Pinnacle were appointed by Shell as Structural Engineering Consultants to help the ongoing review of operational expenditure and maintenance costs of some of their older gas platforms.

Shell have a team who look at the feasibility of de-complexing some of their older platforms to prolong the life span, improve efficiency while reducing on-going maintenance costs. This involves removing any areas of the platform which are no longer required, carrying out any maintenance and replacements of existing areas, such as staircases and handrailing, installing new pipe systems and energy efficient solar panels to reduce the day to day running costs.

This particular gas platform ‘Leman Delta’ is situated in the North Sea some 30 miles (48km) north east of Great Yarmouth. The platform’s original drawings date back to the early 1970’s.

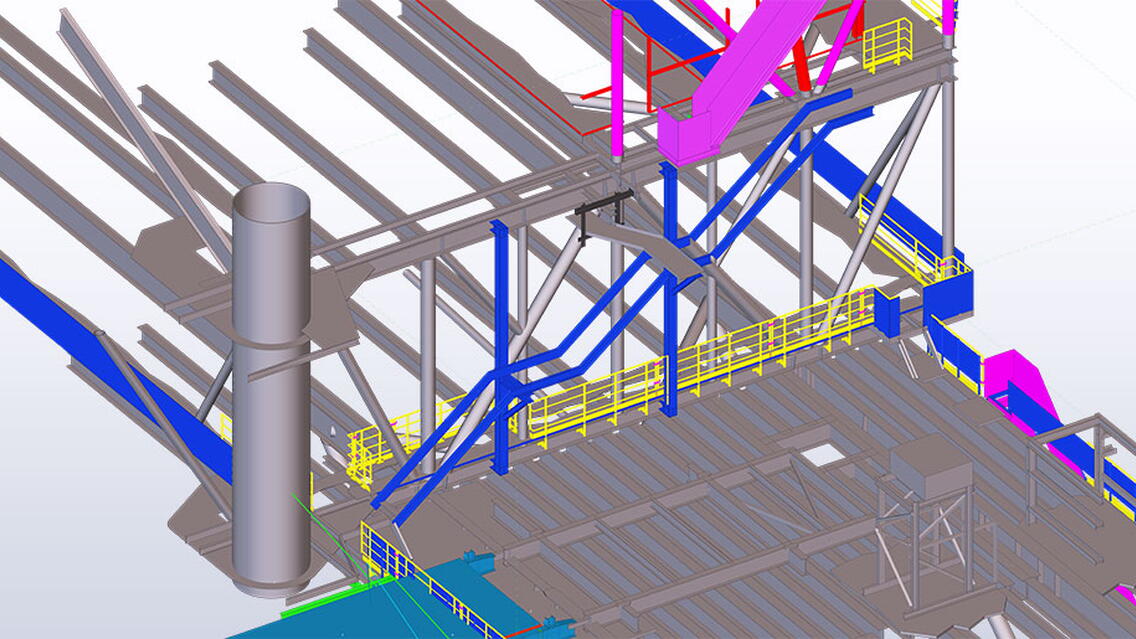

As with any offshore project, safety was paramount. Each scope needed to pass a hazard check to ensure it was in line with current safety regulations. Bolted connections were the preferred method of fixing, welding was to be avoided. The new structural elements had to be installed ‘right first time‘ with minimal site work.

What were the challenges and what made the project successful?

The principal engineering challenges were to work closely with the Shell project team to help them develop their initial program. As the campaign had a limited number of days and the gas platform could only be shut down for a limited time period. We were asked where possible to consider larger lifts to reduce the crane usage and help reduce the overall project time. Some of the areas involved in the de-complexing are as follows:

- Removal of 2 No. Helidecks

- Removal of a Vent Tower

- Removal of 5 No staircases and 4 No. new replacement Staircases to the new specifications

- Removal of Crane Housing & boom

- Removal of the Crane Maintenance Platform

- Removal of existing tanks and electrical containers

- Replacement of large areas of handrail over 3 levels

- Installation of new deck extensions and walk to work and escape gates

- Installation of new Solar Panel frames, Lightning supports and numerous other scopes

We communicated regularly with the Shell construction team listening to their preferred removal sequence and then engineering a solution to best embrace the scheme. There were regular meetings with the local project team either online or face to face. Sometimes we used the Tekla model to lead an online meeting with Dutch suppliers.

