A substation is an integral part of the UK electrical transmission system; it reduces electricity voltage so that it is easier and safer to deliver electricity to homes and businesses.

Littlebrook GIS building was required by the client, National Grid, to meet their low carbon objectives. The substation was built in the late 1970s and, as such, was no longer compliant with their low emissions targets. The old substation was heavily reliant of the harmful greenhouse gas, Sulphur Hexafluoride (SF6) which, although it has excellent electrical properties, is extremely harmful to global warming. National Grid aims to eliminate all Sulphur Hexafluoride gas in their works by 2050 so Littlebrook GIS building was required as part of the new 400kV substation.

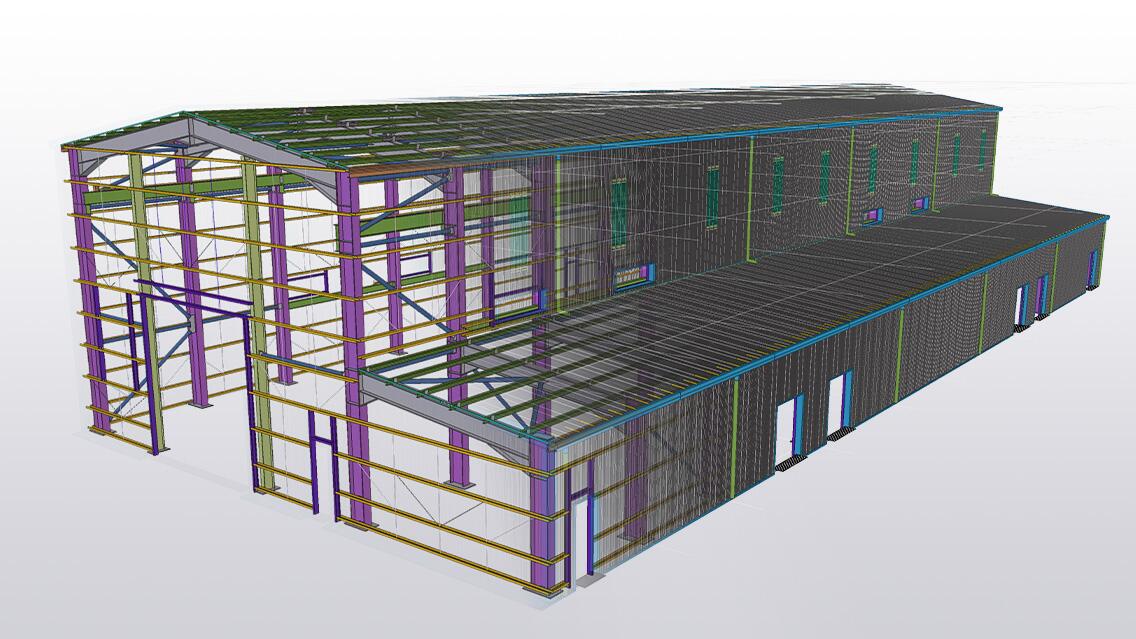

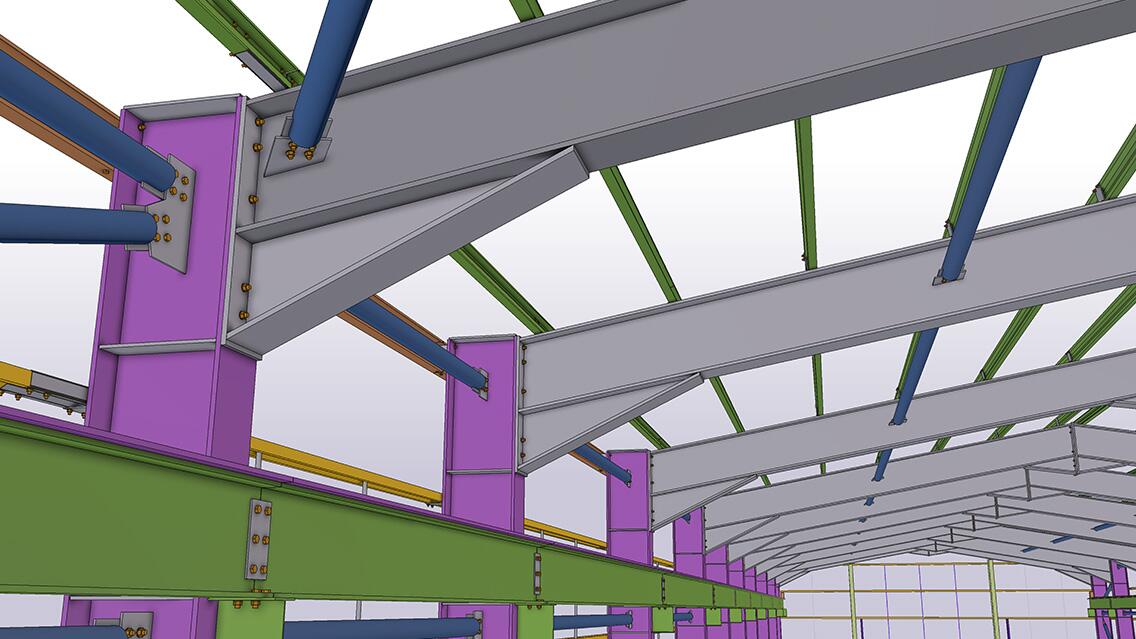

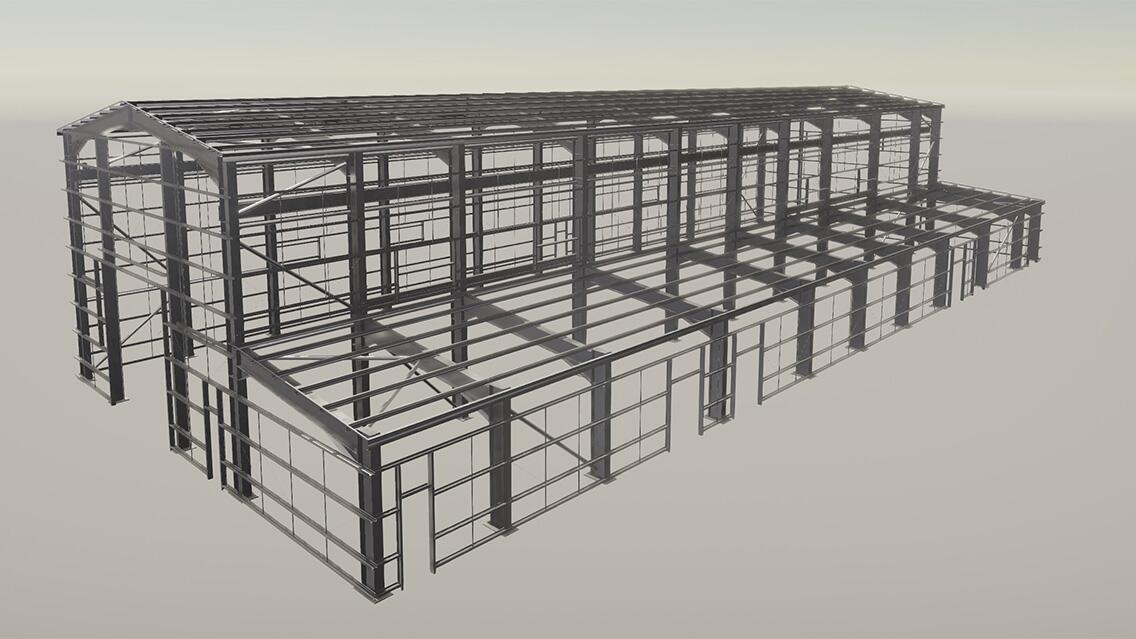

Portal frame and cladding all in one model

The project was successful because we had the portal frame and cladding all in one model. This meant we could perform clash detections to identify any issues that could possibly arise onsite before constructing the building. This was critical to ensuring the project would be delivered on time and on budget.

