Kumasi Central Market is a major trading centre in the Ashanti Region which is visited by up to 800,000 people daily from Ghana and the surrounding countries of Benin and Togo.

BHC Ltd will be fabricating over 8,000 tonnes of structural steelwork in our 55-acre fabrication facility in Carnwath, South Lanarkshire which will then be shipped from Grangemouth to the Port of Tema, Ghana in containers. Approximately 60% of the electricity used to fabricate the steelwork will be generated by BHC’s onsite wind turbine, and the heat within the fabrication facility is produced by 13 biomass units. The shopping centre is designed to promote economic growth, to boost tourism and to encourage socio-economic development by improving connections to the North of Ghana. The market will feature 6,500 market spaces to lease, 5,400 cold stores, 800 kiosks, 50 restaurants, 210 stalls for fishmongers and butchers, 40 livestock stalls, a police station, fire station, post office and a hospital.

Key challenges overcome during this projects

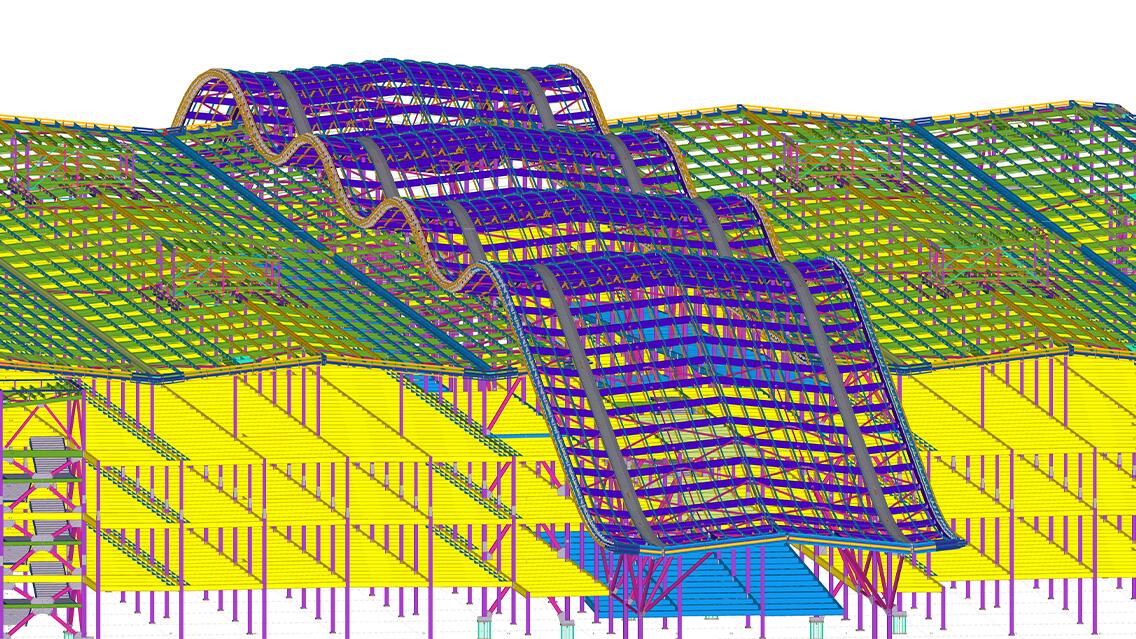

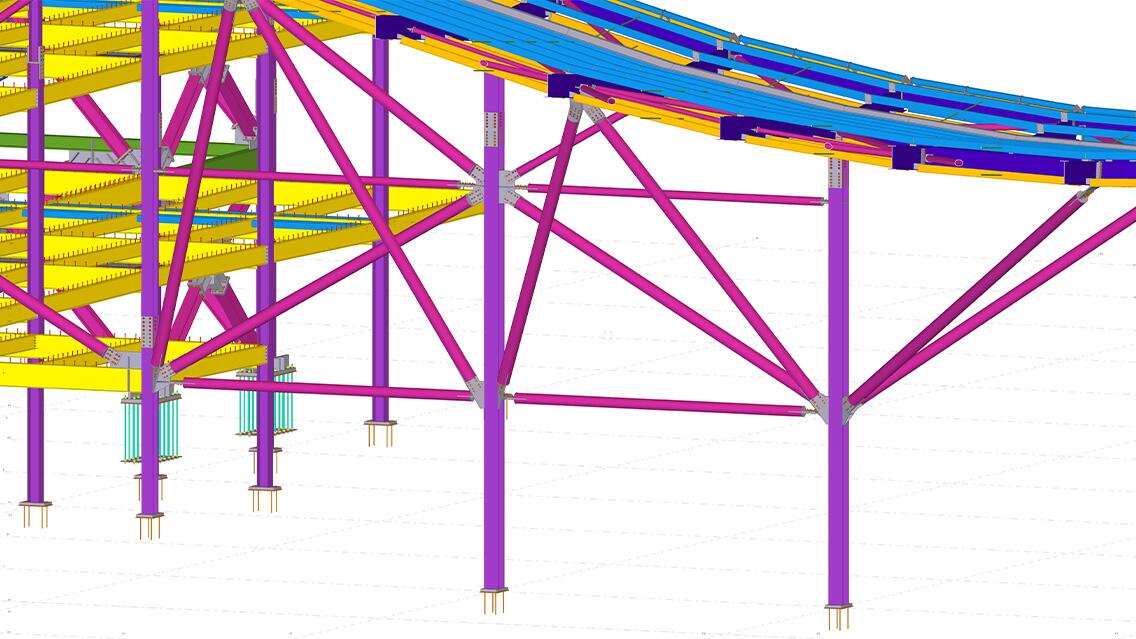

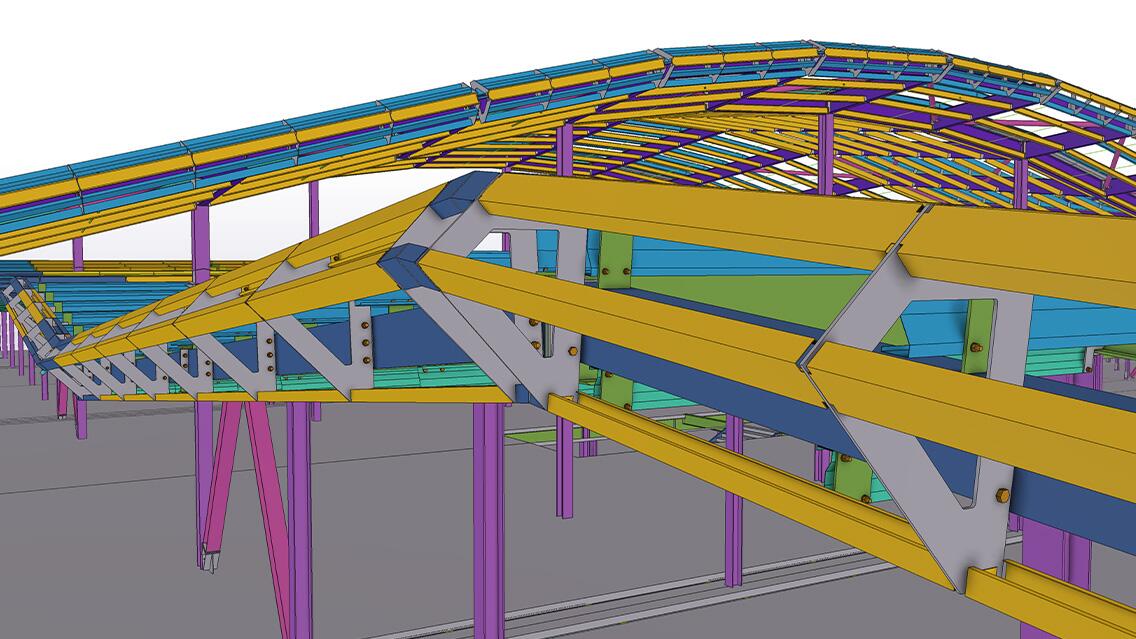

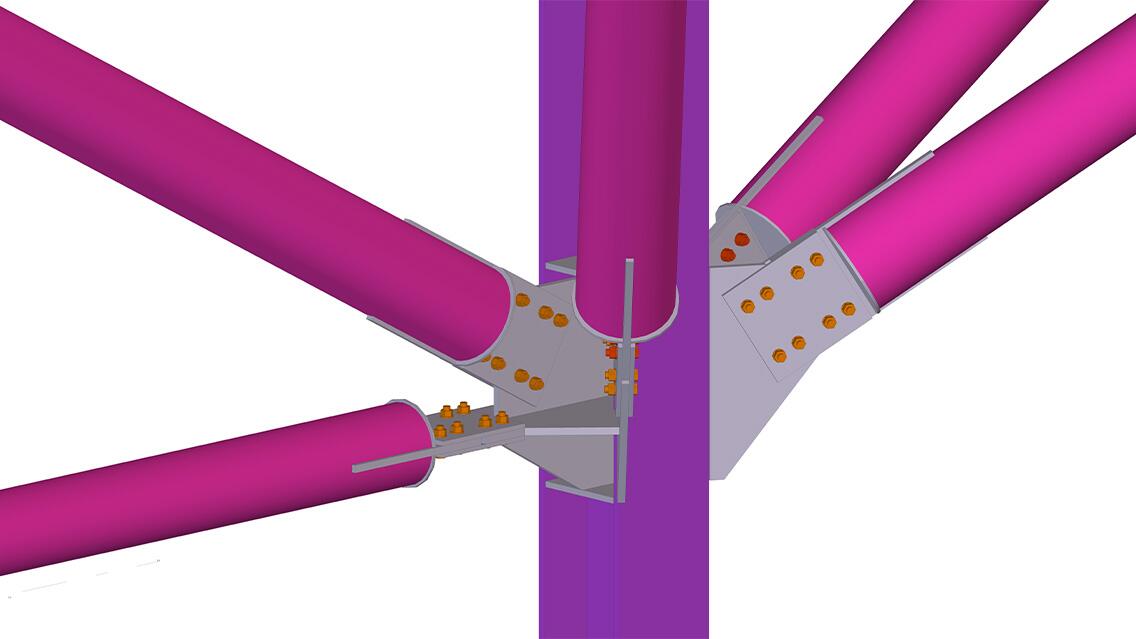

