Leicester City Football Club is home to one of the most advanced training centres within Europe. BHC supplied, detailed, fabricated and erected the structural steel as well as the installation of metal decking, edge protection, off-site fire protection and concrete upper floor slabs on the project.

The King Power Centre is the site’s most prominent structure. The spectacular dome, built into the landscape, houses an air-conditioned, artificial pitch and a media centre including a press conference room, broadcast facilities and hospitality space.

The steel-framed building is set within a gently sloping earth embankment that blends seamlessly into the surrounding landscape. Structural steelwork is played a leading role in the project, not just in the construction programme, but also in its design aspect.

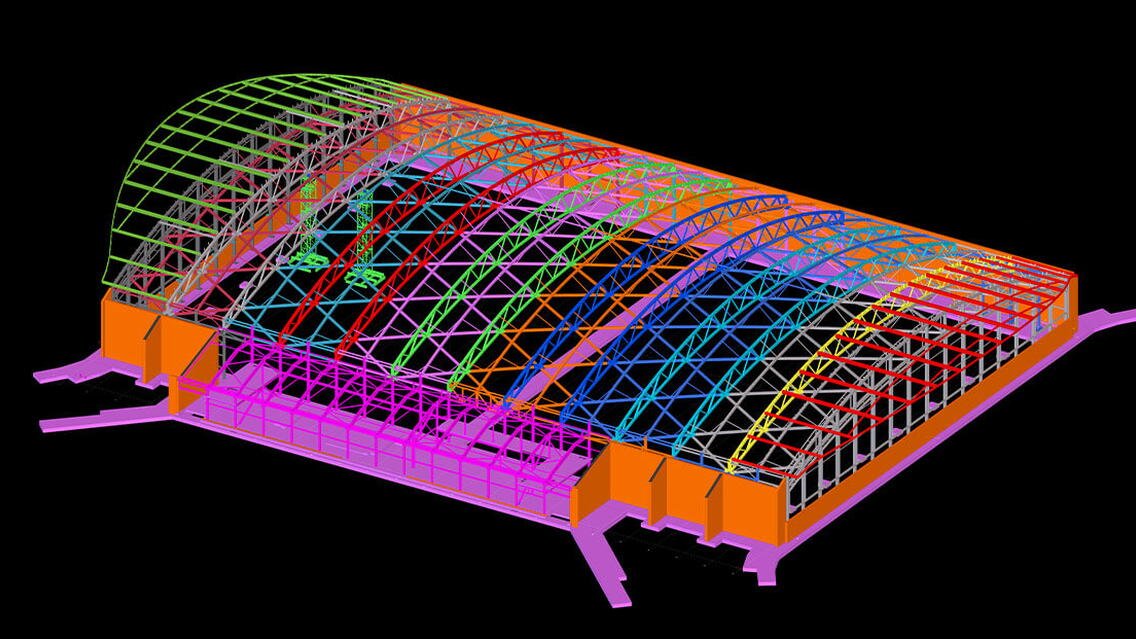

The large domed structure that houses the in-door pitch offers clear spans of 80m x 122m. This was achieved by using a series of 13 arched steel trusses, set at approximately 9,3m centres, supporting a box section steel diagrid and a series of intermediate arched rafters set at 4.65m centres.

The first training session for Leicester City Football Club took place on the 24th of December 2020.

What were the challenges and what made the project successful?

