The N22 Baile Bhuirne to Macroom project in County Cork was a significant infrastructure project, including the construction of 22 kilometres of dual carriageway. Valued at €280 million, it stands as one of Ireland's largest infrastructure projects to date. Among its notable features are the construction of 21 road bridges, including crossings over the Sullane, Laney, and Bohill rivers.

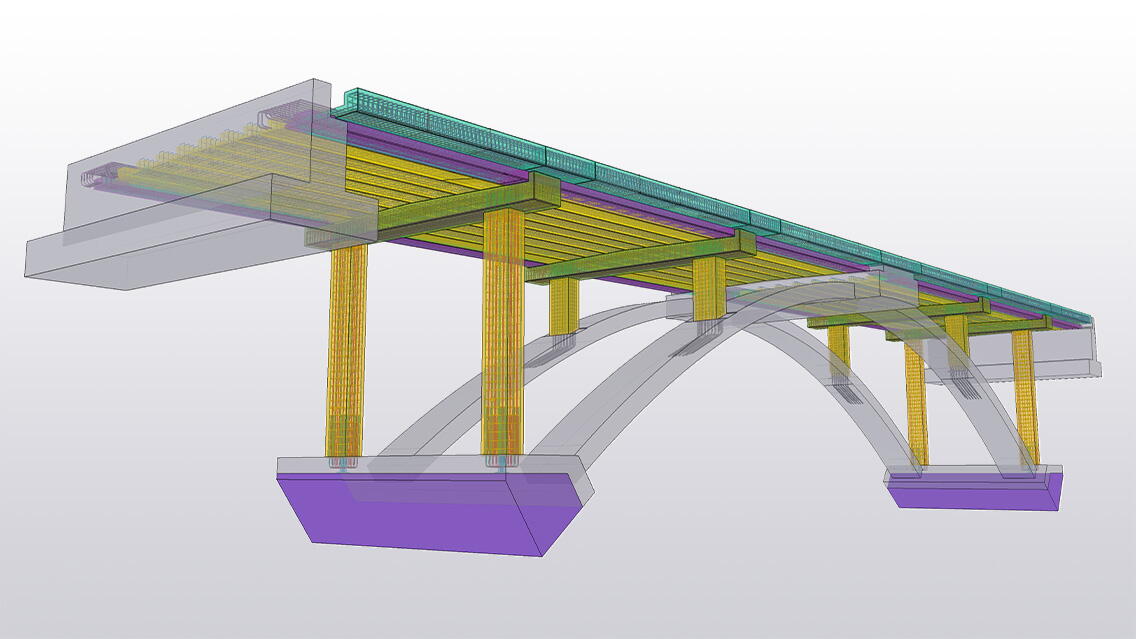

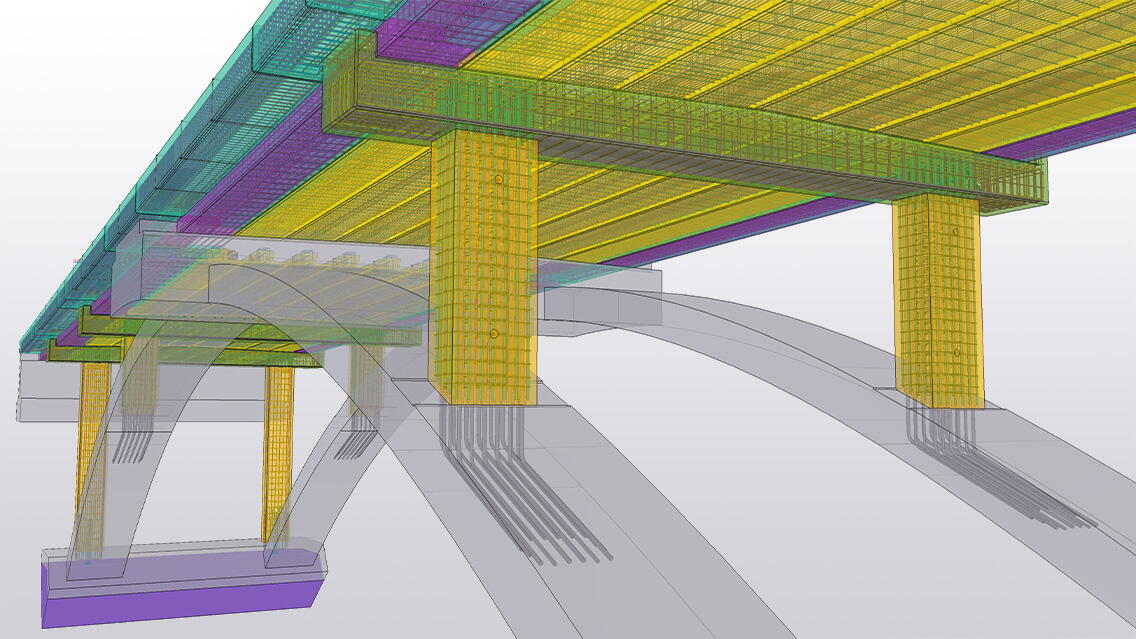

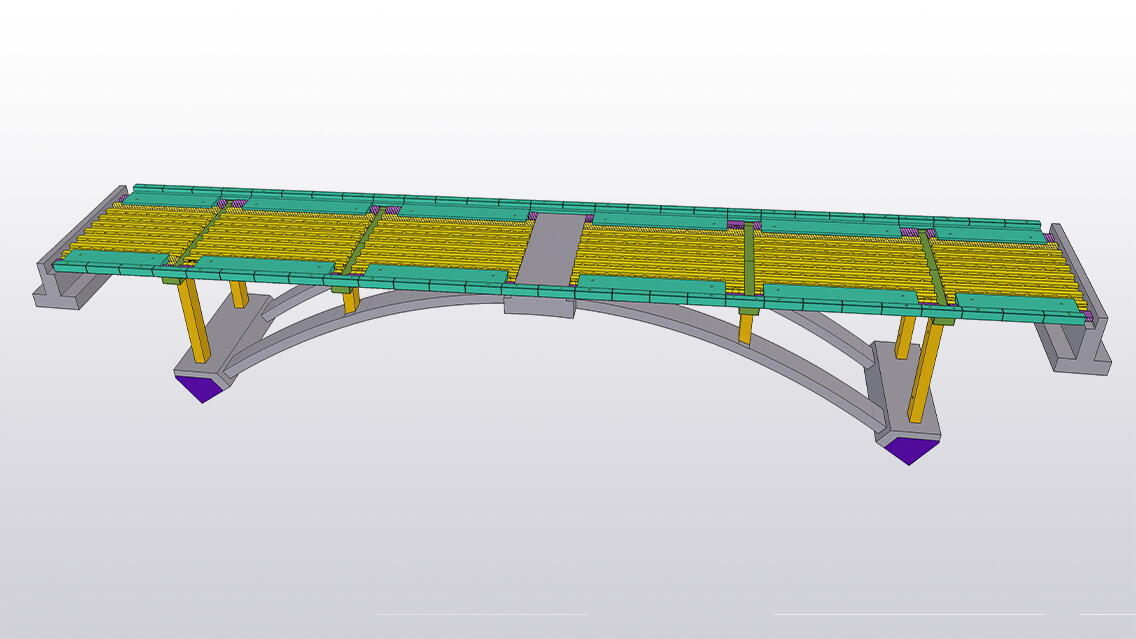

The S02C Combined Accommodation Overbridge, located on the AR07 Access Road north of the existing N22 in County Cork, is a key component of the N22 Scheme. This overbridge spans the N22 Macroom Bypass mainline within a deep rock cut, reaching a clearance of approximately 20 metres above the mainline level. It is characterised by its fully integral arch design, featuring discreet columns and a top deck. With a main arch spanning 44.0 metres and rising 8.0 metres, and approach spans of 8.2 metres on each side, the total deck length measures 64 metres.

What distinguishes this structure from others is both its aesthetics – it seamlessly blends with the surrounding landscape – as well as its innovative approach to utilising both on-site and off-site precast construction methods, the scale of which had not been previously seen in Ireland.

The S02C Combined Accommodation Overbridge project was completed in November 2023, marking a significant milestone in the N22 Baile Bhuirne to Macroom Bypass scheme, with the final section now open to the public.