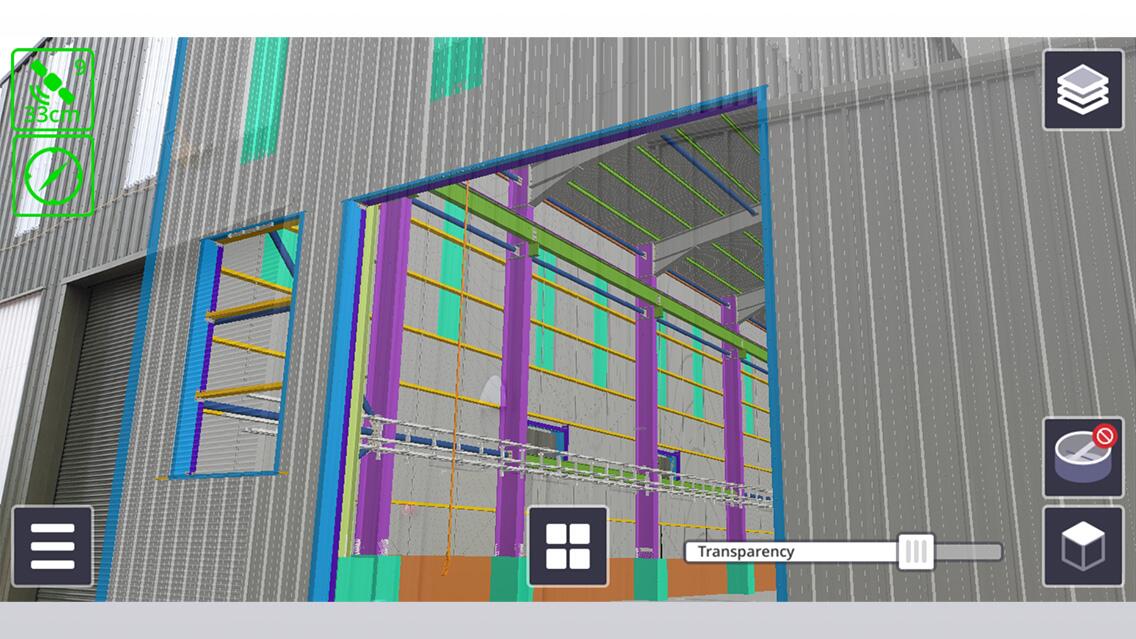

We encountered various obstacles during the project, one of which was the planning permission for the building which had a maximum height. This meant we had to be very specific on what crane was installed inside the building to ensure it had enough clearance on the roof and GIB. We used IFC files from the crane fabricator to position the crane with enough clearance to the roof and GIB, and then designed the connecting steel frame around this. We also had to ensure we could fit the GIB into the building and that all the gas pipes that came in and out of the GIB wouldn’t clash with any new steelwork, we used IFC files to achieve this. Once the frame and cladding was installed, we tested Trimble SiteVision for the first time on this project to ensure the 3D model matched the actual frame, which after a few teething issues worked very well and zero issues were found with the installation.

Important points or benefits:

- Tonnes of steel on the portal frame: 173t

- Parts on the main frame: 2380

- 821m³ of concrete in the slab

- Replacing 1kg of SF6 with 1kg of g3 equals a saving of one car circling the earth four times