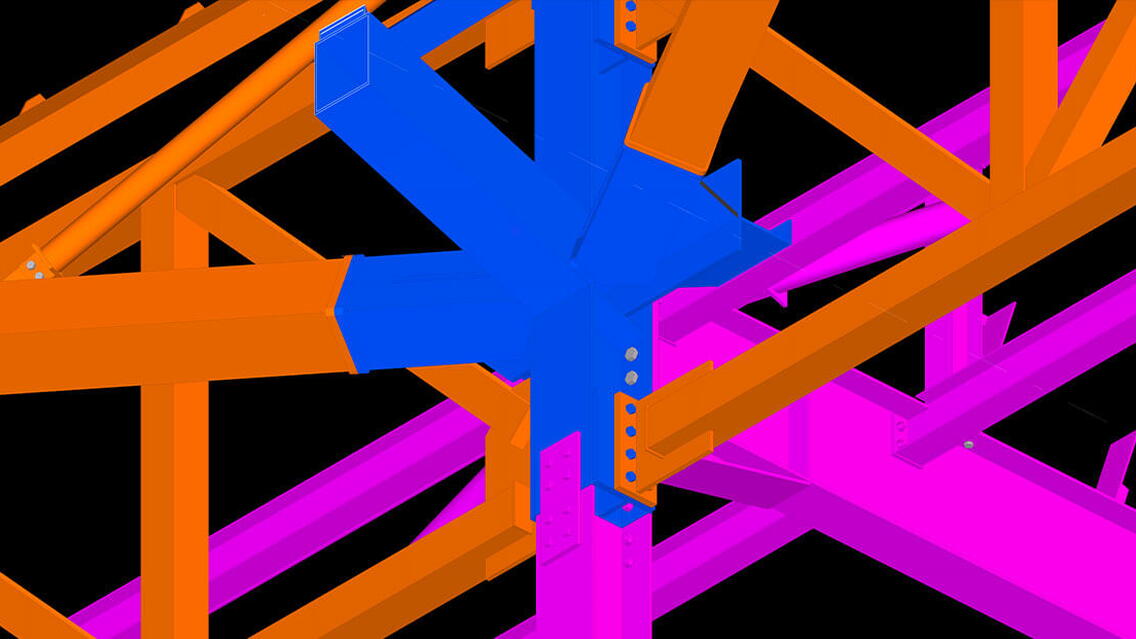

Achieving virtually hidden connections on the indoor pitch diagrid roof, to create the desired ‘Full Assembly’ visual.

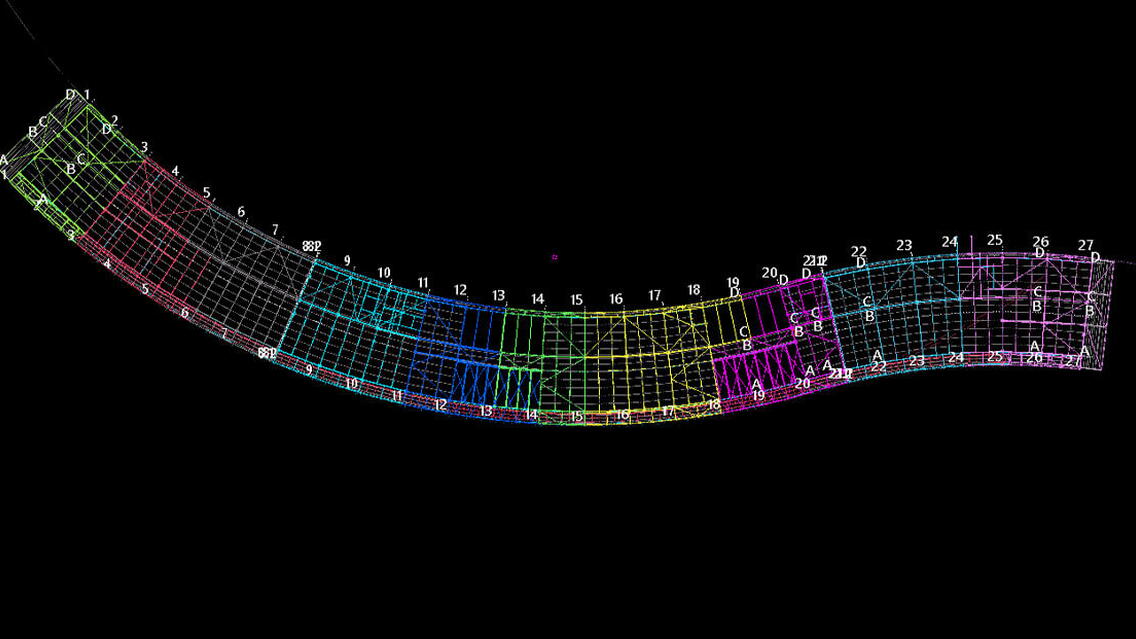

Fabrication, transport and erection of 80m span trusses in 4 x 20m sections. To achieve this SHS top and bottom booms were purchased in long lengths > 19m and then rolled to a curve before being delivered to BHC for fabrication. These were on the limit both in terms of steel mill and rolling machine capabilities.

