The University of Glasgow’s new £90.6m James McCune Smith Learning Hub is an inspirational and diverse learning space, allowing both undergraduate and postgraduate students access to state-of-the-art learning spaces.

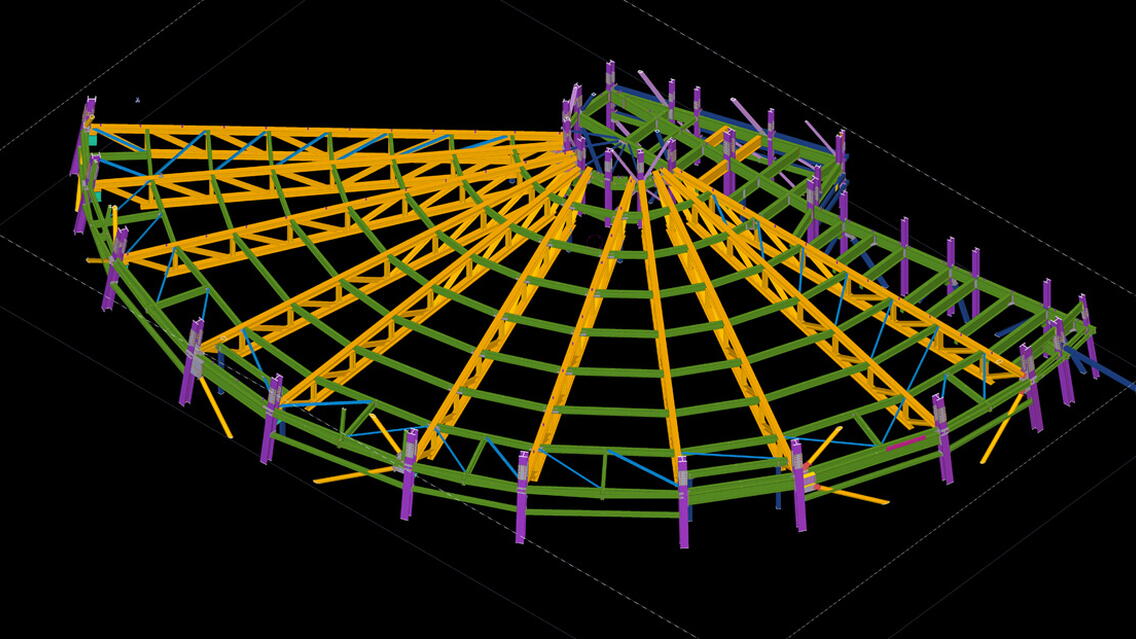

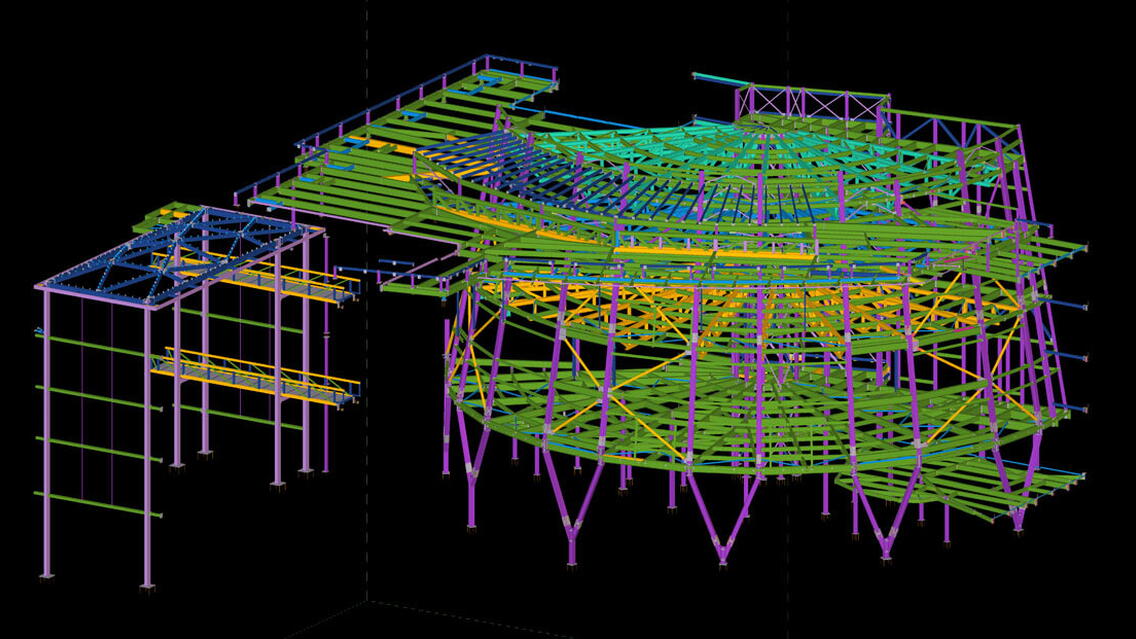

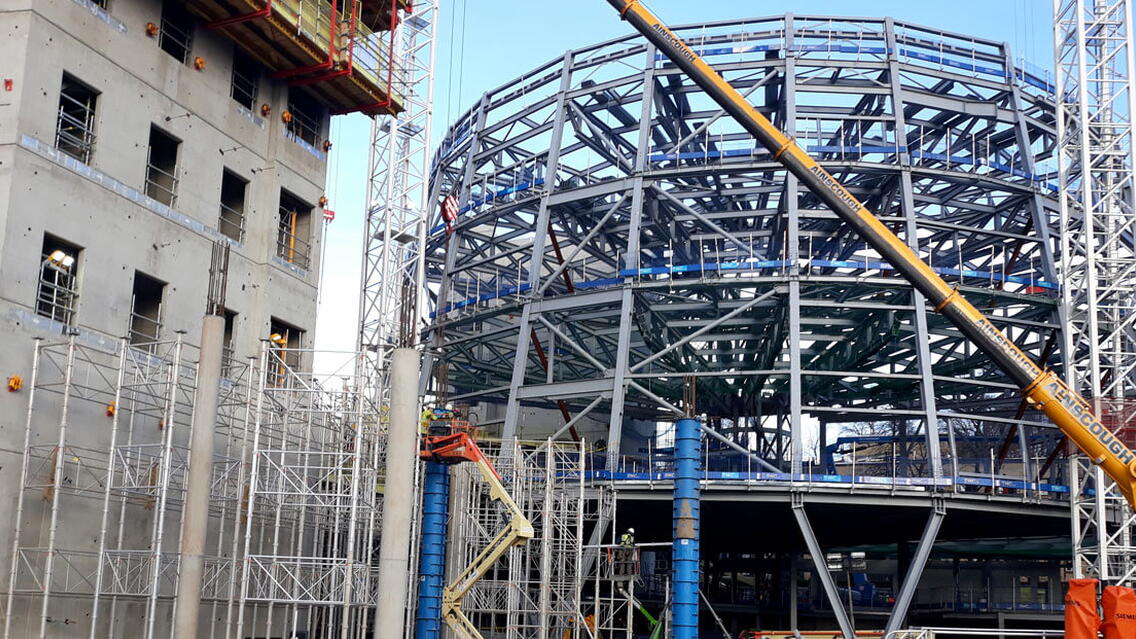

The 16,640m2 flagship development consists of 950 tonnes of hot rolled steelwork, forming the eight-storey building comprising of an in-situ concrete frame with steel-framed structure. Externally, the building is clad with curtain walling, precast panels and weathering steel. The upper lecture hall floors are arranged on a radial grid 27m primary spans. For this reason, light-weight steel construction was used in place of flat concrete slabs used for the general floors.

The building will accommodate over 2,500 students, including a lecture theatre with capacity for 500 students. Interactive teaching spaces will range in size from 340 – 75 students, while the hub will also have several seminar/group study spaces.