Challenges and achievements

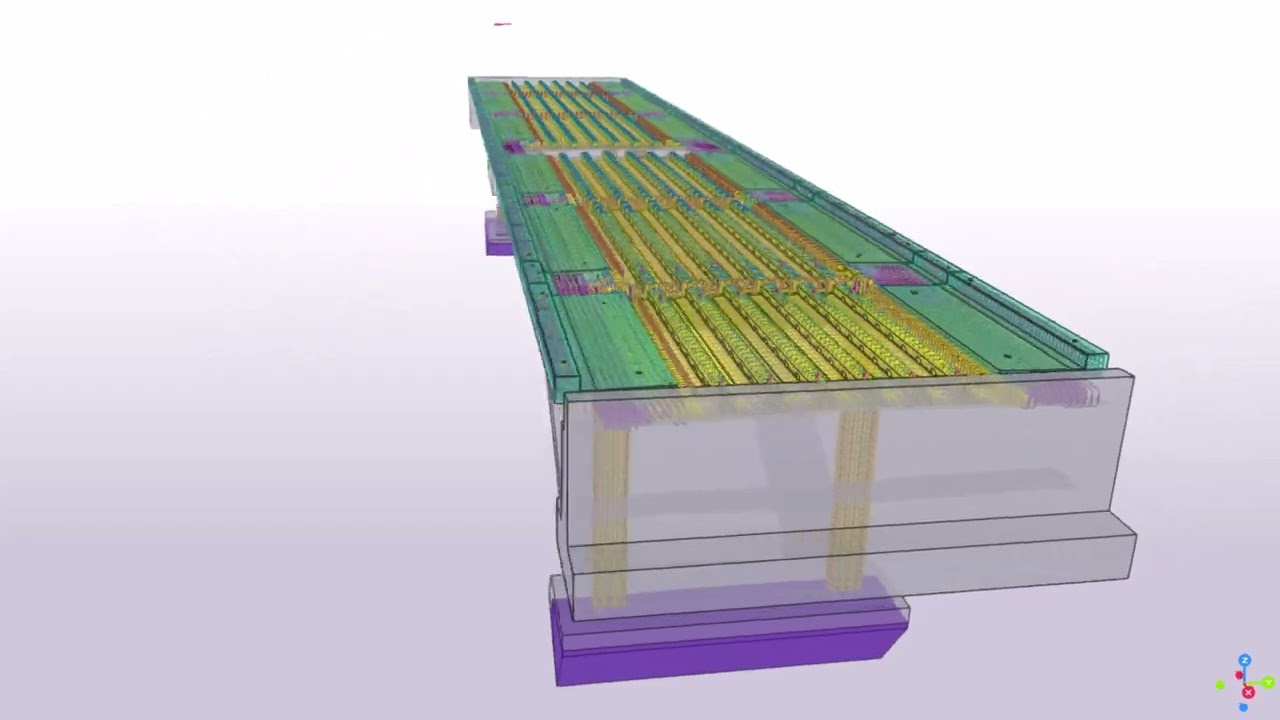

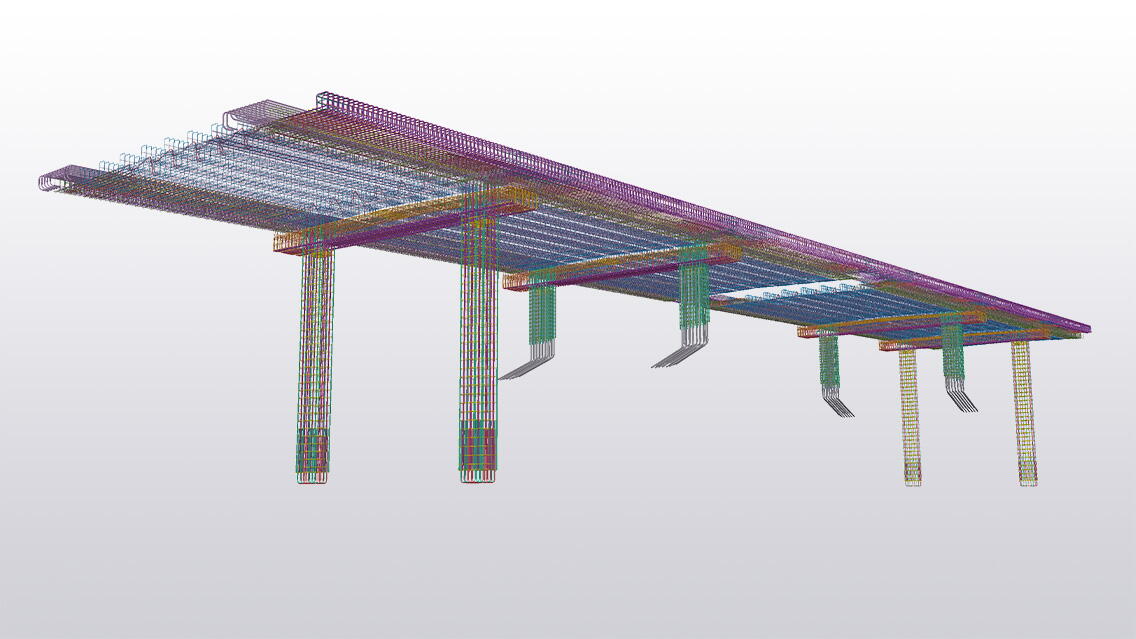

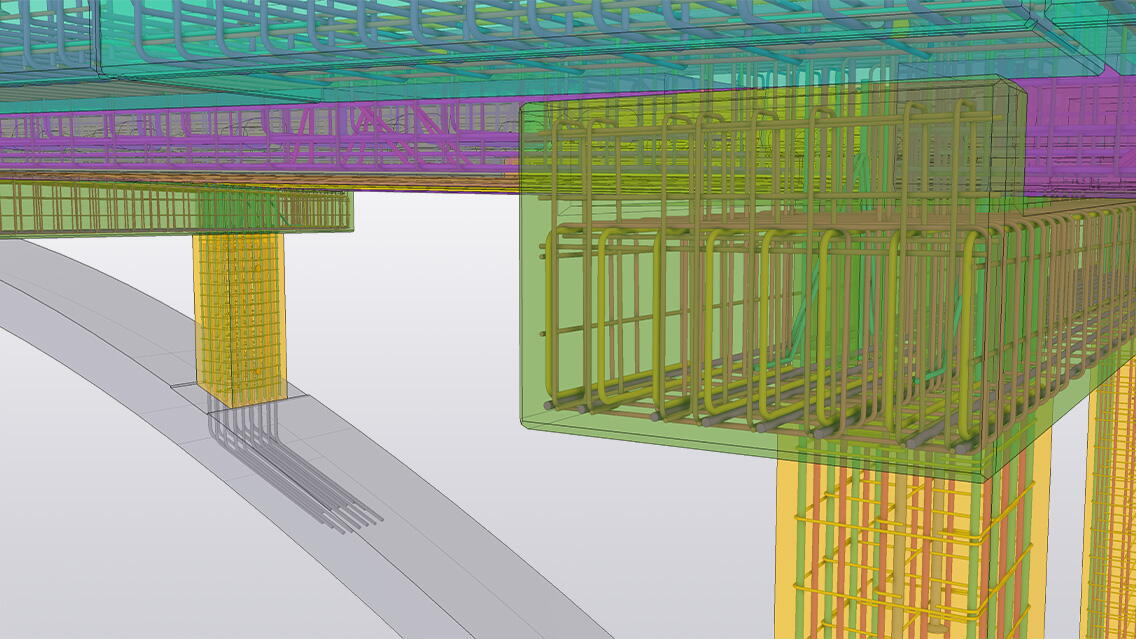

The Banagher Precast team undertook the entire design and detailing process for this project, using Tekla Structures to ensure there were no clashes during assembly, even at a height of 30 metres above ground level. The client was impressed by the team’s precision, and the installation proceeded seamlessly.

Tekla Structures played a crucial role in the S02C Combined Accommodation Overbridge project, enabling the Banagher Precast team to create detailed models and production drawings for all elements with utmost accuracy. Additionally, Trimble Connect was used to provide real-time visualisation of the elements on the factory floor, enhancing coordination and efficiency. The model was also shared with the client to facilitate the installation process and ensure alignment with their requirements.

Using Tekla software

Trimble Connect was used for visualisation of the full model on the factory floor. This process helped the Banagher Precast team to visualise elements being cast, and also spot inconsistencies and omissions, saving time in comparison to standard paper drawing methods.