Ingenuity House, as it is named by its owner and Billington’s Client, Interserve, is a 5-storey, 12,000 sq m, highly sustainable, office building located next to Birmingham International Airport and Birmingham International Railway Station. The new build offices are a key element of ‘UK Central’, the region’s regeneration strategy, which will eventually benefit from being connected to high speed railway network HS2. The energy efficient building will bring together circa 1,200 Interserve and RMD Kwikform staff who are currently spread across five separate regional offices.

The project was designed by Architect Sheppard Robson to create a collaborative, inspirational working environment. The exterior is characterised by the building’s stepped structure, creating a strong form that translates into a varied range of internal spaces.

The façade, coupled with the triangular plan of the building, helps create a robust sustainability strategy which allows the design team to target BREEAM Excellent for the building. The overhang of the stepped structure shades the glass, which forms about 35% of the façade, and helps control solar gain whilst maximising natural light, informing the passive sustainability strategy behind the project.

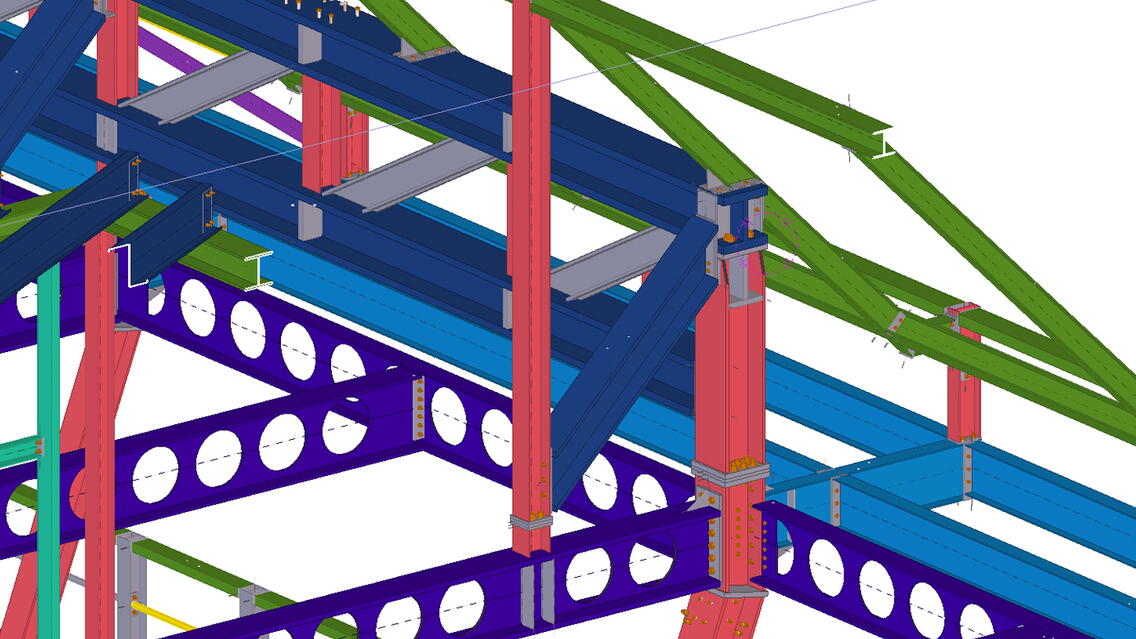

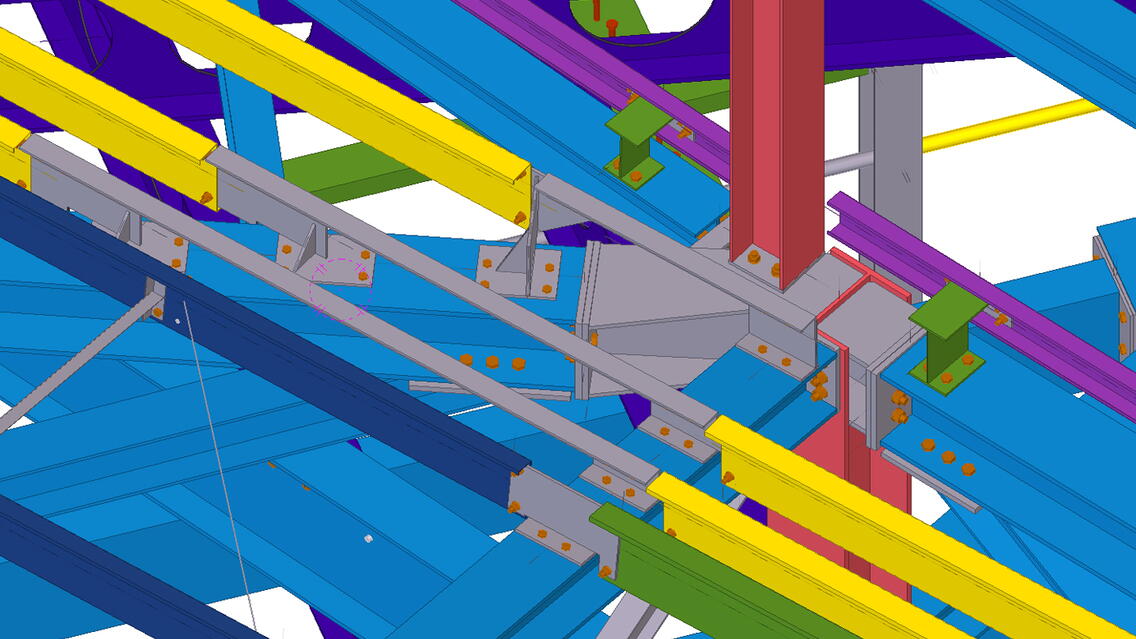

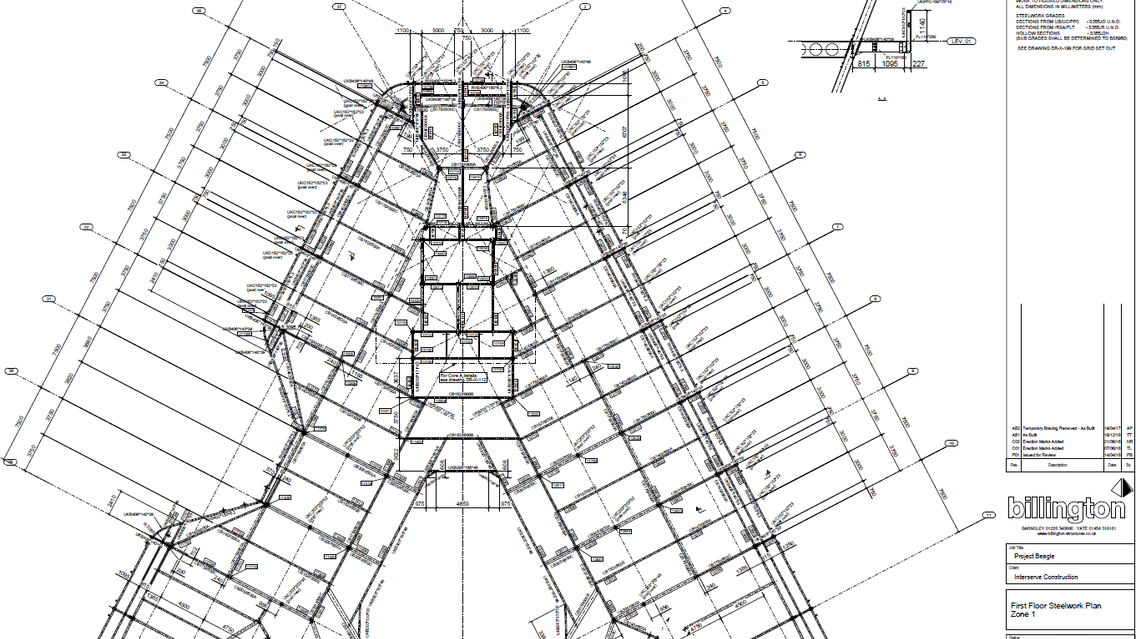

The building consists of large (up to) 3,000 sq m truncated triangular floorplates, which are arranged around a central internal atrium. The structural scheme, designed by Arup, consists of composite concrete deck plates acting as diaphragms taking horizontal forces back to three braced steel cores located at each corner. The floors are supported on composite cellular beams off steel columns founded at basement level. The structure incorporates a suspended ground floor to the atrium and an apron podium structure creating a basement parking area substantially bigger than the building footprint itself. The columns to the external elevations are all substantially raked outward to provide for the Architectural concept. A total of 1,710 tonnes of structural steel supplied and erected by Billington, including a roof level truss, supporting the roof and fourth floor above the feature recessed entrance area, itself weighing in at 30 tonnes. The whole structure is capped off with a lightweight steel atrium roof frame, consisting of trussed radial rafters, inwardly cantilevering from the main roof and propped by a central compression ring in the permanent state.

An additional 35 tonnes of extensive temporary bracing and props were designed and supplied by Billington to control temporary state deflection and facilitate the erection of this unusual and complex structure. Billington’s scope also included design and supply of cold rolled, pre-cast stairs and edge protection. Construction work started in January 2016 with fit-out completion expected by the end of 2017.