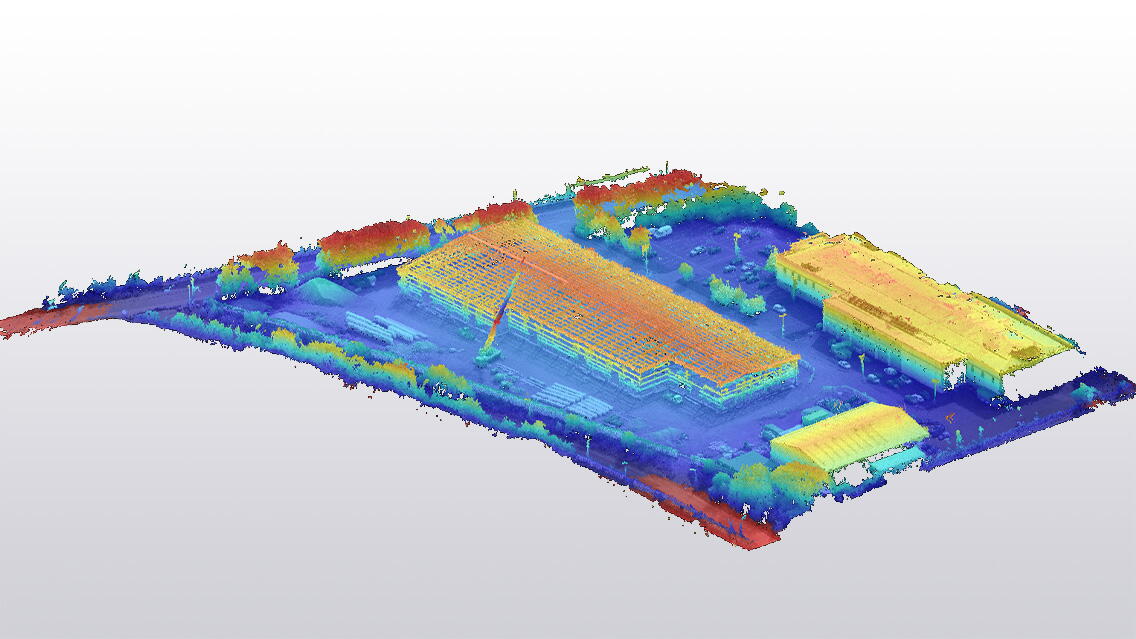

The Nexus Group commissioned BHC with a turnkey project in Hillington: the construction of a state-of-the-art plastic blow moulding facility with integrated office space and a mezzanine level, and inclusive of all fit-out elements, services, infrastructure, drainage, and hard and soft landscaping works.

BHC delivered significant value engineering savings early in the project lifecycle, achieved through the adept use of their in-house skill sets, a hallmark of their turnkey solutions.