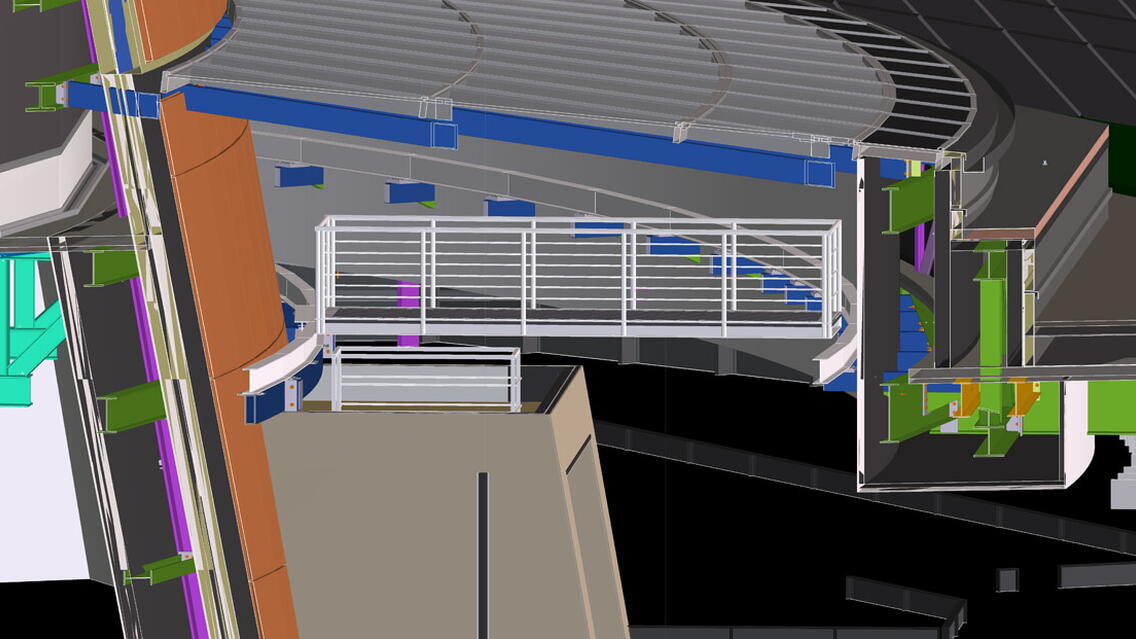

BHC Ltd. were responsible for the full detail, fabrication and erection of structural steelwork and the supply and installation of metal decking including shear studs and combisafe edge protection. During the project, we collaborated with the Architect, Engineer and Novum (Glazed Roof Contractor).

What were the challenges and what made the project successful?

- Keeping control of changes by the design team, tracking these through our system and catching the changes before the steelwork was delivered to site.

- Ensuring the best method of erection for such a complex structure.

- The use of point cloud technology helping to collaborate with site and improved information flow.

- Maintaining continuity in the detailing and fabrication of all 33No. trusses.

What benefits did utilizing BIM and Tekla software bring to the project?

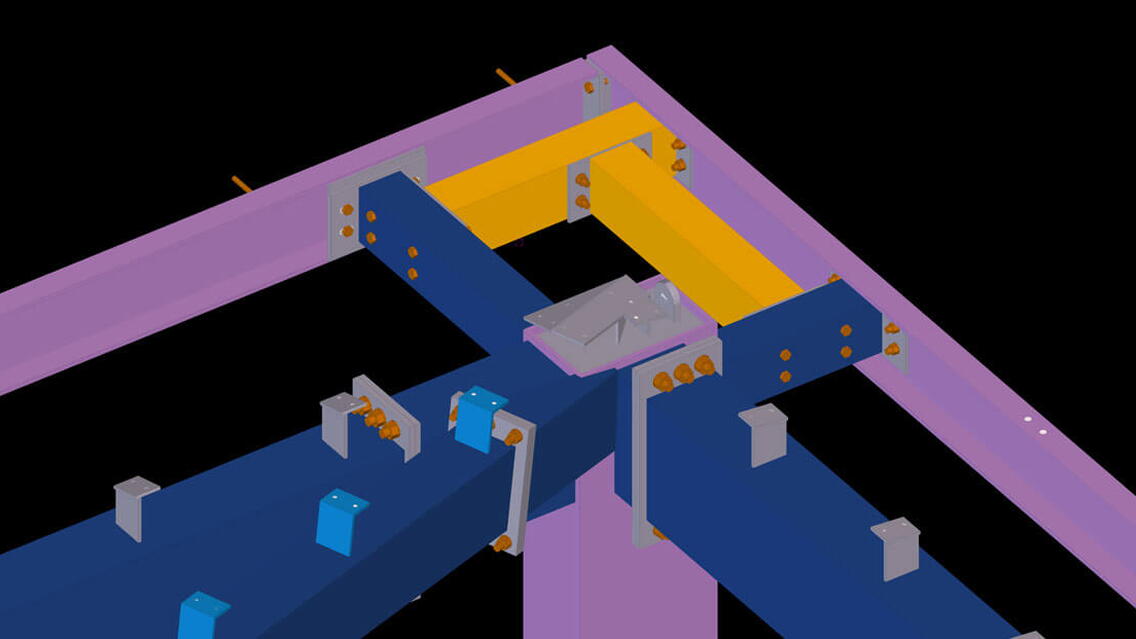

- The unparalleled accuracy of Tekla software ensuring consistency right from the 3D model, through to fabrication and then to site.

- Using Tekla as an information collaboration tool allowed us to see any potential clashes with the existing structures, secondary steelwork and cladding. These could be resolved before becoming an issue on-site.

- Through the use of IFC's from the architect, consultant engineer, cladding supplier etc, we could process these with the 'Change Detection' tool, which would let us see any changes on a week by week basis. This was invaluable for keeping the workshop on schedule and in turn, the site too.

The project in numbers

- Total cost - £90.6m

- Hot rolled steel - 980 tonnes

- Metal Decking - 5,400m2

- Erectable Hot rolled pieces - 1820