud reference (.e57) = 1,410,065,408 points. Length of building = 52.5m. Width of building = 34m. 17.17 tonne of steel (Not including temporary works). 80 Assemblies.