We were able to gain a couple of site visits where we could take some site dimensions and take plenty of photographs. We had the use of some of the old as built drawings and a cloud survey scan which proved invaluable in obtaining accurate dimensions. With this additional information, we were able to provide precise drawings for new steelwork and clear instructions for any deconstruction work.

What benefits did utilizing BIM and Tekla software bring to the project?

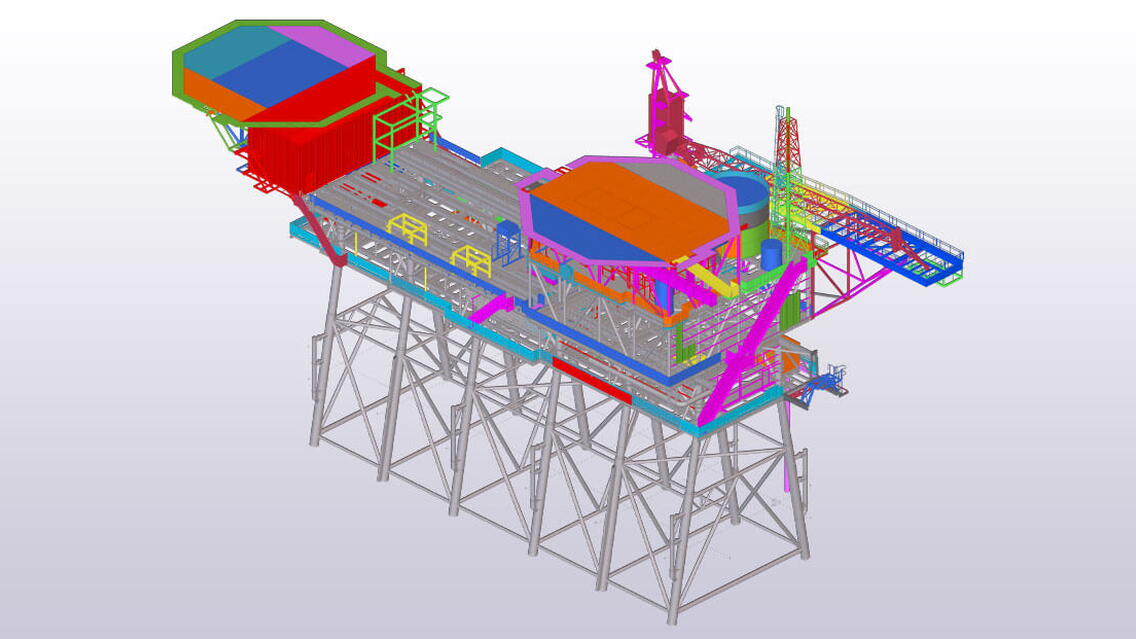

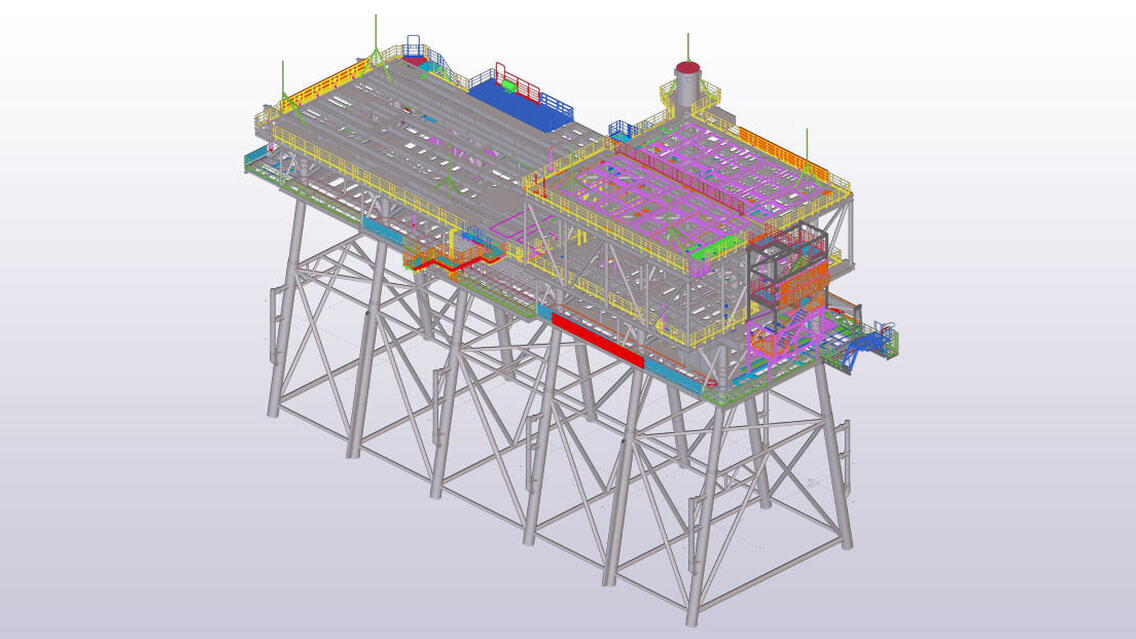

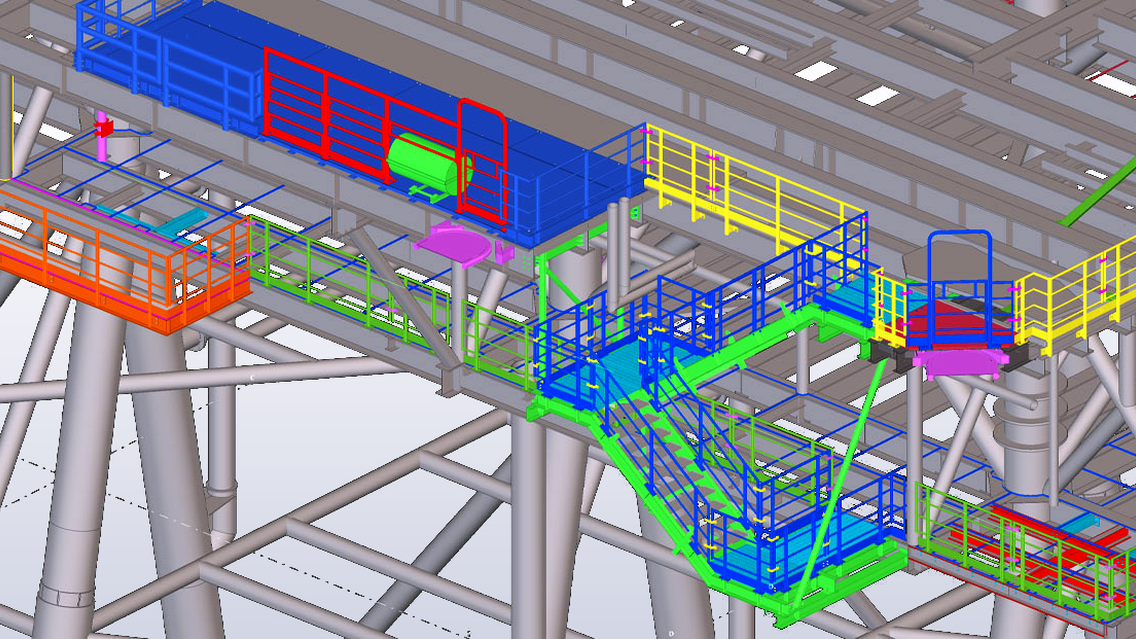

We were able to build up a 3D model using Tekla Structures working from original as built drawings. This initial model then formed the basis for working up our early scheme designs for the structure. The use of Tekla Structures was critical in allowing us to produce weights of various structural elements complete with a centre of gravity for each main lift, whether it was for cut sections of a helideck, a crane boom or a new staircase section. This allowed us to achieve the most efficient lifts while considering the reach and load capacities of the crane, therefore reducing site time.

To help the Shell project team, we were able to issue a weekly BIMsight/IFC model clearly showing our progress with the model. Even though we only have an Engineering license for Tekla Structures, we were able to produce, not only General Arrangement drawings for the destruct work, but also a full set of fabrication drawings including material take off list as required for all the new scopes, over 600 in total. We were able to liaise with the pipework supplier and share information using stp files as they work using PDMS software.

The project in numbers

The first drawings were issued in September 2017 with the final issue in March 2020.

Original overall Platform size:

- Length & width = 98m x 35m

- Height from sea level to top of Vent tower = 47.5m

New overall Platform size:

- Length & width = 68m x 26m

- Height above sea level to the top of the lightning conductors = 35m