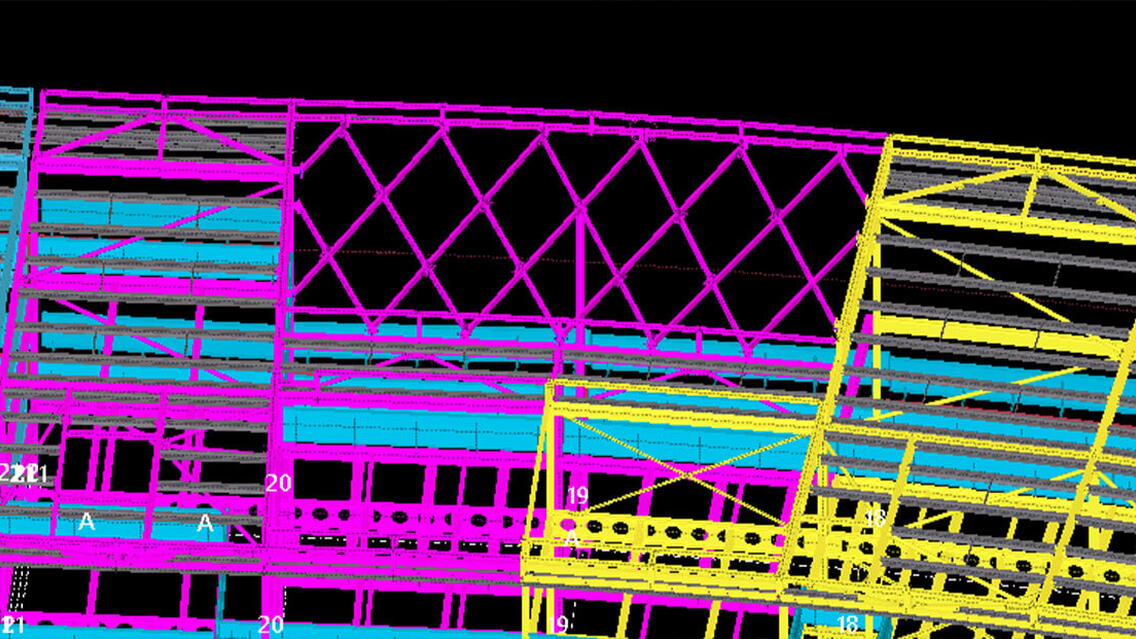

Devising a suitable erection sequence including temporary works taking account of building sequence of retaining walls, pre & post backfill of walls and access.

This project would not have been a success without the ability to transfer accurate model data between all stakeholders to achieve agreement on key details with all stakeholders within the constraints of the programme for construction.

What benefits utilizing BIM and Tekla software brought to the project?

- To model the complex geometry of the cover pitch roof trusses. Particularly the node points between the truss chords, truss internals and diagrid members.

- Being able to transfer specific node points Via IFC for visualisation within the Architects Revit model.

- Export accurate part data with multi converter tool for laser cutting of connection components.

- Detailed step by step erection sequence and planning of temporary works by using the phased model to assess the stability of the part erected structure.

- Accurate details for curved top & bottom booms.

The project in numbers

- Floor space in The Vichai Srivaddhanaprabha Building = 11,261 m2

- Tonnes of steel for structural frames on each of the buildings across the site = 1,780

- Timber decking on balconies to the south of The Vichai Srivaddhanaprabha Building = 525m2

- Metal Decking = 6716 m2