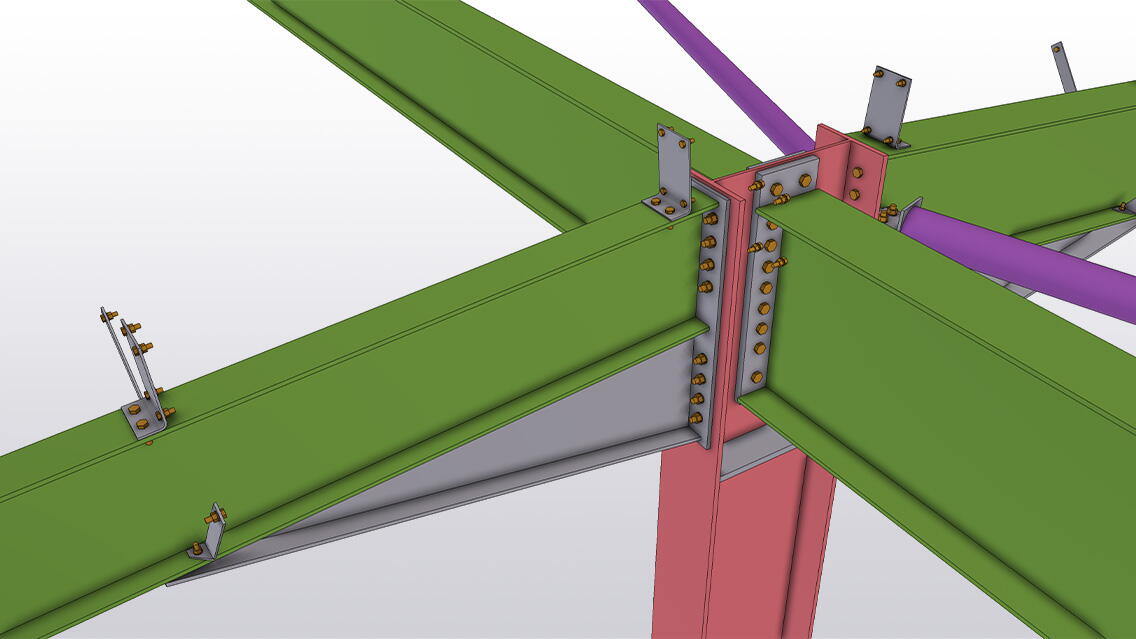

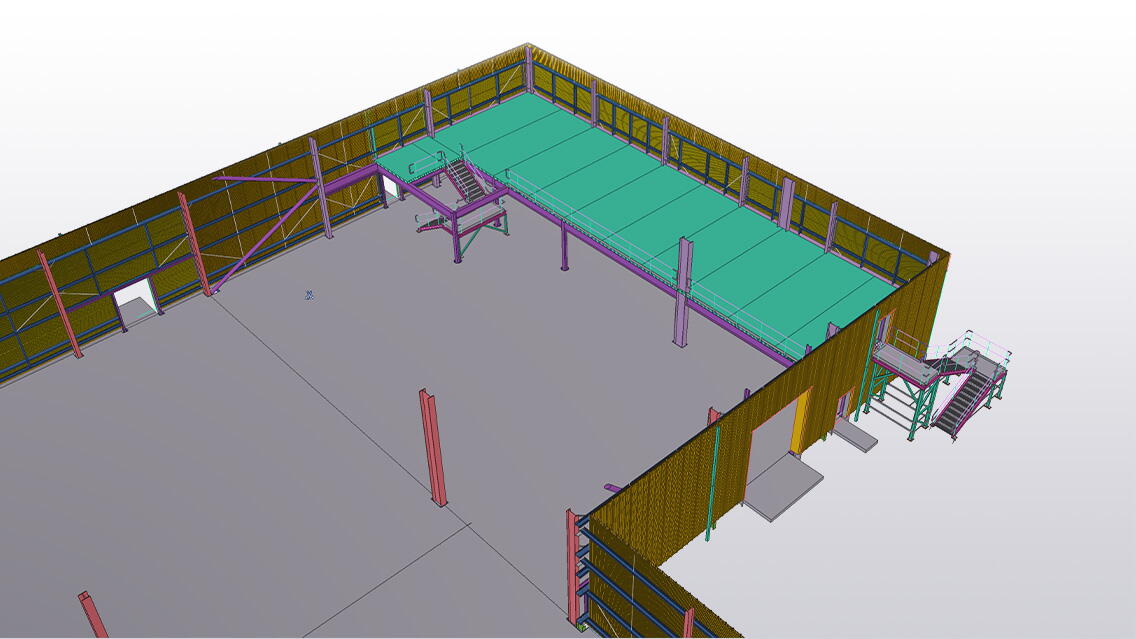

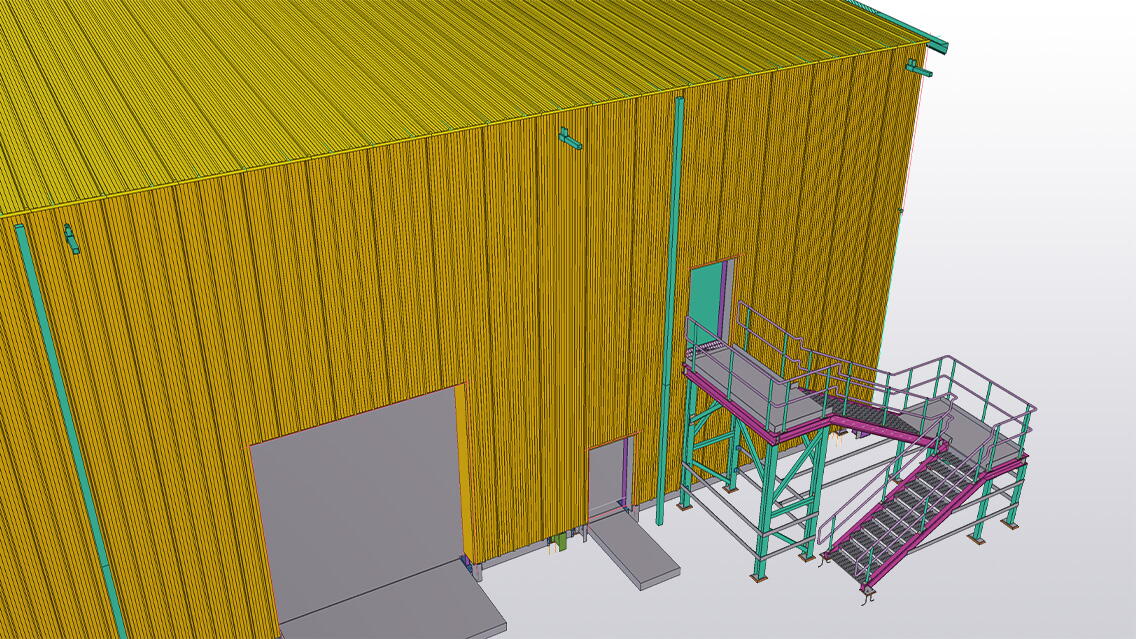

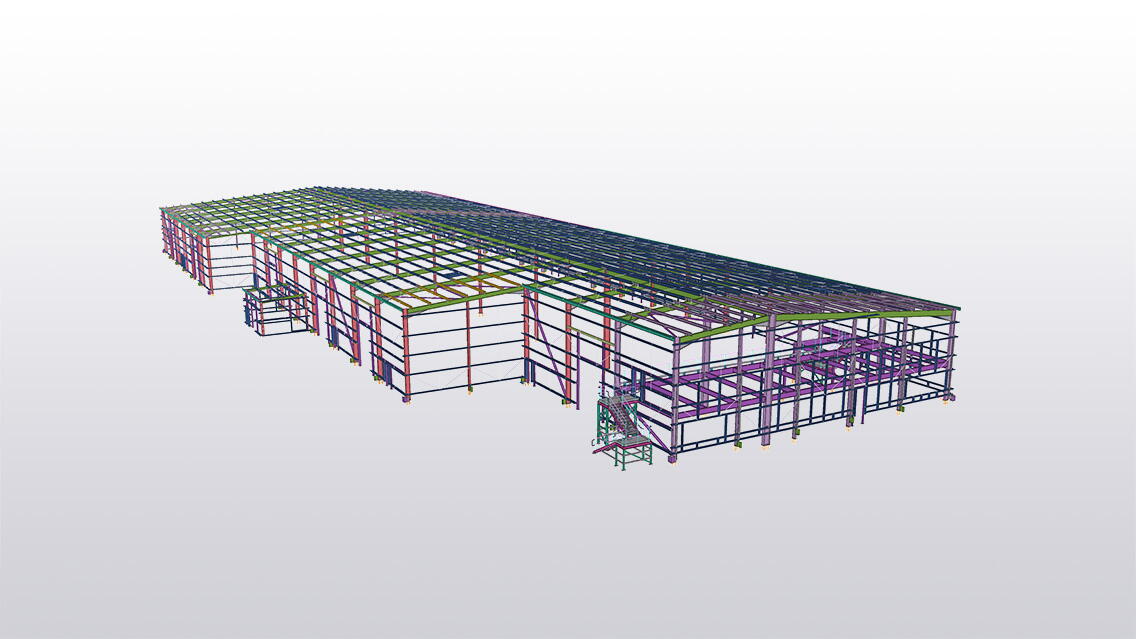

The works involved in this project involved the supply and installation of 510 precast concrete driven piles followed by the installation of BHC’s Valued Engineered Steel Frame, all of which was fabricated in BHC’s own factory controlled environment before being delivered to site. Subsequently, the external roof and wall cladding works commenced, culminating in the pouring of a 5,000m² fibre-reinforced concrete floor.

Internally, office space was created in order to accommodate the future workforce and provide an environment to monitor and control the factory environment.

Challenges and achievements

Tekla was integral in allowing all steelwork and cladding to be in the same model, allowing for accurate detailing and eliminating room for human error. This capability also allowed easy and effective communication of critical aspects, such as fire protection requirements, through the creation of a data-rich model using UDAs.

Using Tekla software

- The 3D model was published to Trimble Connect using the ‘upload with write out’ feature within Tekla, ensuring that the Trimble Connect model was updated in real-time.

- Access to complex assemblies within the 3D model proved invaluable for BHC’s fabrication and construction workforce.

- Custom components were used to add lifting holes and safety holes.

- UDA fields were used to populate the cladding information including: colour, profile, external and internal finish, thickness of insulation. BHC used internal coding for aspects such as the "Track and Trace" system, as well as being able to calculate the embodied carbon in the structure.

- Trimble Connect was used for model reviews and going over cladding details with the site team to find any issues before going to site.

- Tekla Portal frame Designer, Building Designer Masterseries, and Tekla Tedds were used for analysing and designing the structure.