- The design and detailing of the bracing for the high seismic loadings

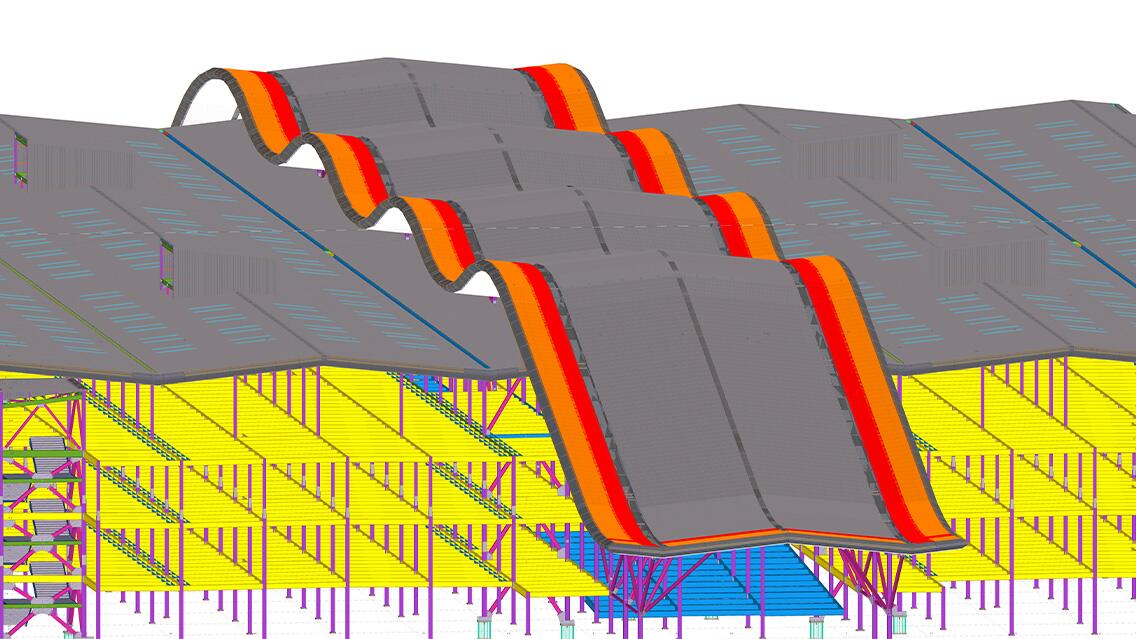

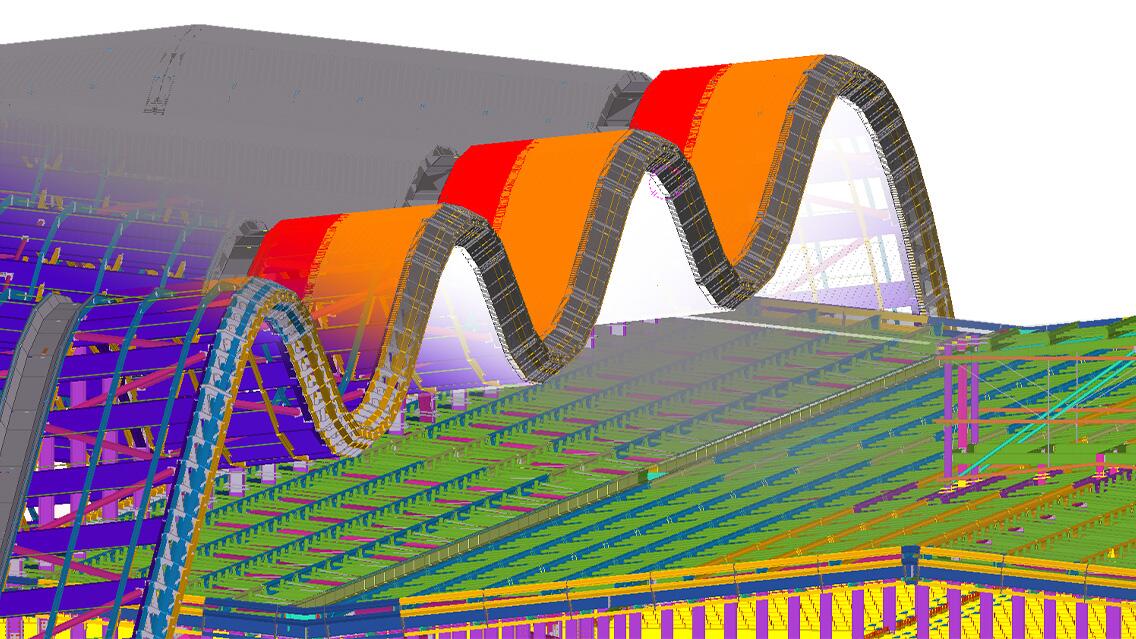

- Detailing of the hot rolled, cold rolled and cladding materials for the ‘wave roof’

- All the steel had to be shipped in containers so the size and detailing of the members had to always be kept in mind

- The bullnose cladding detail with d-frame support was originally designed as a welded 127UB frame. This detail was going to be very costly and time consuming so BHC designed these frames as flat plate which could be profiled from plate

Key benefits did of using BIM and Tekla software

- The Trimble Connect model was shared with various external parties which helped greatly with the development of this project.

- Due to its size, the cladding was detailed in a separate model. Running an IFC reference model to use in this model was a great help!

Important points or benefits:

- Hot Rolled: 7980 tonnes

- Cold Rolled: 350 tonnes

- Metal decking and cladding: Over 100,000m2

- The Trimble Connect model has been supplied to parties during the detailing process, which was used in weekly design team meetings, also all site teams have access to the model to aid with erection